If you’re researching soundproofing solutions, you may be wondering – is polystyrene foam effective?

While polystyrene has some acoustic uses, it is a poor soundproofing material that allows noise to freely transmit through it.

Let’s dive in to understand why polystyrene lacks the physical properties needed for proper noise blocking and which materials work better.

What is Polystyrene?

Polystyrene is a synthetic plastic polymer material made from the monomer styrene. It is frequently used to produce rigid foam products like disposable cups, packaging materials, insulation boards, and more.

The polystyrene foam is very lightweight yet rigid, with a porous cellular structure. This closed-cell foam is water-resistant and an excellent insulator.

Common applications of polystyrene foam include cushioning for packaging fragile items, insulation in walls and roofs, food containers, floating devices for docks, and craft materials.

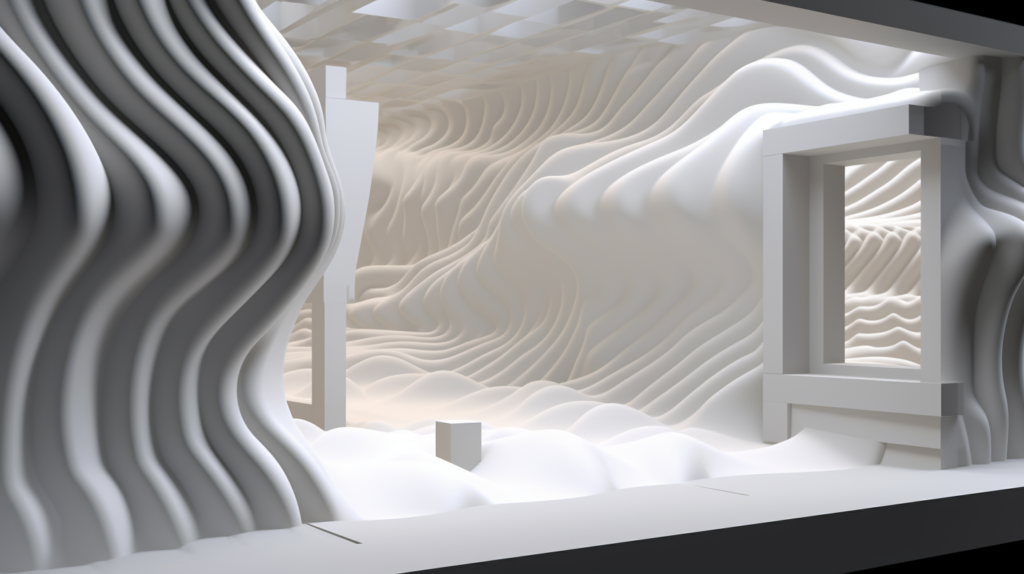

The white foam is also often used as the base material for architectural models due to its carve-ability. Overall, polystyrene is valued for its lightweight, stiff, and insulating properties across many industries.

Is Polystyrene Good for Soundproofing?

No, polystyrene is not good for soundproofing. It lacks the mass and density required to effectively block sound transmission.

The porous and lightweight foam structure allows sound waves to freely pass through polystyrene. This material is better suited for acoustic treatment to reduce echoes and reverberation in a room.

But polystyrene does not have the physical properties needed to prevent exterior noise from penetrating through a structure.

To summarize, polystyrene should not be relied upon as a soundproofing material. Its characteristics make it ineffective for noise blocking.

The very properties that make polystyrene useful for insulation and packaging do not translate well to soundproofing.

The low-density foam has an open cellular structure, which allows noise to travel through the pores. Sound waves can even cause the polystyrene to vibrate like a membrane.

This lack of mass and stiffness means polystyrene panels or foam sheets do little to stop sound transmission.

Any small gaps, cracks, or thin spots in the material further decrease its already limited noise blocking capacity.

While polystyrene foam can dampen echoes and reverberation within a room, this acoustic treatment is different from preventing exterior sounds from entering.

Materials with density and mass are required to impede sound waves and obstruct their path. Polystyrene does not have these attributes, nor does it isolate vibration or block airborne noise.

Therefore, it should not play a primary role in soundproofing strategies.

Why is Polystyrene Not Good for Soundproofing?

There are several key reasons why polystyrene foam is ineffective for soundproofing purposes:

Lightweight and Low Density

Polystyrene is an extremely lightweight foam material. It does not have enough mass or density to impede sound wave transmission.

Heavy, dense materials are better at obstructing noise paths and damping vibrations. The minimal mass and porous nature of polystyrene allow it to compress and flex readily under sound pressure.

This does not effectively stop noise from passing through the material.

Prone to Damage and Gaps

The lightweight foam is easily damaged, cracked, or indented. Any small gaps or inconsistencies in the polystyrene allow sound to leak through.

It can also sag or deform over time when installed on walls or ceilings. These dents, cracks, and uneven surfaces permit noise transmission despite the polystyrene panels.

Proper soundproofing requires solid, seamless materials.

Flammable Material

Polystyrene is highly flammable, especially compared to many other insulating and soundproofing products. This poses a serious fire hazard if the foam is exposed to high heat sources.

