The whirring and buzzing of your desktop 3D printer can quickly go from fascinating to distracting. But you don’t have to tolerate the noise or relocate your printer to a remote corner of the house.

With some simple DIY skills, you can build an attractive soundproof enclosure that silences the commotion.

Constructing a customized noise-containing box for your 3D printer is an achievable weekend project that pays dividends in enhanced convenience and versatility of desktop 3D printing.

In this step-by-step guide, we’ll walk through planning, building, and finishing an acoustic sanctuary tailor-made for your printer.

Let’s dive in to the materials, construction steps, sealing techniques, and accessories that result in an awesome soundproof enclosure that unlocks new potential for your home 3D printing workflow.

1. Gather Materials

Selecting the right materials is crucial when undertaking a DIY project like building a soundproof 3D printer enclosure.

The primary component will be the plywood that makes up the structural walls and panels.

Baltic birch plywood is an excellent choice due to its multi-ply construction with no voids, stable thickness tolerances, and smooth faces.

The cross-banded structure minimizes expansion and contraction from moisture changes.

High-quality Baltic birch sheets typically utilize better quality lumber without knots or defects that could weaken joints or create voids for noise leakage.

Compare brands and prices from local lumber suppliers and home improvement stores to get the best deal on materials.

For a typical desktop 3D printer enclosure around 24 x 24 x 36 inches, you will need around 4 to 6 full 4×8 sheets of 3/4 inch plywood.

This allows some margin for error and material loss from cutting. Consider purchasing one extra sheet than your calculations call for just in case.

Nothing slows down a project more than running out of materials unexpectedly.

In addition to the plywood, other supplies needed include wood glue, clamps, the viewing window material, hinges, handles, paint or varnish, casters, and hardware like screws, bolts, and nails.

Consult plans and do thorough planning before purchase so you don’t miss anything.

For wood glue, opt for polyurethane varieties like Gorilla Glue that offer very strong bonding power ideal for plywood joining.

Avoid overly gelatinous white glues that can be messier. Gather several pipe or bar clamps at least 3 feet long for pulling together the box sections securely as the glue dries.

Pick up some disposable wood cauls or paint sticks to prevent marring the plywood faces from clamp pressure points.

For the viewing window, acrylic or polycarbonate panels around 1/4 inch thick work well. Look for UV protected and possibly tempered material depending on source location.

Quality hinges and handles are worth the extra cost for smooth operation and longevity. Get all-surface bonding paint formulated for use on wood, metal, and plastics.

Finally, procure heavy-duty 5 or 6 inch locking casters rated for significantly higher weight capacity than your enclosure for smooth transport.

Take time to carefully source quality materials suited for the demands of the project.

2. Cut the Pieces

With all materials procured, you can begin fabrication by cutting the plywood into appropriately sized pieces.

Start by carefully measuring the outside dimensions of the 3D printer itself as well as noting locations of doors, spool mounts, and any accessories.

Scale up the box plans about 6 inches clearance beyond the overall printer size to allow space for overhangs and motions.

Draft detailed drawings indicating the required size and quantity for each panel, allowing for the thickness of the plywood itself.

Double check your math to confirm the cutting plan will yield a properly sized enclosure. Use a framing square, straight edge, and measuring tape to mark cutting lines on the plywood sheets.

Always measure and mark twice to avoid costly cutting errors. If possible, have a helper to manage large sheets on the saw table.

Set up saw horses or a cutting table and secure the plywood from shifting. A circular saw with fresh sharp blade generally provides the cleanest cuts in plywood.

Take the time to align and clamp straightedge guides to ensure straight cuts. Feed the saw slowly and steadily through the cut without forcing or twisting it.

Smaller pieces can be manageable cut using a jigsaw. Leave protective film applied to sheets during cutting to reduce splintering and marring on the faces.

Carefully cut pieces just slightly oversized to provide margin for tuning the fit during assembly. Cut openings for the window, cables, and ventilation passages as marked.

Finally, sand edges smooth and remove any splinters or chips. Repeat the process until achieving all the required plywood components.

3. Assemble the Box

With all of the enclosure panels cut to size, you can move on to the assembly process. There are several techniques to choose from when joining plywood panels into a rigid box structure.

Butt joints with exterior screws are simple but leave fastener heads exposed. Biscuits add alignment and strength while concealing fasteners.

