When it comes to improving the acoustics of a room, whether it’s a recording studio, home theater, or music practice space, the choice between acoustic foam and acoustic wedges is a common dilemma.

While both materials are made from polyurethane foam, their designs and properties can significantly impact their effectiveness, cost, and overall performance.

This article delves into a comprehensive comparison of acoustic foam and acoustic wedges, exploring their strengths and weaknesses across various aspects, including sound absorption, density, surface area, frequency range, aesthetics, and cost.

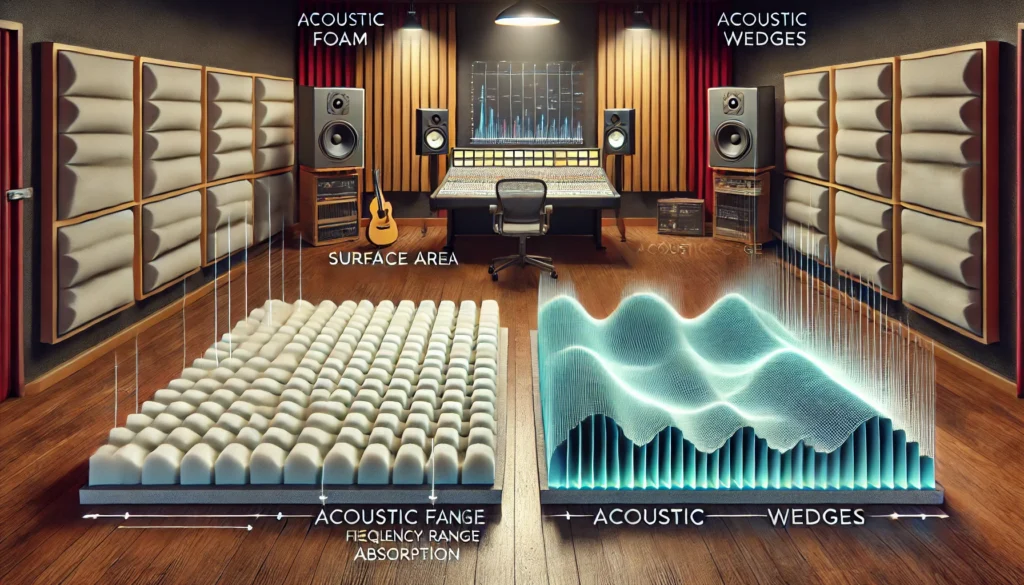

Acoustic Foam vs. Acoustic Wedges: Which Is Better?

The quick answer is that Acoustic wedges are better than acoustic foam because their increased thickness allows for deeper sound absorption, especially for low frequencies.

The higher density foam used in acoustic wedges absorbs more sound energy and reduces reverberations more effectively than typical acoustic foam panels.

Additionally, the V-shaped profile of wedges creates more surface area to trap and diffuse a wider range of frequencies from lows to highs.

This design advantage makes acoustic wedges particularly well-suited for professional audio environments like recording studios and home theaters where comprehensive frequency control is essential.

Beyond performance, acoustic wedges also offer a professional look and visually appealing design that can enhance the aesthetics of a creative workspace.

While more expensive upfront, their superior acoustic properties and durability make them a longer-lasting, worthwhile investment compared to basic acoustic foam treatments.

For those prioritizing optimal sound absorption across all frequencies, pro-level acoustics, and an aesthetic listening environment, acoustic wedges from top brands like Auralex are simply the superior choice over acoustic foam panels.

We explore this in details in this article to allow you to fully understand more.

1. Thickness & Sound Absorption

Acoustic Foam

Acoustic foam panels come in various shapes, such as flat panels, pyramids, and egg crates.

These shapes are designed to increase the surface area and improve sound absorption by trapping sound waves and reducing reflections.

However, flat foam panels are often thinner, which can limit their ability to absorb sound effectively, especially in the lower frequency ranges.

Acoustic Wedges

One of the key advantages of acoustic wedges is their thickness.

Due to their V-profile design, acoustic wedges often come in thicker profiles, which enhances their ability to reduce reverberations and improve overall sound absorption.

The increased thickness allows for deeper penetration of sound waves, resulting in more effective absorption and less reflection.

A thicker material can better absorb low-frequency sound waves, which have longer wavelengths and require more material to be effectively absorbed.

Acoustic wedges, with their greater thickness, excel at capturing these longer wavelengths, making them a superior choice for rooms where lower frequency absorption is essential, such as home theaters or music studios.

