Is your recording studio window letting noise disrupt golden takes and ruin mixes? Tempered glass may seem like a sturdy sound barrier, but its fatal flaw leaves your audio vulnerable.

Laminated glass beats tempered alternatives for studio-grade soundproofing thanks to damping layers which isolate issues tempered glass cannot handle alone at sustainable cost.

Let’s examine essential differences in glass materials and ideal combinations to permanently protect production audio quality without regrets down the line.

What is Tempered Glass?

Tempered glass, also referred to as toughened glass.

Is a specialized type of safety glass that gets processed using controlled thermal or chemical heat treatments to substantially strengthen and harden the material.

Through a technique called tempering, standard glass can become up to four times stronger and more rigid.

The production process sees float soda lime glass panels cut to size first before entering a tempering furnace and getting heated to over 700 degrees Celsius.

Upon reaching a consistent temperature saturation point throughout, jets of cold or ambient air then blast against the hot glass on both sides causing sudden rapid cooling.

This steep temperature gradient from surfaces to core sets up balanced internal stresses, putting exterior layers into compression while interior sections pull inwards under tension.

The tempering technique thereby increases overall glass hardness and impact resistance.

When eventually fractured due to typical scratches or applied forces, properly tempered glass breaks or shatters safely into small blunt granular pieces rather than long razor-sharp jagged shards which can severely injure people.

This makes the glass ideal for safety and security demanding contexts.

Builders commonly utilize tempered glass when human impact protection and strength becomes a priority.

For example, essentially all vehicle windshields and side windows get made from tempered glass to prevent serious lacerations during collisions.

Tempered panels also frequently appear in entrance doors, skylights, building facades, staircase railings, furniture surfaces and shower enclosure partitions where people risk falling against exposed sheets.

The safety enhancement remains the most noteworthy benefit over standard float glass besides the structural boost.

Is Tempered Glass Good for Soundproofing?

The increased rigidity and density arising from the tempering manufacturing process enables tempered glass to demonstrate reasonably good sound dampening.

Acoustic isolation capacities when implemented as a noise barrier material in certain contexts, especially when dealing with lower audible frequency ranges.

In controlled laboratory tests, tempered glass consistently achieves higher Sound Transmission Class (STC).

Outdoor-Indoor Transmission Class (OITC) ratings over comparative thickness standard float glass samples – two quantitative metrics which help determine the noise blocking effectiveness of any building materials including varieties of glass.

This infers superior damping traits related to the compressed outer tempered layers interacting with sound waves.

However, any acoustical benefits get severely hampered by the unchanged internal fragility still inherent with the product.

Tempered glass remains prone to fracturing, shattering or cracking apart entirely when subjected to any significantly sudden hard blunt impacts or abnormal applied loads above tolerances

An almost certainty around recording studios where musicians transport heavy delicate equipment daily near windows and doors.

The rigid glass itself cannot flex, stretch, dent or compress gradually like wood, plastic or drywall sheets when exposed to stresses which exceed the compressed outer shell strength thresholds.

This makes tempered glass windows risky propositions for spaces likely experiencing frequent kinetic accidents or vibration contact.

The entire glass partition could spontaneously collapse into shards with even the slightest structural damage or scratch breaching layers.

Plummeting fragments also impose major injury hazards for room occupants underneath.

While the breakage mechanism of tempered glass does yield safer blunt granules, the immediate shatter explosion still presents a dangerous, disruptive, destructive event.

Considering these downsides related to brittleness and spontaneous fracture potential, architects and acousticians rarely recommend using tempered glass.

Products alone specifically for dedicated soundproofing applications like recording studio windows which demand durable permanent transparency without compromise.

Other available transparent building materials provide similar or superior noise dampening properties without heightening the risk for sudden failures.

What Is A Better Alternative Glass For Soundproofing?

For professional recording studio and discerning audiophile listening room window applications where maintaining permanent visibility and reliable acoustic isolation remains paramount, architects generally always specify laminated glass over any variety of tempered glass.

