Does MLV soundproofing actually work to reduce noise in your home or office? With all the soundproofing products available, it can be confusing to know what really blocks noise effectively.

While mass loaded vinyl (MLV) can aid certain soundproofing applications, it has major limitations depending on how it is used.

MLV membranes excel at absorbing footfall and impact noise when properly installed under flooring. However, MLV falls short for wall and ceiling soundproofing unless combined with other materials in a multilayer assembly.

Now that we’ve outlined the promises and pitfalls of MLV, let’s dive in to understand exactly how, when, and where to use mass-loaded vinyl for optimal noise reduction.

What is MLV?

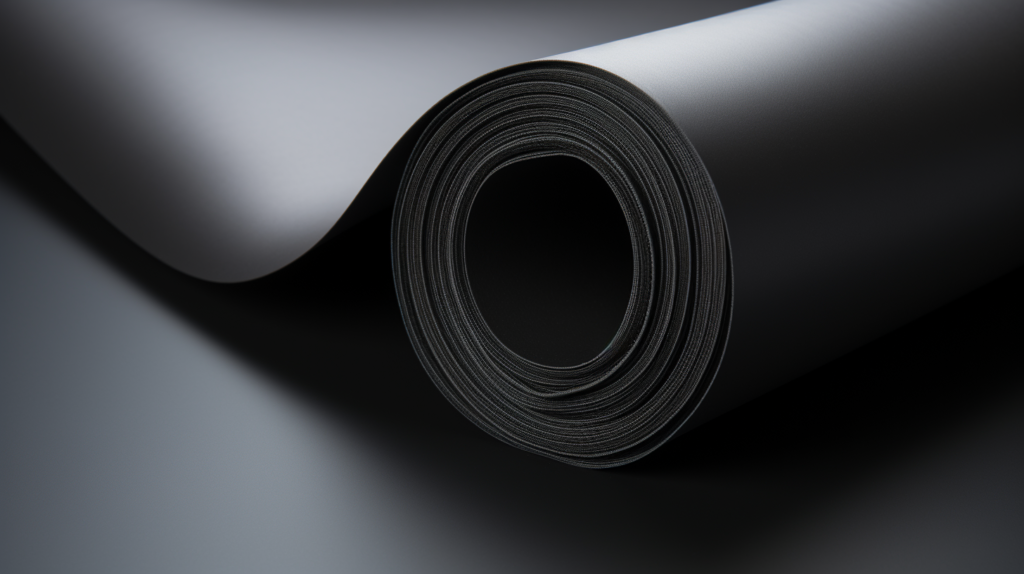

Mass loaded vinyl (MLV) is a type of dense, heavy duty vinyl sheeting that contains deliberately added mineral filler agents to increase its weight and improve sound blocking capabilities.

These fillers, typically barium salts or calcium carbonate powders, are incorporated into the vinyl material during manufacturing.

They give MLV an extremely high density and surface weight compared to regular vinyl products or common building materials.

The heavy mineral particles work by increasing the ‘limpness’ of the vinyl sheeting, while also providing mass to impede sound vibrations.

Typical MLV weights start around 0.5 pounds per square foot for thin membrane liners, ranging up to 1 pound per square foot for very high density underlayment grades.

This added weight is the key property that enables MLV to effectively absorb sound energy and reduce audible noise transmission.

MLV soundproofing materials are available in large rolls or sheets that can be cut onsite to fit the required area. The material is installed in floors underneath the finished flooring, or integrated into wall cavities as an inner mass loaded barrier layer.

MLV can be purchased through specialty acoustical product companies that focus on noise control applications. It is also available from some home improvement stores and general construction materials suppliers.

MLV comes in a range of product sizes and thicknesses. Typical thicknesses are 1/8 inch for lightweight grades up to 1⁄4 inch for the heaviest MLV underlayment.

Roll widths start around 48 inches wide and go up to 96 inches wide for easier handling and installation. Custom sheet sizes are also available from some manufacturers.

