Do you struggle to hear critical instructions over the constant din of machinery in your metal industrial building?

Implementing targeted soundproofing materials and modifications can effectively reduce disruptive noise for better function.

Let’s dive into optimal methods for soundproofing metal building interiors.

Why Soundproofing Is Important For Metal Buildings

Metal buildings like warehouses and factories often have thin metal wall and roof construction that allows exterior noises from heavy machinery, vehicles, rain, and voices to easily intrude inside.

These noises then reverberate loudly within the large open interiors. This excessive noise can negatively impact worker focus, productivity, fatigue, safety, communication, and morale.

Implementing proper soundproofing modifications helps reduce interior noise levels to comply with legal decibel limits from local noise ordinances.

There are several benefits to soundproofing metal buildings:

Improved Focus – Excessive noise is physically and mentally distracting for workers. Loud disruptions break concentration, leading to mistakes and accidents.

By reducing noise to acceptable levels, employees can stay focused for longer periods with fewer interruptions. This allows for greater accuracy and quality of work.

Increased Productivity – Studies show prolonged exposure to loud noise from machinery, vehicles, voices, etc can reduce productivity in industrial settings.

With excessive noise removed through soundproofing, workers can achieve greater output and efficiency.

Reduced Fatigue – Working in a noisy industrial environment leads to headaches, irritability, stress and exhaustion over a full shift from noise bombardment.

By lowering the noise pollution through soundproofing, occupants experience less auditory fatigue.

Enhanced Safety – Loud noise can mask important warnings, announcements, equipment malfunctions or moving vehicle sounds.

This leads to safety incidents. Soundproofing allows workers to clearly hear critical noises to prevent accidents.

Improved Communication – Excessive noise makes normal conversation very difficult within metal buildings.

Employees must shout to be heard. Soundproofing reduces ambient noise levels so that speech, directives, and announcements can be clearly interpreted.

Better Morale – Prolonged exposure to excessive noise causes tension, anger and anxiety in the workplace.

A calmer, quieter environment from soundproofing creates happier, more relaxed employees with improved morale.

Legal Compliance – Soundproofing prevents noise ordinance violations that can lead to heavy fines and legal problems for building owners and companies.

Keeping indoor sound levels within local regulations is essential.

Key Soundproofing Materials

There are several types of materials that can help reduce noise within metal buildings:

Sound Absorption Insulation – Materials like fiberglass or mineral wool insulation work by absorbing noise rather than reflecting it.

The porous fibrous insulation, installed in wall and ceiling cavities, traps sound waves and vibrations. This minimizes reverberation for a quieter interior.

Resilient Channels – Horizontal metal channels installed between wall framing and drywall decouple the two surfaces.

This isolation prevents noise and vibration from transmitting through the metal studs into drywall. Resilient channels absorb vibration energy.

Acoustic Caulk – Specialized caulking and sealants block sound leakage through cracks, openings and joints.

Caulking seals all gaps around wall penetrations, doors, windows, and partitions. This containment stops flanking noise between rooms.

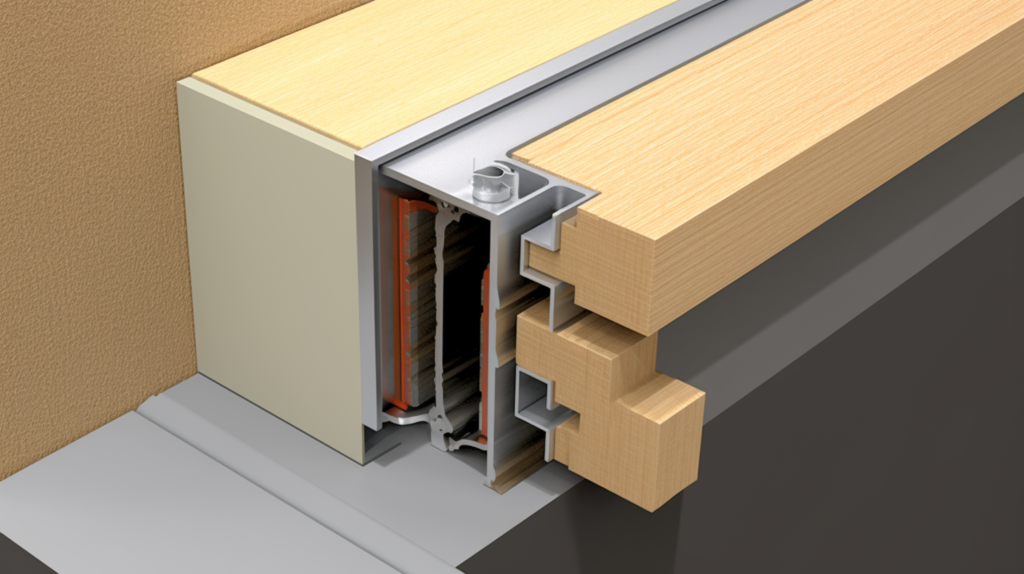

Weatherstripping – High density weatherstripping installed around doors and windows seals the small openings surrounding frames to prevent sound transmission through.