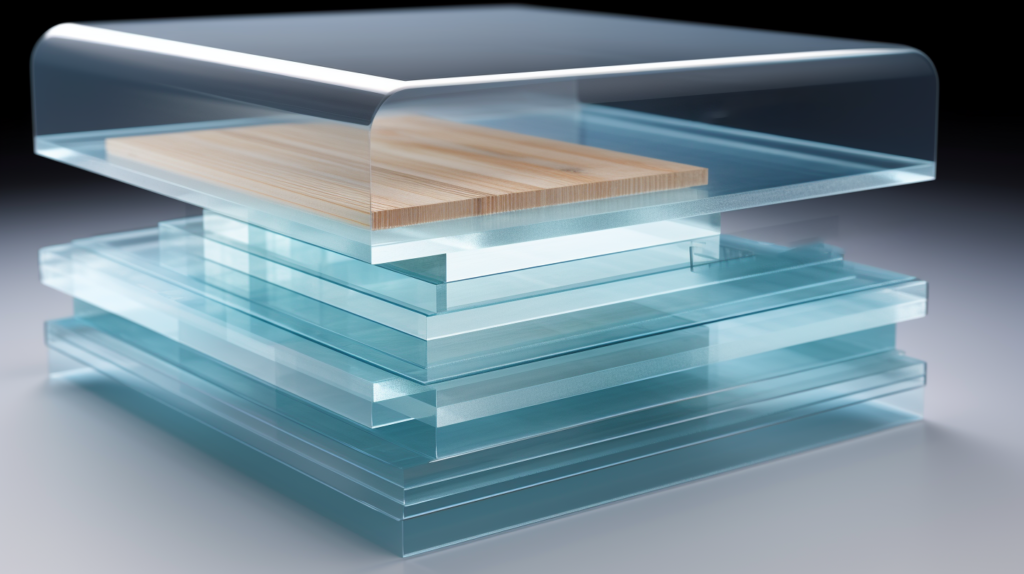

Laminated glass comprises two or more sheets of regular annealed float glass permanently bonded.

Fused together into a coherent composite using specialized acoustic barrier polymer interlayers made from viscoelastic plastic materials like polyvinyl butyral (PVB), ethylene-vinyl acetate (EVA)

Thermoplastic polyurethane (TPU), or specialized ionoplast compounds.

These tear-resistant flexible plastic interlayers act as bonding agents keeping fractured laminated glass panels adhered together even when fully cracked or broken.

This prevents dangerous shattering collapses while still facilitating emergency ingress or escape if required.

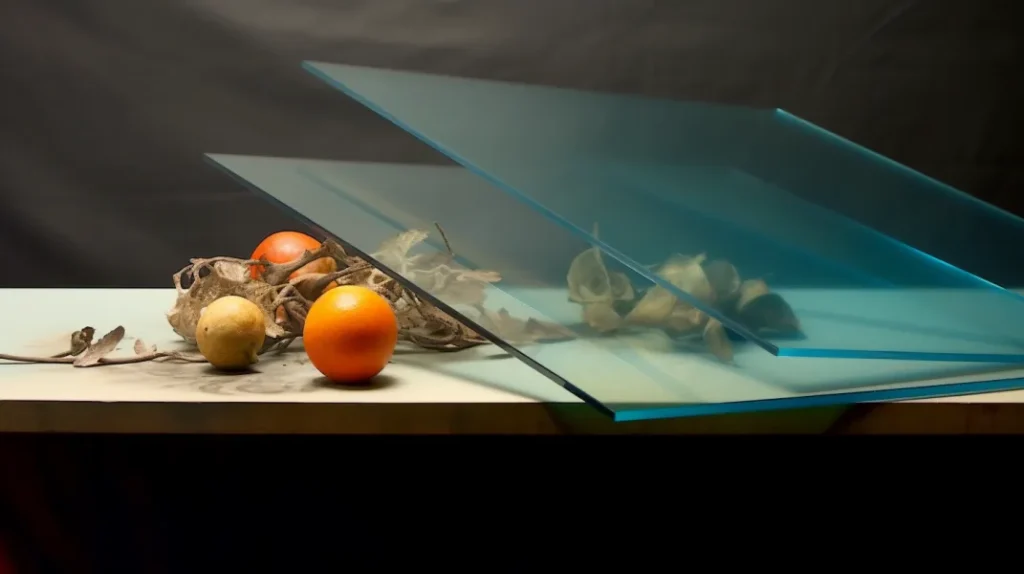

From an acoustical isolation standpoint, introducing the elastomer damping membrane interlayer also makes laminated glass superior for soundproofing over regular monolithic tempered and untempered float glass pane options.

Attached performance certification data demonstrates how laminated constructions readily outblock outside noise infiltrating working studios and listening sanctums compared to traditional inorganic

Single pane windows alone when dealing with common disruptive occupations like nearby gardening tools or passing trains.