Does MLV Soundproofing Work?

Yes, MLV can definitely help improve soundproofing and noise control. However, it performs best when properly used as flooring underlayment, as opposed to wall or ceiling applications.

Installed below flooring, MLV underlay provides excellent acoustic isolation by absorbing impact noises and footfall sounds before they can vibrate through subflooring.

This makes MLV an ideal solution for multi-family housing situations like apartments and condos where containing footfall noise is critical.

On walls and ceilings, MLV by itself is far less optimal for soundproofing.

Thin MLV membranes lack the required thickness, density, damping, and air sealing to adequately block noise transmission through overhead planes or vertical cavities.

While MLV wall liners can marginally improve mid-high frequency sound blocking, lower frequencies easily pass through with minimal impedance.

Therefore, MLV should not be used as the sole product for wall or ceiling soundproofing projects, but rather one component of a multilayer assembly.

A wall lined with only MLV will perform poorly, with many weak points for flanking and minimal impact on low frequency noise.

Combining MLV with insulation, sealants, multiple drywall layers and isolation hardware results in substantially better acoustic separation on overhead and vertical surfaces.

MLV performs notably better for flooring applications compared to walls or ceilings when used appropriately. It excels at reducing footfall impact noise transfer through subflooring.

But relying solely on MLV for overhead or vertical soundproofing often yields disappointing results. Proper soundproofing requires the right combinations of products used strategically.

How MLV Reduces Noise?

The noise reducing capabilities of MLV stem from its uniquely heavy mass density and limpness compared to common building materials. The high surface weight enhances sound isolation in several ways.

First, the MLV mass provides inertial resistance that dampens vibrational energy instead of letting it pass into structural elements. Sound waves attempting to travel through floors, walls or ceilings are impeded by the dense MLV barrier. This diffuses the initial energy of airborne sound waves striking the membrane.

Additionally, MLV blocks direct airborne noise pathways through its sheer density and limp flexibility. Sound waves cannot as easily travel straight through the thick MLV membrane, but instead become scattered and dispersed. This converts some of the acoustic energy into subtle heat losses inside the material.

For flooring applications, MLV is highly effective at absorbing impact noises and footfall sounds in the mid to high audible frequency range. This encompasses most problematic impact noises from sources like walking, furniture shuffling, appliances, dropped objects, children playing, pets, etc.

MLV can also marginally improve sound blocking in wall assemblies, though it requires supplemental materials to perform optimally. The MLV mass helps reduce the transmission of mid-high frequency noises like speech, TV, and music. But substantial low frequency noise passes through thin MLV membranes unless combined with additional mass and damping components.

How To Use MLV for Soundproofing?

The most reliable and cost-effective use for MLV is as an underlayment below flooring surfaces to reduce impact noise transfer between rooms.

