Is your HVAC system’s constant hum becoming an unbearable din?

Targeted soundproofing upgrades can dramatically reduce HVAC noise for a calmer home environment.

Let’s explore the most effective ways to soundproof your HVAC system equipment, ductwork, and vents.

Why Soundproof Your HVAC?

Having an HVAC system that generates excessive noise can be an aggravating issue in any home.

The underlying sounds from fans humming, air rushing through ducts, vibrations against walls and floors, and more contributes to an omnipresent din that never goes away.

This frustrating HVAC noise can make it hard to hear conversations, focus on tasks, unwind in the evenings, and even get a decent night’s sleep.

Fortunately, there are ways to gain control over the situation and create a peaceful home environment.

Implementing strategic soundproofing materials and techniques on your HVAC equipment and ductwork can significantly reduce noises for a calmer indoor space.

Let’s explore the main benefits of soundproofing an HVAC system and how it can improve your home:

Soundproofing reduces HVAC noise transfer from the mechanical equipment and ductwork into the living spaces of your home.

The goal is to dampen sound vibrations at their source before they have a chance to bother you in frequently used rooms.

Proper acoustic insulation, barriers, seals, mounts and other specialized products are very effective at blocking, absorbing and preventing noise from traveling out of the HVAC system.

Upgrading key components with sound-dampening features directs sounds back inward rather than letting loud volume radiate outward to echo through your home.

Targeted soundproofing substantially minimizes the amount of humming, rumbling and whooshing from the HVAC system that comes through supply and return vents into spaces like bedrooms, living rooms, kitchens and home offices.

This allows you to reclaim peaceful quiet in the areas you spend your time.

Soundproofing allows you to comfortably run the HVAC system whenever needed without the noise being a disturbance.

While a minor hum or whoosh from the vents may seem benign at first, it builds up over time to become an aggravating distraction.

Listening to TV shows or music while the HVAC drones in the background makes it harder to hear properly.

Carrying on conversations requires raising your voice over the HVAC sounds. Settling down to read a book or focus on work becomes frustrating when the ever-present hum makes it hard to concentrate.

And the noise certainly does not help when trying to fall asleep or return to sleep if an HVAC cycle kicks on.

Soundproofing upgrades allow you to maintain the desired temperature in your home without the aggravating side-effect of loud machinery churning in the background.

Stopping noise at the source prevents it from bothering you while you try to talk, relax, work, or sleep.

Soundproofing creates a calmer, more peaceful home environment overall. Between kitchen appliances, plumbing, neighbors, outside traffic, and other sources, our homes contain lots of excess noise pollution we did not sign up for.

The unrelenting hum of an HVAC system just adds to the chaotic mix.

By implementing sound dampening materials proactively, you can gain some control over your interior noise levels for a more relaxing vibe in your personal space.

Drowning out the HVAC din and other sounds creates a sanctuary right in your own home.

In summary, soundproofing your HVAC system provides noticeable benefits in day-to-day home life.

You should no longer have to tolerate loud, frustrating HVAC noise ruining your conversations, focus, relaxation or sleep.

The right soundproofing solutions reduce noises directly at the source for peaceful living spaces.

Soundproofing Materials

Now that we’ve covered the benefits, let’s look at the main soundproofing materials and products used by HVAC professionals to achieve significant noise reduction in ductwork and equipment.

Each material serves a role in absorbing sound vibrations or preventing their transfer from the mechanical components into rooms. Some common soundproofing materials include:

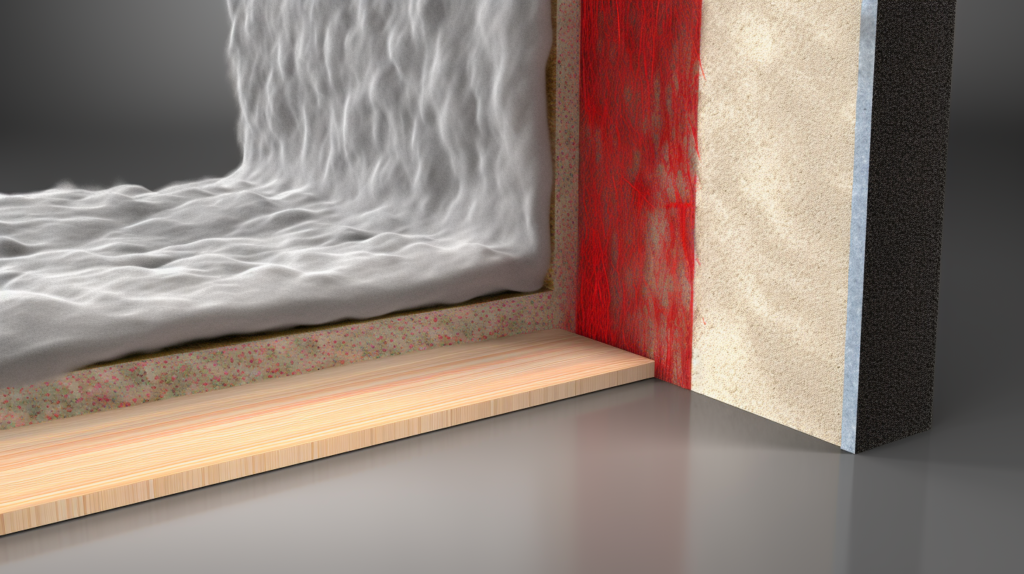

Acoustic insulation installed around all ductwork running to and from the HVAC unit. The insulation adds mass and density to limit noise passing through the barrier it creates.

Fiberglass and noise attenuation insulation wraps are commonly used to wrap ducts passing through walls, floors, and ceilings.

This adds a sound-absorbing buffer that dampens noise emanating from the metal duct walls. It contains sounds within the ductwork rather than letting them freely transmit.

The insulation also minimizes sound transfer through framing cavities around the ducts themselves. Maintaining isolation from adjacent rooms is key.

Mastic and duct sealants applied thoroughly to seal all ductwork connections and potential air leaks. Even small gaps or cracks in ductwork can allow noise to escape into wall and ceiling cavities.

Air leaks also reduce HVAC efficiency. Professionals use mastic and metal foil tape to completely seal joints, seams, elbows and connections in the ductwork.

This eliminates pathways where rushing air and related noise might otherwise radiate outward.

All spaces around supply and return vent boxes are also carefully sealed for maximum sound isolation. Stopping noise from exiting the ducts keeps it contained.

Acoustic duct liner installed on the interior of duct walls adds mass and a sound-absorbing barrier surface.

The dense fiberglass or foam material lines the inside of metal ducts to dampen noise before it can exit.

Sound waves reflecting inside the ducts lose energy as they pass through the sound-absorbing duct liner.

This reduces the volume of fan sounds and airflow noise inside the system so less transfers through. Duct liner is very effective at absorbing higher frequency sounds.

Acoustic duct connectors between the HVAC unit and main trunk ducts prevent excess noise caused by vibration transfer.

The flexible boots, sleeves, or couplings make sure vibrations from the equipment do not translate directly to the ductwork walls, creating additional noise.

Isolator connectors made of fabric, rubber, or foam act as a barrier to block this noise “bridging”.

Less vibrations reaching ducts means less sound radiated outward. Proper installation is critical for noise control.

In summary, knowledgeable HVAC technicians have access to a wide variety of proven soundproofing materials to curtail noise issues in ducts and equipment.

Tailoring a solution from quality acoustic products specifically suited to the noise problem areas will provide the best sound reduction results.

Soundproof the HVAC Unit Itself

In addition to managing noise in the ductwork running through your home, it is also important to address sound control directly at the HVAC equipment.

Stopping noise at the main machinery source is the most effective approach before it ever has a chance to travel through ducts. Some of the best ways to soundproof the actual HVAC components involve:

Applying acoustic mats, blankets or other barrier materials directly onto the HVAC system equipment that generates the most noise.

This could include air handlers, condenser pumps, furnace walls, blower units, compressor cabinets, etc.

The sound dampening material acts like a dense, heavy blanket to absorb vibrations and block sound waves from radiating outward.

These specialized acoustic blankets and mats are similar to products used in cars for noise control in the wheel wells and firewall.

Cutting sheets to fit and adhering directly to the noisiest equipment prevents noise breakout.

Building an acoustic enclosure or sound barrier around noisy HVAC machinery located outside the home, like condensers and compressors.

A well-constructed and sealed noise containment box around the unit forces sounds inward rather than letting them freely transmit to the environment.

Enclosures can be built from rigid materials like plywood, acoustic drywall, soundproofing composite panels, or even heavy flexible sound blankets.

The box must allow sufficient airflow to prevent overheating while blocking noise. Strategic ventilation openings, baffles and fans help dissipate heat buildup.

But the insulating properties keep noise contained.

Installing the HVAC system machinery on vibration dampening pads, mounts, or hangers to prevent transfer of vibrations into walls and floors that cause noise.

Just like damping in duct connectors, isolating the equipment from surfaces reduces transmitted vibrations that turn into sound.

Effective pads and mounts act as shock absorbers between the vibrating unit and the floor or wall it sits on.

Different isolator materials like dense rubber, neoprene, or spring systems help block this noise transfer.