Advanced acoustic laminates with customized interlayers focused specifically towards targeted frequency noise cancellation now even achieve precision tuned absorptiona

Making laminated glass constructions the commercial acoustic isolation gold standard within recording studio fields where perfectionist standards rule.

The Best Alternative Glass For Soundproofing

While laminated glass alone often provides sufficient soundproofing for media spaces, some studios employ an optimal tempered glass + laminate glass double glazing configuration for their windows.

This combines the strengths of both glass types to create an enhanced noise barrier assembly optimized for acoustic isolation and impact resistance.

The outer pane utilises toughened glass to flex less under wind loads and withstand hail or falling tree debris.

The inner laminate sheet then blocks the passage of noise waves and imparts additional damping. The dry air cavity gap between them further improves acoustic separation.

Sound gets trapped and decays inside this insulating void. Expert media room builders generally recommend a high performance 3/8 inch tempered glass outer pane paired with a 1/2 inch or thicker laminated inner pane.

This balances impact protection and vibration damping depth for noticeably better interior calmness.

The composite assembly outclasses most single glass windows across key indicators like STC, RW and C values.

Correct perimeter sealing and angled window sill overlaps also help minimize acoustic leakage shortfalls around the edges.

What About Basic Float Glass or Plexi Glass?

Average consumers debating whether everyday annealed basic soda lime float glass windows might reasonably temper external noise issues for small DIY home studios.

On tight budgets or amateur music practice spaces may justifiably feel attracted to the substantial upfront cost savings over acoustic laminate and tempered glass products when scoping options.

However, from an objective scientific perspective examining pure functionality, single pane basic float glass performs rather poorly.

As a dedicated sound barrier without almost impractically thick and heavy elements integrated to compensate for innate deficiencies.

When striving towards professional studio grade multi-track recording quality satisfying commercial release standards.

Skip float glass unless willing to overhaul fundamental floorplans and load bearing constructions drastically

To facilitate enormous 3 inch thick massive individual panes in double or triple window configurations necessary for merely mediocre isolation.

Compared next to laminated and tempered glass on performance noise attenuation, overwhelming thickness would be required.

Thus making integration dubious beyond niche contexts like lighthouse beam enclosures.

Realistically, amateur level interest would become the only rational application scenario where singles pane float glass windows might provide “good enough” acoustic separation without breaking construction budgets.

However, once sequentially layering enough panels and bulk thickness to match a proper soundproof window design equivalent, the associated expenditures swell beyond reason.

For professional spaces, acoustic laminated glass sells itself ten times over on noise blocking figures alone even before factoring structural and replacement advantages into cost benefit break-even analysis.

Only hobbyists should consider basic annealed float glass for its friendly price accessibility. Serious engineers need consistent clean recordings.

What To Look Out Building Out A Soundproofing Window?

When designing and building sovereign background noise insulation into studios via glass windows, remember to holistically assess and address these key considerations:

- Frame Components – Steel and fiberglass frames improve acoustic isolation versus aluminum. Allow for larger glass panes and triple glazing.

- Frequency Attenuation – Block lower frequencies for precision. Assess Rw and Ctr performance metrics.

- Duct & Edge Sealing – Prevent flanking noise paths around glass panels. Compressible tapes work.

- Pane Coupling – Smaller coupling width improves low frequency absorption.

- Glass Type Factor – Combinations of glass types enhance noise blocking.

- Isolation Panels – Supplement windows with additional mass loaded noise barriers.

- Testing – Always evaluate installed windows using sound transmission testing.

Investing in appropriately specified glass window solutions tailored to the recording environment stands crucial for quality sound reproduction and creative fidelity.

Do not cut costs implementing subpar acoustic glazing products without verifying noise isolation efficacy through reliable measurement processes.

This helps architects, acousticians and audio engineers reduce sonic distractions plus ambient irregularities artists must contend during performances, tracking and mixing activities.

Treat sound integrity as the priority design principle when conceiving glass focused recording and listening space plans.

Conclusion

In conclusion, while tempered glass alone provides reasonable sound insulation, its fragility makes laminated glass a far superior choice for soundproofing studio windows.

The optimal construction pairs durable external tempered glass with a thicker internal acoustic laminated pane, leveraging the strengths of both materials.

This balanced assembly blocks noise infiltration through high STC ratings, impact resistance and reliable acoustic integrity for decades.

Critical attributes in professional recording environments.

Architectural teams are advised to specify certified soundproof windows using laboratory test data as guidance when designing spaces demanding unbroken audio fidelity.