Driving used to be a noisy and fatiguing experience. But what if you could transform your car into a sanctuary of silence?

Soundproofing your car doors properly is the most effective acoustic upgrade you can make.

In this complete guide, we’ll cover why doors matter, walk through the soundproofing process, and reveal pro techniques for premium noise blocking.

Let’s dive in to creating acoustic bliss on the road.

Why Soundproof Your Doors?

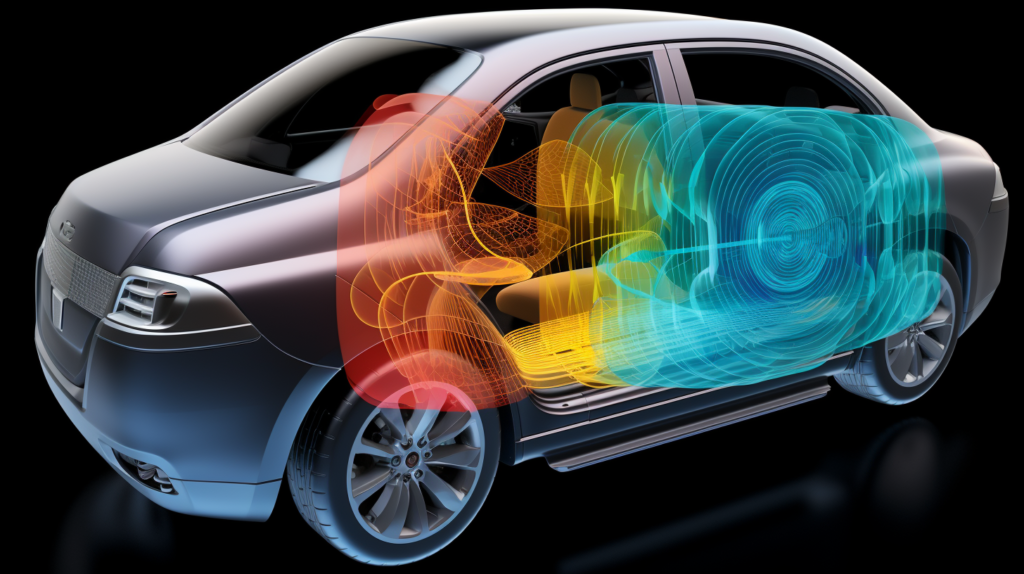

Let’s first examine why soundproofing your doors is one of the best ways to improve the interior acoustic environment. Door panels tend to be thin and lightly reinforced, causing the large sheet metal surface area to resonate easily.

Vibrating metal distorts music and road noise easily permeates the weak barrier. Treating your doors isolates sound waves, absorbs echo and reverb, and blocks exterior noise from passing through.

Well-damped doors prevent cavity resonance and panel vibrations for distortion-free music. The result is significantly cleaner audio quality and reduced cabin noise.

What Are The Materials Needed To Soundproof A Car?

Achieving optimal acoustic isolation requires using the right materials in each part of the door. Here we will overview the key products needed:

Sound Deadening Mats

The first component in soundproofing doors is a sound deadening mat such as Dynamat. This specialty vinyl mat contains a layer of butyl or asphalt sandwiched between aluminum foil.

When adhered to the door skin, the mat adds mass to dampen vibration while preventing panel resonances. The material improves stiffness and dampens noise through its composite layers.

Covering 60% of outer skin and 40% of inner skin is recommended.

Closed Cell Foam

In addition to damping the door skin itself, you need closed cell foam such as OverKill Pro for the door cavity. Closed cell foam is a rigid insulation that absorbs sound rather than transmitting it.

Lining the inner cavity with this foam smothers echoes and resonance inside the empty space. This prevents any reverberations from distorting the audio quality.

Closed cell foam is a must-have for clean, clear music.

Mass Loaded Vinyl

For optimal noise blocking, apply mass loaded vinyl (MLV) such as Luxury Liner Pro over the sound mats. MLV contains dense, weighted materials that provide mass to impede noise transmission.

The peel-and-stick vinyl sheets create an impermeable noise barrier across the door skins. MLV is the best option for preventing exterior road noise from entering the cabin space.

Recommended Brands

Some top-rated brands for soundproofing products include Dynamat, HushMat, Kilmat, SoundSkin, SoundQubed, and Stinger for sound deadening mats. Noico, GTMat, KoniKore, Second Skin, and Silent Coat are popular for closed cell foam.

For mass loaded vinyl, try Luxury Liner Pro, ResoNix, Soundproof Cow, AcousticSheep, or DB3.

Adhesives & Preparation Products

You will also need adhesive, cleaner, applicators, and tools. Use butyl or spray adhesives to install mats and MLV.

Plastic cleaner preps the door panels before installing anything. Foam applicators make smoother installations. Utility knives, snips, squeegees help customize materials.

How To Soundproof A Car Door?

Soundproofing your car doors is a multi-step process but following some key actions will lead to success. Now let’s review each of these important steps in detail.