Pocket holes create strong angular joints out of sight. Dado and rabbet joins require precise cutting but create very flat and seamless intersections.

Dowel pegs can be an alternative to biscuits. Experiment to determine which option fits your tools and skills.

Start assembly by dry fitting pieces together before gluing to ensure proper fit. Leave small gaps for adjustment rather than forcing joints.

Use painters tape to hold components square. Check for squareness by comparing diagonal corner-to-corner measurements which should be equal on a box.

Once satisfied, disassemble and use a dust mask when sanding panel mating surfaces while avoiding rounding over edges.

Apply copious wood glue to all joining edges and surfaces and re-attach pieces using your chosen fastening method.

Use bar clamps, pipe clamps, or ratcheting straps to tightly compress joints while the adhesive cures. Wipe away any oozing glue before drying.

Allow the glue to fully harden overnight before removing clamps.

Inspect all seams and joints thoroughly to identify any gaps or steps between panels.

Mark problem areas and disassemble only where needed to fine tune the fit and squareness. Re-sand problematic edges and re-apply adhesive.

Clamp and cure again before moving on. Taking the time to carefully assemble the box avoids major problems down the road.

Once all joints are perfectly mated, drill pilot holes and install wood screws every 4-6 inches around the perimeter for added strength. A helper here makes the process faster and easier.

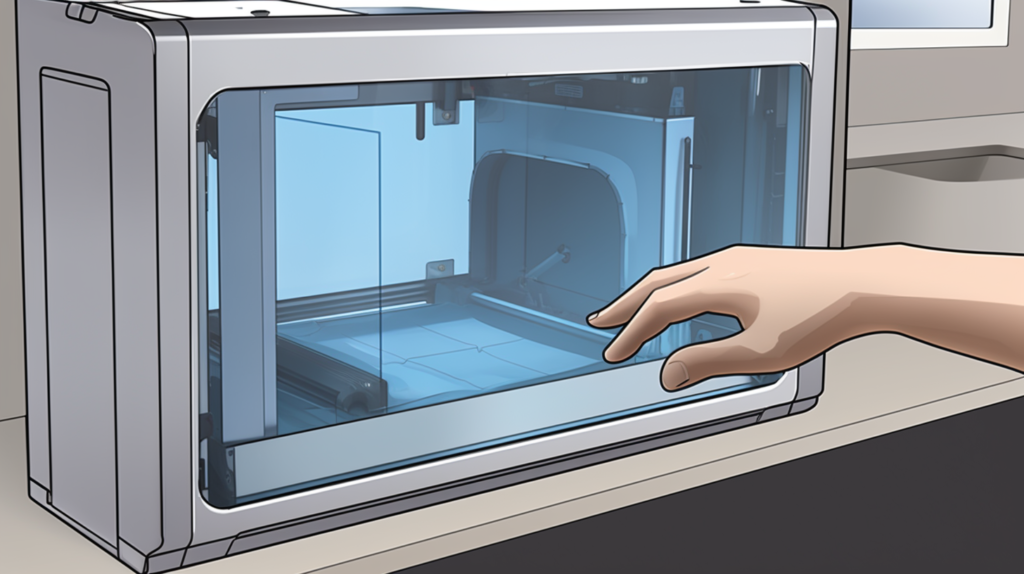

4. Add Viewing Window

One of the most important soundproofing considerations is correctly installing the viewing window into the enclosure.

Measure the dimensions of the window opening in the plywood panel and cut your acrylic or polycarbonate sheet to match as closely as possible.

Center the window pane aligning edges evenly within the opening. Use thick foam weatherstripping tape applied continuously around the interior sides of the window recess.

Test fit the window and trim foam strips to leave a consistent 1/8 inch gap all around between panel and window. This gap allows room for sealing silicone.

Attach hinges and latching handles or sliding latches centered on the left and right sides. Check for smooth operation without binding.

Pre-drill and install exterior plywood trim using weatherproof wood screws to cover hinge and latch bases.

Mask 1/2 inch perimeter of window pane using painter’s tape. Thoroughly clean and degrease the contact surfaces between window and enclosure.

Apply a thick bead of clear 100% silicone caulk around the window recess perimeter. Tool the silicone evenly into the gap to fully seal the interface.

Remove masking before silicone begins to skin over. Finally install acoustic damping rubber strips around the window to compress against pane edges.