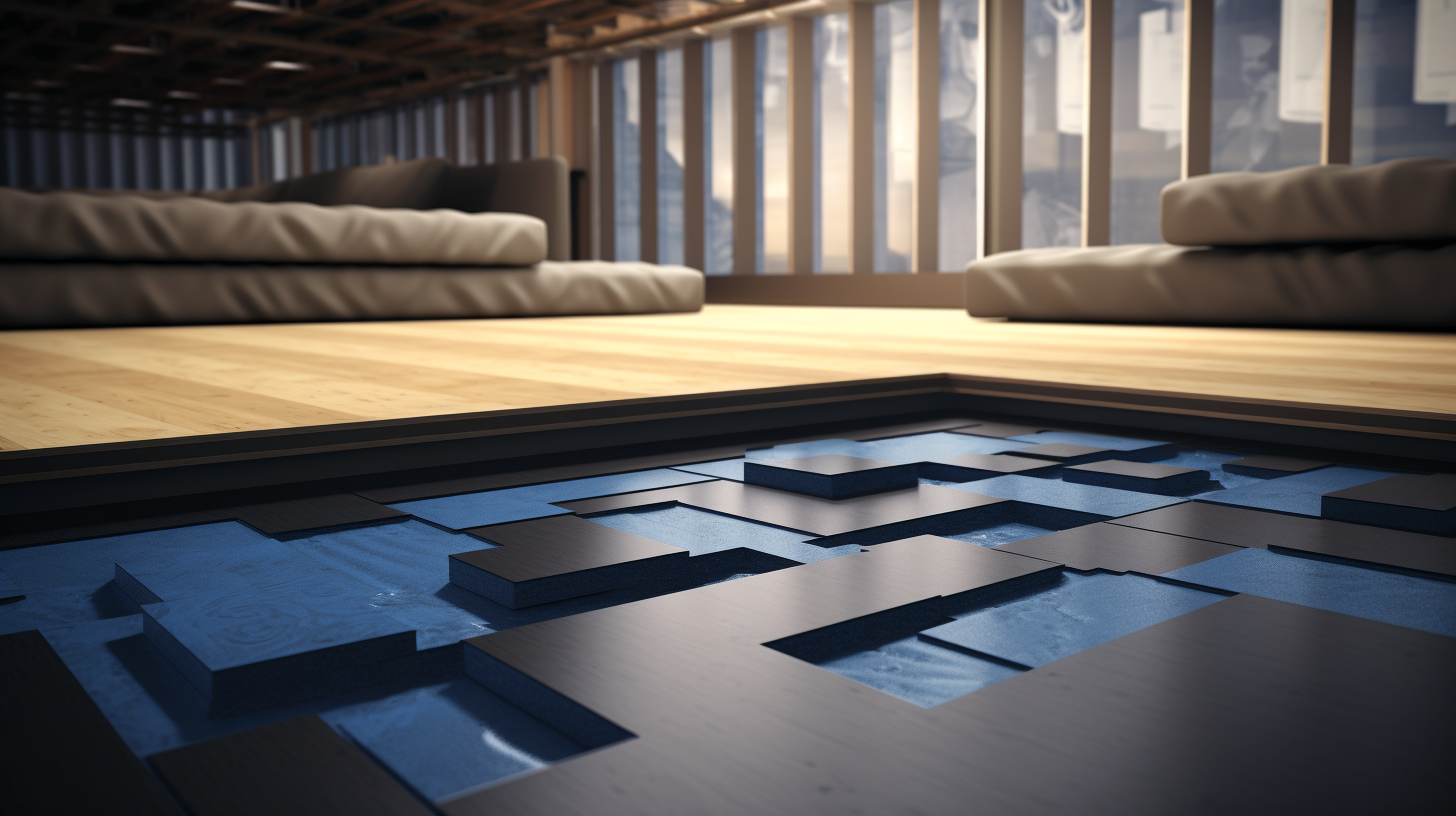

Here, it can provide a marked improvement in acoustic isolation for multi-level structures. MLV is installed as a floating layer decoupled from subfloors using foam perimeter isolation strips.

Additional foam underlay is often layered above it for moisture protection.

Typical flooring materials installed over MLV underlay include laminate flooring, engineered hardwood, luxury vinyl plank, tile, and carpeting.

Correct installation ensures the MLV underlayment is perfectly flat, clean, and seam taped underneath the finished floor.

Perimeter isolation strips are crucial for preventing noise flanking at edges. The finish flooring then floats over the MLV, either gluelessly clicked/locked in place or using flooring adhesives if needed.

For walls, very thin and lightweight 0.5 lb/sq ft MLV grades are much easier to work with. MLV wall liners are affixed using adhesive, fasteners, or friction fit within stud cavities.

However, even with multiple layers of drywall over it, thin MLV alone performs poorly on walls, allowing significant noise penetration.

Far better acoustic separation is achieved by supplementing wall MLV with insulation, sealants, and isolation hardware.