Building codes restrict certain flammable materials due to safety risks. This may limit where and how polystyrene can be used.

Off-Gassing Issues

The polystyrene foam material emits VOCs, or volatile organic compounds as it cures and ages.

Exposure to these off-gassed chemicals from the foam can reduce indoor air quality and irritate lungs. Proper ventilation is required, but this also undermines soundproofing efforts.

Ineffective Noise Blocking

In summary, the biggest problem with using polystyrene for soundproofing is that it simply does not block noise well.

The porous foam allows sound waves, vibrations, and reverberations to pass through. Small imperfections compound this issue.

Denser materials rated for high noise reduction are necessary to achieve quality soundproofing.

Effective Alternatives To Polystyrene

In contrast to polystyrene foam, quality soundproofing relies on materials with density, mass, rigidity, and impermeability. Materials commonly used for effective noise blocking include:

Mass Loaded Vinyl

Mass loaded vinyl is a dense, heavyweight vinyl material layered with barium salts or other mineral fillers. This adds mass to dampen vibrations from noise.

The limp vinyl also helps decouple wall layers. Mass loaded vinyl averaging 1 lb/sq ft is ideal for optimal soundproofing and easy installation.

Acoustical Drywall

Specialized drywall, like QuietRock, absorbs and blocks noise through sheets laminated with viscoelastic damping compounds.

The limp mass layer reduces vibration transmission. Dense glass fibers also increase sound absorption. Double or triple layers of acoustical drywall on staggered studs optimize soundproofing.

Green Glue Noise proofing Compound

Green glue is a viscoelastic polymer material used between drywall or panel layers. The damping compound turns noise energy into low level heat energy.

This improves sound isolation by sealing panels and damping vibration. It is highly effective when layered between panels.

Acoustic Caulk

Specialized acoustic caulks and sealants block noise leakage through cracks and gaps in the structure. Flexible sealing compounds prevent sound transmission in areas vinyl or drywall sheets can’t cover.

Caulking window frames, electrical outlets, vents, etc. seals the envelope.

Insulation

Sound-absorbing insulation like rock wool, cellulose or fiberglass minimizes reverberation and dissipates noise within wall & ceiling cavities.

Insulation combined with drywall, plywood, vinyl and other mass-loaded materials enhances overall sound isolation.

Proper soundproofing requires a layered system of dense, massive materials to obstruct sound pathways and dampen vibrations.

Relying solely on low-density polystyrene foam does not provide the necessary composition for effective noise blocking.

Soundproofing Alternatives That Are Very Effective

While polystyrene foam has minimal benefits, many better soundproofing solutions exist:

Double Stud Walls with Staggered Studs

Double frame walls with staggered studs and insulation minimize noise transfer by isolating and decoupling wall layers. Staggered studs prevent direct contact or vibration transmission between frames. Sound-absorbing insulation dampens noise. Drywall or plywood sheathing resists noise penetration.

Sound Transmission Class (STC) Rated Materials

Specialized noise blocking drywall, sealants, doors, and insulation carry STC ratings indicating their acoustic isolation performance.

Materials rated at least STC 45 are preferable, with higher being better. STC-rated assemblies block more sound than plain drywall and framing.

Noise Isolation Clips and Channels

Metal clips decouple wall layers by separating drywall sheets from studs or joists. Resilient channels positioned horizontally further dissipate noise vibration and energy.

This prevents noise flanking up through structural elements. Isolation clips work best with multiple drywall layers.

Acoustic Room-Within-Room Constructions

Freestanding new interior walls decoupled from exterior load-bearing walls provide superior sound isolation. Multiple layers absorb and obstruct noise paths.

Floating floors also help separate and isolate rooms. High performance but complex and expensive.

Sound Masking Systems

Sound masking uses electronic systems to emit gentle background noise and distract from intruding noises. The uniform ambient noise masks unwanted sounds and speech privacy issues.

It is more natural than actively canceling sounds and practical for large implementations.

Numerous materials and construction techniques offer economical to elaborate soundproofing options.

Polystyrene can play a small role but does not substitute for purpose-built noise blocking products and methods.

Prioritizing density, mass, isolation, and absorption delivers genuinely effective acoustic isolation.

Conclusion

In summary, polystyrene foam does not provide effective soundproofing. It lacks the density and mass required to block exterior noise transmission.

The lightweight, porous material allows sound to pass through it rather than impeding sound pathways. Small imperfections further degrade limited noise isolation capacity.

Polystyrene has minor acoustic benefits for damping echoes and vibrations. But it should only supplement other robust sound blocking materials and methods.

True acoustic isolation requires heavy, dense, stiff materials rated for high noise reduction.

Purpose-built soundproofing products and constructions outperform polystyrene. Focusing on mass, density, isolation, absorption and impermeability yields superior noise blocking results.

When designing soundproof spaces, rely on proven materials like mass loaded vinyl, acoustical drywall, and isolation clips.

Polystyrene foam alone has minimal soundproofing ability, so utilize appropriate sound-blocking alternatives.