The combination of flexible sealing techniques isolates noise and vibration passed through the window.

5. Apply Finish

Applying appropriate finish to your enclosure serves dual purposes of weatherproofing the plywood while also enhancing sound deadening performance.

Begin by a final light sanding of exterior surfaces using 240 grit sandpaper to remove any marks or roughness.

Use a tack cloth to thoroughly remove dust that could impede finish bonding. Wipe all surfaces to be finished with a degreasing solvent using disposable rags. Allow to fully evaporate before finishing.

For painting, thin consistencies yield the best results by helping the paint fully penetrate the wood grain before building uniform coats.

Apply two primer coats using thin foam rollers and allowing proper drying time between each application.

Lightly sand again with fine (320-400 grit) sandpaper to create a smooth base for painting. Finish with 2-3 topcoats of satin, eggshell, or semi-gloss paint thinned 10-15% with the appropriate solvent.

Sand very lightly between coats to level and de-nib. Carefully monitoring paint thickness avoids drips or runs which ruin the final appearance.

An alternative is using an oil based penetrating stain followed by water based polyurethane varnish. Work the stain thoroughly into the plywood using lint-free rags or applicators.

Allow to fully cure before sealing with three thin applications of satin or semi-gloss polyurethane varnish.

Lightly sand and wipe clean between each coat. Oil based finishes enhance the natural wood visual characteristics while providing exceptional durability.

Take time with finishing for professional looking results that stand the test of time.

6. Install Printer

With construction and finishing of the enclosure itself complete, it’s time to install the 3D printer and accessories inside.

Start by preparing a vibration dampening base for the printer to sit on. Mix and pour a slab of fine gravel concrete 1-2 inches thick into the bottom of the enclosure.

Allow this to fully cure over at least 5-7 days before proceeding. Alternatively, precisely cut dense foam sheets to fit the floor space.

Next, place the 3D printer in the desired location and shim as needed to level it. Mark locations for drilling mounting holes into the concrete or foam base.

Remove the printer and drill appropriate pilot holes for hardware anchors or lag bolts. Clean out the holes fully.

Carefully replace the printer, aligning with the mounting points. Insert anchors and attach the printer securely using bolts and washers.

Check for level on all sides and adjust mounting positions if needed for optimum leveling.

The combination of a heavy static base and secure printer mounting prevents noise-causing shifts or vibrations.

Route and extend cables to pass through small holes lined with acoustic damping grommets. Avoid running cables through unsealed openings.

Attach the extended cables to outlets mounted externally on the enclosure rear. Use cable anchors, ties, and wraps to neatly bundle and secure wiring out of the way along the enclosure sides.

Test printer motions ensuring adequate slack without pulling or pinch hazards. Handle cables carefully to avoid transmission of motor noise to the enclosure.

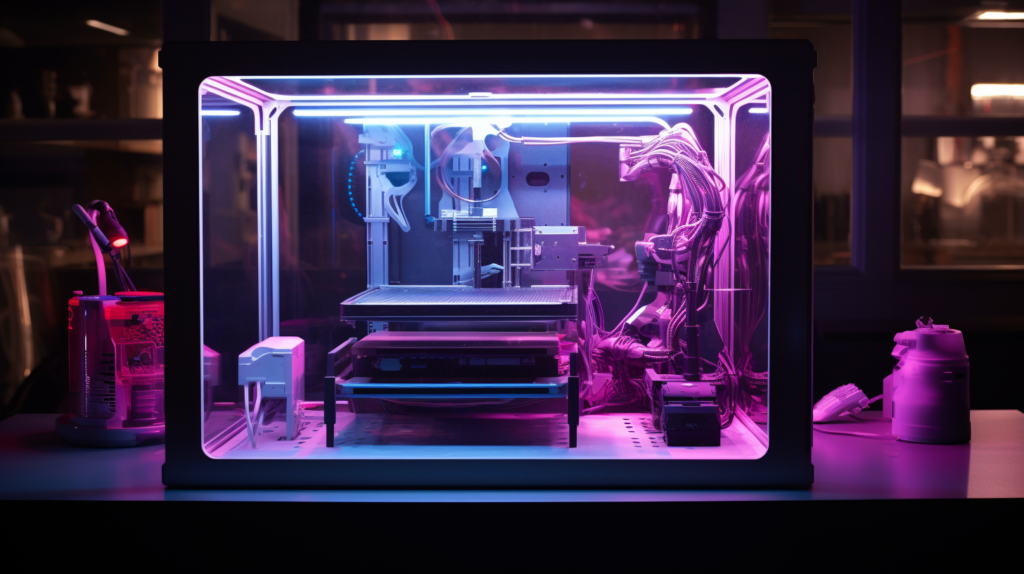

7. Add Accessories

Now is the time to install additional accessories and components to complete the printer enclosure.