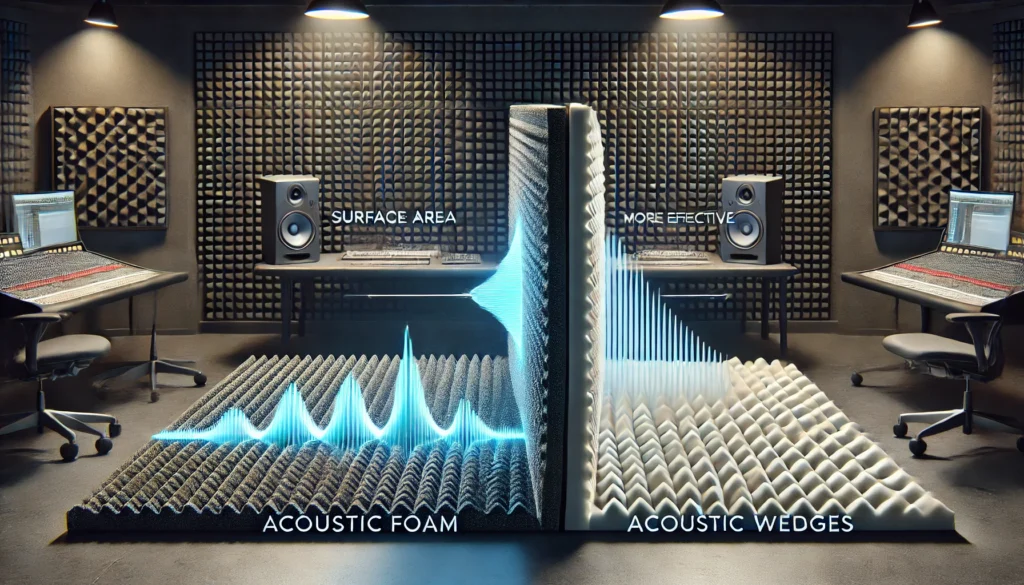

2. Density and Sound Energy Absorption

Acoustic Foam

The density of acoustic foam plays a crucial role in its effectiveness at absorbing sound energy.

Standard acoustic foam panels may not always have the density required to absorb a significant amount of sound energy, which can limit their ability to reduce reverberations and control the acoustic environment effectively.

Acoustic Wedges

Acoustic wedges are typically made from denser foam, which can absorb more sound energy, making them more effective at reducing reverberations and controlling the overall acoustic environment.

This is why high-quality brands like Auralex, which use denser foam materials, are more effective at sound absorption than standard acoustic foam panels.

Denser foam materials have a higher mass, which helps in dampening sound waves more effectively, leading to a quieter and more controlled acoustic environment.

The increased density allows the material to dissipate more of the sound energy into heat, rather than reflecting it back into the room.

It’s important to note that while denser foam is generally more effective, there is a point of diminishing returns.

Excessively dense foam can become too rigid and lose its ability to absorb sound effectively.

Manufacturers must strike a balance between density and flexibility to achieve optimal sound absorption performance.

3. Surface Area & Frequency Range

Acoustic Foam

While acoustic foam panels come in various shapes, such as pyramids and egg crates, to increase their surface area, flat panels may not be as effective at absorbing a wide range of frequencies.

Their design can limit their ability to trap and diffuse sound waves efficiently, particularly in the mid and high-frequency ranges.

Acoustic Wedge

The V-profile design of acoustic wedges increases the surface area even more than traditional acoustic foam shapes, making them particularly effective at absorbing mid to high frequencies.

The wedge shape allows for more efficient sound wave trapping and diffusion, making them a popular choice for recording studios, home theaters, and other environments where sound quality is paramount.

The increased surface area provided by the V-profile design helps to capture and absorb sound waves more effectively, reducing echoes and creating a more balanced acoustic environment.

This design feature is especially beneficial for rooms with hard, reflective surfaces, where mid and high-frequency sound waves can bounce around and cause unwanted reverberations.

Additionally, the combination of thickness and surface area of acoustic wedges allows them to effectively absorb a wider range of frequencies, from low to high, making them a versatile solution for various acoustic applications.

4. Aesthetics and Professional Appearance

Acoustic Foam

Both acoustic foam and wedges come in various colors and designs, allowing for customization based on aesthetic preferences.

However, flat foam panels may not offer the same visual appeal as more intricately designed options, which can be a consideration for spaces where aesthetics are important.

Acoustic Wedges

Wedges, with their distinctive V-profile, can add a professional look to studios and recording spaces.

Their unique design not only enhances sound absorption but also contributes to the visual appeal of the room.

Acoustic wedges can make a space look more professional and inviting, which can be particularly important in creative environments where aesthetics matter.

Many manufacturers offer acoustic wedges in various colors and patterns, allowing users to choose options that complement the overall design of their space.

Additionally, some wedges are available with fabric coverings, further enhancing their aesthetic appeal and providing a more polished look.

It’s worth noting that while aesthetics are important, they should not be the sole deciding factor when choosing between acoustic foam and wedges.

The primary consideration should be the acoustic performance requirements of the space, and then aesthetics can be factored in as a secondary consideration.

5. Cost & Value

Acoustic Foam

Acoustic foam panels are generally more affordable than acoustic wedges, making them a popular choice for those working with limited budgets.

However, it’s important to remember that cheaper options may not always provide the same level of acoustic performance as more expensive, high-quality materials.

Acoustic Wedges

Acoustic wedges tend to be more expensive than acoustic foam panels, primarily due to the increased material density and design complexity.