Effective materials include brush piles, vinyl dams, and door bottom sweeps.

Soundproofing Walls

Walls allow significant noise intrusion and should be a priority. Metal wall panels offer no meaningful sound isolation.

Recommended methods to improve wall acoustic isolation include:

Constructing a second interior wall against existing girts by installing new steel studs. The double wall creates an air gap cavity.

Packing high-density sound absorption insulation into the wall cavity. Insulation materials like mineral wool work best to absorb noise reverberation within the cavity.

Applying resilient channels horizontally to wall studs before installing drywall decouples the surfaces, preventing vibration transfer through framing.

Using multiple layers of drywall screwed into channels provides mass which reflects noise. Stagger seams between layers and seal with acoustical caulk.

The double wall method creates an overall thicker partition with damped cavities for maximum noise containment.

Soundproofing Ceilings

Ceilings allow excessive noise into occupied rooms from reverberation within the open roof structure and require treatment. Recommended steps include:

Adding new ceiling joists below existing roof decking to create a dropped ceiling with an isolated cavity.

Packing sound absorbing insulation above dropped ceiling between joists to dampen reverberation from the roof deck above.

Installing resilient channels on ceiling joists before affixing drywall decouples roof from drywall. This prevents vibration transmission.

Using multiple drywall layers screwed into channels provides mass to reflect noise. Seal seams with acoustical caulk for air tightness.

Penetrations from lights, vents etc. must be caulked thoroughly to contain noise. The floating ceiling reduces reverberation.

Soundproofing Doors

Doors constantly allow noise to flank between rooms. To improve door sound isolation:

Install solid core wood doors with insulating cores and integral sound seals. Solid doors prevent noise transmission better than hollow lightweight doors.

Affix continuous, compressible weatherstripping around entire door perimeter – on jambs, head, and threshold for an airtight seal. High density vinyl, brush, or sweep seals work best.

Door bottoms sweeps seal the gap at thresholds as doors close. Automatic door bottoms provide the tightest acoustical seal.

Quality weatherstripping ensures the door seals tightly to the jambs with no gaps that compromise acoustics.

Soundproofing Windows

Windows allow exterior noise to easily enter buildings. For improved window sound isolation:

Thicker glass panes made from layered laminated glass provide better noise reduction than standard thin windows. 1/4″ or 1/2″ thick glass substantially blocks more sound.

If replacing glass is not feasible, install a second set of interior window panels sealed airtight around the perimeter with acoustical caulk. The air gap between window layers increases insulation.

Ensure window installation includes complete sealing around the frame and shims to prevent sound flanking around the glass. Backer rod combined with caulk seals openings.

Smaller sized windows limit the surface area where sound transmission occurs. Position higher on walls away from noise sources.

Containing Mechanical Noise

Major interior noise sources require isolation or containment measures:

Mounting noisy HVAC units or other vibrating equipment on neoprene isolators prevents structure-borne vibration transfer into occupied rooms. Proper isolator stiffness selection is key.

Building enclosures around particularly loud equipment, lined internally with MLV barriers or acoustic foam, contains the noise. Fully seal doors and access points to prevent leakage.

For heavy duty applications, constructing a room-within-a-room on floating floors with de-coupled double drywall walls maximizes containment. Position the room away from occupied areas.

Adding industrial grade silencers, baffles, acoustic duct liner, or mufflers to air vents and ductwork reduces reverberation from air handling systems.

Applying these types of noise control materials and techniques can effectively reduce interior sound levels for compliance with local noise regulations, resulting in a quieter and calmer environment for workers.

Conclusion

Properly soundproofing a metal building requires strategic use of noise absorbing materials, isolation techniques, and containment solutions.

By focusing efforts on soundproofing walls, ceilings, doors, windows, and interior noise sources, industrial facilities can achieve compliance with local noise regulations.

This results in a calmer, quieter workspace that enhances communication, focus, productivity, and employee wellbeing.

With diligent acoustic treatment, metal buildings can provide suitable environments for occupational success.