Step 1: Remove Door Panel

The full interior door panel must be removed to access the door. Locate and remove any trim screws or clips fastening the panel using proper hand tools.

Detach the panel from the handle and latch linkages. Remove components like the window cranks. Extract the entire panel slowly and carefully to avoid cracking.

Consult factory service manuals for your specific vehicle’s door panel removal. Lay the panel aside safely until it is time for reinstallation.

Step 2: Clean Surfaces Thoroughly

With the panel off, thoroughly clean the outer and inner door skins where you will apply soundproofing materials. Use a grease and wax remover specially formulated for auto surfaces.

Wipe down the inner and outer skins completely using a clean, lint-free rag until zero residue remains. Proper surface cleaning allows the soundproofing materials to adhere tightly.

Step 3: Apply Sound Deadening Mat

With pristine door surfaces, mapping out mat placement is next. For the outer skin, cover around 60% of the area in 1 foot square sections.

Focus on large open sections prone to vibration rather than small stiff areas. For the inner skin, cover around 40% area unless highly reinforced. Use a roller and utility knife to cut neat sections of Dynamat-type mat to fit each area.

One by one, peel off the backing and firmly press the adhesive mat to the metal. Smooth and rub each section as you affix it to ensure a robust bond.

Step 4: Install Closed Cell Foam

Measure the door cavity interior and cut pieces of rigid closed cell foam to fit snugly inside. Leave clearance gaps for window tracks and other components.

Apply foam pieces to cover most of the cavity, absorbing sound and preventing resonance inside the empty space. Back the foam pieces with adhesive or secure mechanically when possible.

The foam dampens echoes and reverb to improve music clarity.

Step 5: Reinstall Door Components

Before sealing up the door, properly reposition any electrical, mechanical, or structural components previously removed. Consult factory diagrams to verify locations.

Make sure lock rods, window regulators, wiring, and metal braces are remounted correctly. Verify normal operation of all moving parts like windows and locks before proceeding.

Step 6: Reattach Door Panel

Carefully reinstall the door panel onto the door over the installed soundproofing materials. Align any attachment clips and slide the panel back into place.

Reconnect panel linkages to handles and latches. Tighten any fastener screws and press the perimeter on firmly to seat the panel.

Verify full functionality of doors locks, windows, and electronic components with the panel reattached.

Step 7: Treat All Doors

Perform the full soundproofing process on all four doors for complete acoustic isolation. Consistency across doors is critical.

Prioritize the front doors first since they likely contain your speakers, then repeat the same process for rear doors. Equal treatment across doors optimizes noise blocking and audio clarity throughout the cabin interior.

Step 8: Install Mass Loaded Vinyl

To further improve noise blocking, particularly for road noise, install 1/8″ mass loaded vinyl over the sound mats. Measure each door and custom cut MLV sheets to overlap and cover the entire outer skin surface.

Remove adhesive backing and carefully apply the MLV from top to bottom. Use a roller to form a tight bond and eliminate air bubbles between layers. The heavy vinyl barrier seals noise out.

Step 9: Performance Testing

Evaluate the acoustic improvements after your extensive door soundproofing process. Play music loudly and listen closely for reduced distortion and crisper clarity compared to untreated doors.

Also, have someone drive while you listen for external noise permeating into the cabin, which should be notably reduced. Check for any buzzes or rattles that may still need fixing.

Overall, the treatments should provide tangible sound quality and noise blocking improvements.

Advanced Installation Tips

Achieving truly professional-grade acoustic isolation requires using some advanced installation tactics. First, you can apply butyl-based caulk between all layers of materials for 100% adhesion.

The caulk seals the perimeter of each layer to prevent air gaps and noise leakage. Next, lining the inner plastic door speaker cavities with foam dampens sound within the enclosure.

For the mass loaded vinyl application, adhere the sheets with a pressure sensitive sheet adhesive rather than liquid glue. This allows the vinyl to bond tightly in a uniform manner across the entire surface.

Treating the inner door cavity itself like a speaker enclosure optimizes its acoustic properties. Filling hollow sections and voids within the door with expanding insulation foam prevents noise intrusion into these areas.

All MLV sheet edges should be carefully sealed with aluminum tape to create an impermeable vinyl barrier. Finally, for maximum noise protection, plastic vapor barriers inside doors can be lined with a layer of MLV prior to installation.

These advanced installation practices ensure the door cavity is completely sealed with no gaps or openings through which noise can enter. Follow these professional tips for the highest quality acoustic isolation and noise elimination in your doors.

Conclusion

Soundproofing your car doors is one of the highest value acoustic upgrades you can make. Following this extensive guide will give you the knowledge and process for maximum noise blocking and premium sound.

Properly damping panel vibrations, absorbing inner cavity echo, and establishing noise barriers significantly reduces distortion while creating a noticeably quieter cabin.

While this level of treatment requires diligence, the joys of lifelike music and peaceful driving are well worth it.

Use these techniques for superior car audio acoustics.