Relocating any HVAC system machinery away from bedrooms, living rooms, offices and other spaces prone to noise disruption.

If possible based on the home layout, consider moving air handlers, furnaces, condensers, etc to a more soundproofed location farther from frequently used rooms.

Positioning equipment in closets, attics, basements, crawlspaces, or the garage can distance bothersome sounds. This complements other soundproofing methods for minimal noise impact in gathering areas.

Carefully soundproofing the HVAC equipment itself at the source addresses the core of the noise problem.

Before sound even has a chance to travel into the ventilation system ductwork, it is blocked, absorbed, and isolated.

This comprehensive approach prevents HVAC-related noise from bothering people in the quiet spaces they want to enjoy.

Soundproof Supply and Return Vents

Supply and return air vents allow HVAC noise to easily transfer from the ductwork directly into living spaces.

Any noise not stopped in the ducts or equipment will come pouring from these vents – so they are a critical final pathway to control. Some effective ways to reduce vent noise include:

Installing an acoustic lined vent box/boot where the duct connects to supply and return vents in rooms.

The sound absorbing insulation inside the vent box absorbs noise as air passes through one last time before entering the room.

This minimizes the amount of HVAC noise actually emitted into living areas. Lined vent boxes are available to retrofit existing vents or install on new ductwork branches.

Replacing any existing plastic, metal or untreated vent grilles/registers with acoustic vent grilles specifically designed to dampen noise.

These upgraded grilles use internal baffles and sound absorbing materials to dissipate noise so less transfers through the vent cover surface into rooms. The interior construction blocks and redirects sound.

Extending main duct trunk distances along indirect routes using lengthy branch ducts and acoustic elbows/bends right before reaching vent openings.

This forces air and noise to travel farther, losing sound energy around each bend before exiting.

The longer path and gradual turns better contain noise in the ducts rather than taking a direct shot into rooms. Strategic duct routing prevents noise transfer.

In addition to controlling noise at the main system level, stopping sound at the vents as it exits delivers huge sound reduction benefits.

People will no longer hear rumbling and whooshing directly from loud vents that essentially act like speakers projecting sound.

Cutting down vent noise provides the final layer of sound protection between the HVAC system and your living spaces.

Hire an HVAC Professional to Maximize Success

While a basic DIY enthusiast may be tempted to try and soundproof their HVAC system themselves to save money, this is not advised for best results.

Acoustic engineering is complex, and improper installation of soundproofing materials can render them ineffective or possibly even counterproductive.

Hiring professional HVAC technicians is highly recommended to ensure proper work and maximum noise reduction for several key reasons:

Experienced HVAC professionals can analyze your current system setup and listen to the types of noise concerns to design a customized soundproofing plan tailored to your equipment model and home layout.

Determining where problematic noises originate and transmit will inform the ideal combination of soundproofing approaches to address the issues.

Randomly adding some insulation or sealant often does not resolve the source. An expert assessment guides strategic recommendations so money is not wasted.

Technicians have access to high-quality commercial grade soundproofing materials available and the knowledge for proper installation in HVAC applications.

Certain products are specifically suited for ductwork versus equipment soundproofing for optimal performance.

Correct installation without gaps, air leaks or compression issues is crucial or the noise solution will not work right. Well-intentioned DIY mistakes can limit the effectiveness of soundproofing.

Experienced professionals can identify the specific weakest links contributing the most to noise transmission in your system.

Isolating underperforming sections or problem equipment allows soundproofing efforts to focus there first.

Stopping noise at the source requires an expert eye to spot ducts, vents or machines causing issues. Amateurs may have difficulty pinpointing origin points.

In summary, while simple soundproofing projects are possible as a homeowner, an HVAC system involves intricate equipment and ductwork running through walls and ceilings.

Acoustic engineering principles and access to robust commercial soundproofing products gives technicians the knowledge and tools to implement solutions that actually work.

An investment in a professionally soundproofed HVAC system will pay off in peaceful living spaces.

Conclusion

If an excessively noisy HVAC system is creating an unpleasant living environment in your home, know that help is available.

Implementing soundproofing materials and techniques can dramatically reduce unwanted HVAC noise from equipment, ducts and vents.

Focus first on stopping noise at the source using acoustic blankets around units, vibration isolation mounts, and professional sealing of all air gaps in the system.

Then absorb any remaining sounds before they exit vents into rooms using lined ducts and vent boxes.

With some methodical soundproofing upgrades performed by experienced technicians, you can once again run your HVAC system whenever needed without the aggravating din of loud equipment and airflow disrupting your conversations, concentration, relaxation or sleep.

Your home can become a peaceful sanctuary that feels worlds away from the humming and whooshing of a heating and cooling system hard at work.