Do you cringe from noisy neighbors and thin apartment walls that pass sound too easily?

R13 insulation could be a budget-friendly soundproofing solution worth exploring.

R13 insulation provides moderate sound dampening by restricting airflow and adding fiberglass density inside cavities to absorb noise when correctly installed. Performance improves supplemented.

Let’s dive into the noise blocking capabilities and limitations of R13 insulation to see if it meets your needs…

What Is R13 Insulation?

R13 insulation refers to insulation that has an R-value of 13. The R-value is a measure of an insulating material’s ability to resist heat flow.

The higher the R-value, the better the insulating performance. R13 fiberglass insulation resists heat flow moderately well.

It is one of the most common and cost-effective types of insulating materials used in home construction in walls, floors, and attics.

R13 insulation usually comes in the form of flexible fiberglass blankets or batts.

The batts are available in various widths designed to match standard wall stud spacing. R13 batt insulation is made from extremely fine glass fibers bonded together with a thermosetting resin.

The fibers trap air pockets that provide the actual insulating properties. The more air pockets, the better the heat insulating qualities.

Is R13 Insulation Good For Soundproofing?

Yes, R13 insulation is good for soundproofing. The same properties that help R13 insulation resist heat flow also enable it to block sound transmission.

The dense packing of glass fiber batts resists airflow through walls and inhibits the passage of sound waves. The fine fibers also absorb some of the sound energy, mainly at higher frequencies.

Using R13 insulation is an affordable and straightforward way to add mass and damping to walls and ceilings.

This limits vibrations and impedes the transfer of noise. It performs these soundproofing functions well, especially when installed properly into cavities without any gaps or air leaks.

Why R13 Insulation Is Good For Soundproofing

There are several key reasons why R13 insulation is effective for soundproofing:

The thick density of R13 insulation blankets fitted into wall cavities greatly limits airflow between studs or joists.

Sound needs air molecules to travel through. By restricting air movement, the transmission of noises from room to room decreases substantially.

The snug fit and complete filling of cavities is vital for success here. Any gaps or compressed areas can compromise performance severely.

In addition to blocking sound via density, R13 insulation absorbs some of the sound energy. The numerous air pockets between the fine glass fibers capture the sound waves.

This material works best on higher frequency noises from sources like voices, music, television.

Lower frequencies readily pass through usually, but combining with drywall or other rigid boards addresses this weakness somewhat.

Compared to many specialty acoustical products on the market, R13 insulation offers an economical way to dampen noise.

The basic fiberglass batting has widespread availability and low cost, keeping material costs down. A DIY installation further contains labor expenses quite a bit.

This makes it a budget-friendly introductory soundproofing solution.

Simply adding more physical material into the wall cavities increases the mass and density noticeably.

This heightens dampening and sound blocking capacity substantially. Filling empty cavities with R13 insulation doubles up on improvements here.

The insulation finish also reduces structural vibrations that amplify noise nicely. Damping from the friction resists motion in the wall materials leading to less transmitted sound.

To obtain the maximum noise reduction benefits from R13 insulation, complete and proper installation is a must.

The material should expand to fill every inch of the wall cavities without any gaps or compressed areas. This eliminates paths for noise leakage or airflow almost entirely.

Trim pieces neatly bridge studs and seal insulation edges. Where needed, apply acoustic caulk for optimal air sealing. Stopping flanking around edges contains sound in rooms very effectively.

How To Maximize R13 For Noise Reduction

If planning to use R13 insulation specifically for its soundproofing abilities, it helps to combine it with other building methods and materials:

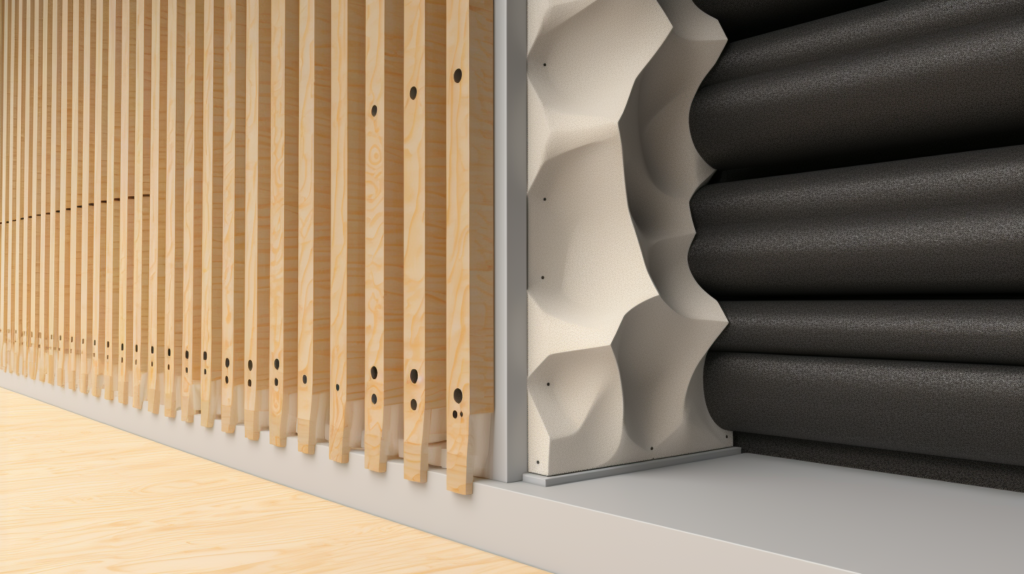

Using two layers of drywall coupled with resilient channels offers ideal enhancement to R13 insulation. The staggered wall stud configuration delinks the drywall sheets.

This prevents noise vibrations from transmitting directly across the length of wall framing.

R13 insulation fitted neatly into the cavities and sealed edges keeps sound waves from sneaking through gaps quite well. The multiple drywall layers add significant mass too for greater noise blocking.

As emphasized earlier, the compete and correct installation of R13 insulation ranks as the top priority. The installer must cut the batts accurately for flawless fit into the wall cavities.

Care must be taken around electrical boxes, wiring, and plumbing without compression occurring. No crevices or openings can remain for air leaks allowing sound through.

Trim pieces neatly bridge studs and seal insulation edges fully. Where needed, apply acoustic caulk liberally for optimal air sealing results.

While R13 insulation handles much of the noise control burden on its own, complementing it with other specialized products enhances the overall system noticeably.

Some examples include mass loaded vinyl barriers, acoustical sealant, sound damping drywall, isolation clips, etc.

These supplements address specific weaknesses like minimal low-frequency sound blocking attempts. A holistic approach utilizes the strengths of each material very efficiently.

What To Know If R13 Meets Your Soundproofing Needs

The amount of soundproofing required depends greatly on the type and volume of noise needing reduction or containment and the desired outcome.

R13 insulation delivers excellent control of mid to high-pitched interior noises like conversations, laughter, TV or music sounds seeping through walls quite well.

For ongoing loud disturbances or lower frequencies, consider upgrading insulation density or pairing with additional specialized soundproofing materials.

Testing the before and after noise levels offers the best gauge of real-world noise reduction capacities.

Conduct testing from both sides of a partition if possible while creating typical levels of noise generation.

Compare the loudness reaching the other sides with and without R13 insulation installed. This confirms if the product adequately meets current soundproofing needs quite accurately.

How To Make R13 Installation More Soundproof?

No single product blocks all noise frequencies equally. Supplementing R13 insulation with other sound dampening materials enhances overall performance noticeably:

Extra layers improve sound blocking across all frequencies substantially.

Applying sound dampening panels or multiple sheets of drywall over installed R13 insulation provides increased mass and damping tremendously.

Staggering wall attachments also help de-couple noise transfer effectively.

While R13 insulation fits tightly into place, flanking often occurs where partitions meet floors, ceilings and perpendicular walls.

Acoustical caulking seals these crevices denying noise intrusive entry points. Resilient channels further isolate the wall framing to prevent flanking weaknesses.

For problematic low frequency noises, specialized materials like mass loaded vinyl or soundboards offer a good match.

These pair well by controlling noise spectrums R13 insulation does not handle well alone generally.

Combining several complimentary products allows each one to contribute unique sound dampening strengths.

Conclusion

In conclusion, R13 insulation is an affordable and effective solution for soundproofing interiors.

When installed correctly without gaps or compression, R13 batts can significantly reduce noise transmission, especially for mid-high frequency sounds.

For problematic low frequency noise control, R13 performs best when paired with additional mass loaded materials like extra drywall or MLV barriers.

Test noise levels before and after insulation to confirm if R13 meets current soundproofing needs. Supplementing with specialized acoustical caulking, channels and clips optimizes the performance.