Attach spool holders mounted to the enclosure ceiling to keep printing filament organized and feed cleanly into the printer.

Incorporate power strips and multi-outlet extensions for plugging in the printer, lighting, cameras, controllers, or any other electronic devices.

Make or purchase specialized storage containers and tool holders to keep nozzle wrenches, wire brushes, alcohol pads, gloves, and other supplies readily at hand when needed.

LED strip lighting around the top interior perimeter provides bright illumination of the build area. Dimmable lighting allows adjusting intensity as desired.

For safety, include a spring-loaded fire suppression canister rated for electrical fires.

Optional accessories like HEPA filtered ventilation, humidity control, automatic bed leveling, camera monitoring, and remote operation allow taking the enclosure capabilities even further.

Carefully drill and install ports in the rear panel for routing cables/wiring to optional accessories mounted externally.

Pay close attention to acoustic isolation details so that add-ons don’t compromise the overall noise containment.

Outfitting the enclosure fully caters to all needs for the printer enclosed inside. Invest time to make the space as efficient and useful as possible.

8. Make It Mobile

Due to the considerable combined weight when fully loaded, installing casters makes relocating the enclosure much simpler.

Bolt heavy duty casters rated to double the total expected weight to the bottom corners of the enclosure. Position wheels toward the rear with fixed glides at the front.

This prevents tipping while allowing tilting the enclosure backward to roll around as needed. Ensure all 4 wheels touch floor simultaneously to properly distribute weight.

Lock wheels once positioned to prevent shifts during printing. For maneuvering, attach fold-down handles centered high on each side.

Gripping these handles allows carefully tilting and rolling the enclosure through doorways and over thresholds.

Take care to avoid tipping during transport. A spotter assisting provides an extra measure of control.

Sturdy wheels and handles allow safely and easily moving the substantial completed enclosure assembly to any space as required.

Tips for Soundproofing

Achieving excellent acoustic isolation for your DIY 3D printer enclosure requires nuanced attention to certain soundproofing principles.

Eliminate any air gaps allowing sound transmission by fully sealing the enclosure. Apply flexible acoustic caulk around the viewing window, cable ports, joints, corners, and penetrations.

High density insulating foam panels on walls absorb internal sound reverberations. Cut panels precisely and wedge tightly into corners.

Concrete or foam bases isolate vibration transfer. Rubber acoustic mats under the printer feet block resonance into the floor.

Allow minimum ventilation openings for airflow using baffles. Keep the window shut whenever printing.

Building proper soundproofing into the design from the beginning results in exceptionally quiet performance.

With diligence and proper techniques, you can construct a 3D printer enclosure that effectively contains noise and looks fantastic.

Your DIY enclosure will not only benefit your own working environment but also allow you to install the printer in spaces like classrooms and offices much more comfortably.

Putting meticulous effort into planning, assembly, sealing, finishing and outfitting the enclosure will reward you with years of optimal function and aesthetic enjoyment.

Follow this guide closely and don’t cut corners. Building your own well-designed soundproof enclosure unlocks new possibilities and conveniences for your desktop 3D printing experience.

Conclusion

Constructing your own noise-containing enclosure for a desktop 3D printer is an involved but gratifying project.

With care and patience, you can build an acoustic sanctuary that allows operating the printer in any environment while eliminating disruptive noise.

Follow the steps outlined here to plan, source, build, finish, seal, and outfit an enclosure tailored to your specific printer model.

Invest time in assembly and soundproofing techniques for optimal results. Operating your printer in a custom sound-controlled enclosure makes the technology more versatile and user-friendly.

Applying your own hands-on skills nets a high-quality enclosure and provides great learning experiences.

So don’t hesitate to undertake this DIY venture – the effort pays dividends with a silent, effective, and great-looking enclosure that enhances your 3D printing workflow for years to come.