However, the higher cost is often justified by their superior sound absorption capabilities, wider frequency range coverage, and overall acoustic performance.

When considering the cost of acoustic wedges, it’s essential to view them as a long-term investment.

While the initial outlay may be higher, the improved acoustic environment and enhanced sound quality can provide significant benefits, particularly in professional settings where audio quality is paramount.

Additionally, it’s important to consider the overall value proposition of acoustic wedges.

While they may be more expensive upfront, their superior performance and longer lifespan can make them a more cost-effective solution in the long run, especially for spaces that require high-quality acoustic treatment.

6. Installation & Placement

Acoustic Foam

Acoustic foam panels are generally lightweight and easy to install, often requiring only adhesive or mounting hardware.

However, their effectiveness can be influenced by their placement and coverage within the room.

Proper placement and coverage are crucial to ensure optimal sound absorption and acoustic performance.

Acoustic Wedges

Acoustic wedges, due to their increased thickness and density, can be heavier and more challenging to install compared to acoustic foam panels.

In some cases, specialized mounting hardware or professional installation may be recommended to ensure proper placement and secure attachment.

When it comes to placement, acoustic wedges are often used to treat specific areas or surfaces within a room, such as walls, corners, or behind speakers, where their increased thickness and surface area can be most effective.

Proper placement and coverage are essential to maximize their sound absorption capabilities and achieve the desired acoustic environment.

It’s important to note that both acoustic foam and wedges may require additional acoustic treatment, such as bass traps or diffusers, depending on the specific requirements of the space and the desired acoustic characteristics.

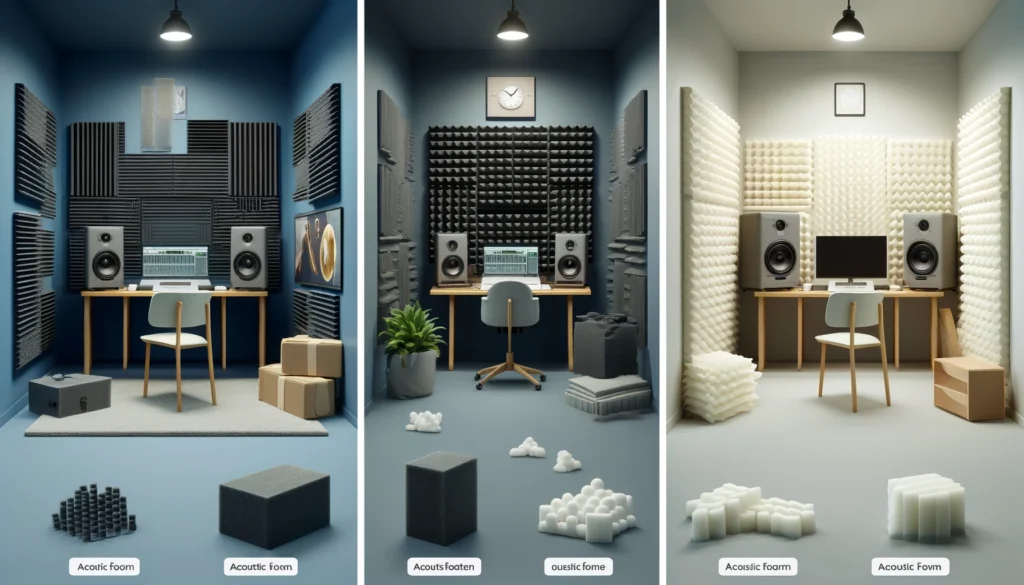

7. Application-Specific Considerations

Recording Studios and Music Rooms

In recording studios and music practice rooms, acoustic wedges are often the preferred choice due to their superior sound absorption capabilities, particularly in the mid and high-frequency ranges.

Their increased thickness and density also make them effective at controlling low-frequency reverberations, which can be crucial for achieving clean and accurate recordings.

Home Theaters and Media Rooms

For home theaters and media rooms, both acoustic foam and wedges can be effective solutions.

However, acoustic wedges may be more suitable for larger spaces or rooms with challenging acoustic conditions, as they can provide more effective sound absorption and control across a wider frequency range.

Offices and Workspaces

In office environments and workspaces, acoustic foam panels may be a more cost-effective option for basic sound absorption and noise reduction.

However, if the space requires more advanced acoustic treatment or has specific acoustic challenges, acoustic wedges may be a better investment.

Conclusion

In conclusion, while both acoustic foam and acoustic wedges are effective at improving room acoustics, acoustic wedges excel in several key areas, including thickness and sound absorption, density and sound energy absorption, surface area and frequency range, and aesthetics and professional appearance.

Acoustic wedges, with their increased thickness, density, and surface area, provide superior sound absorption across a wider range of frequencies, making them a more effective solution for professional audio environments, recording studios, and home theaters.

While they are more costly than acoustic foam panels, brands like Auralex offer superior performance, making them a worthwhile investment for applications where high-quality acoustic treatment is essential.

However, acoustic foam panels can still be a viable option for those working with limited budgets or in spaces with less demanding acoustic requirements, such as offices or smaller rooms