What Are The Limitations of MLV?

While excellent for flooring noise control, MLV has notable limitations if incorrectly used for wall or ceiling soundproofing applications.

MLV by itself lacks the required properties to optimally block noise transmission overhead or through vertical cavities.

There are several key deficiencies when MLV is adapted outside its intended underlayment usage.

A major weakness is that lightweight MLV membrane cannot adequately block lower frequency noise like home theater bass or music.

These low frequency vibrations easily pass through thin MLV unimpeded. This results in audible rumbling and music penetrating through walls and ceilings lined only with MLV.

The minimal thickness also leaves many opportunities for noise flanking around edges, electrical boxes, and outlets without extensive sealing.

MLV also provides no sound absorption or damping – noises reverberate off the hard vinyl surfaces. And MLV does nothing to address impact noises generated within a room itself.

For these reasons, MLV should only be one supplemental component of wall and ceiling assemblies, not the primary sound blocker.

Strategically layered thin MLV adds mass, but insulation and multiple drywall layers improve performance far more noticeably.

For well-rounded noise control, MLV must be combined with air sealing, damping materials, and isolation techniques.

Even heavy grades of MLV become tricky to install overhead as a ceiling liner. The dense material wants to sag over time when installed horizontally.

Substantial mechanical fastening or adhesive support is needed to compensate for the weight. MLV also requires very careful cutting and fitting around electrical, lighting, and HVAC components on ceilings.

For these reasons, lightweight insulation makes a better primary noise blocker for overhead and vertical applications.

Best Practices for Installing MLV

To leverage MLV most effectively, it is critical to use the proper product grade and design suited for each assembly scenario.

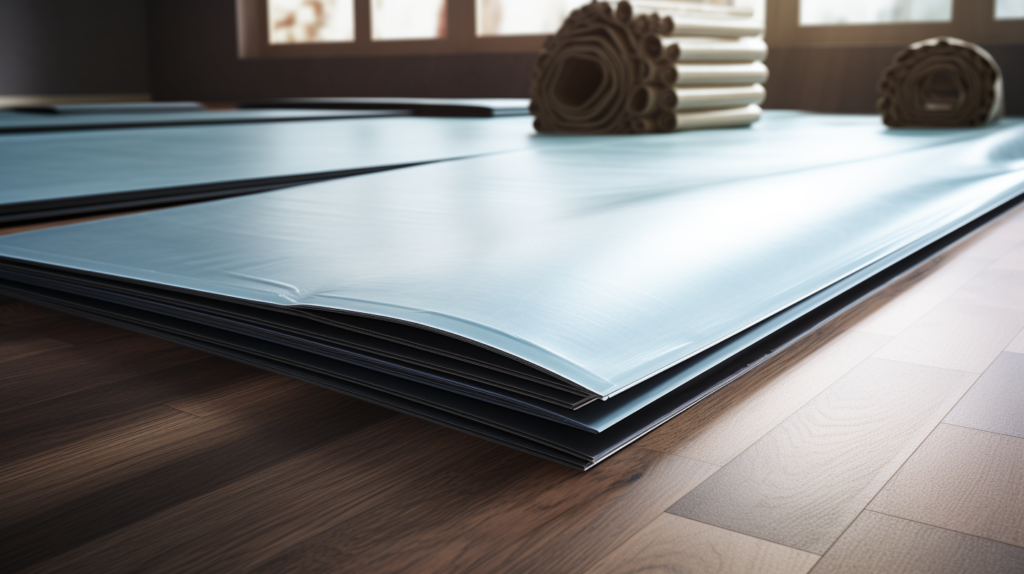

For flooring applications, quality underlayment-grade MLV should be installed under a well-constructed floating floor system.

Per manufacturer guidelines, allow small gaps at seams and perimeter, and combine MLV with foam underlay for compression and moisture protection.

It is not recommended to use MLV alone expecting robust acoustic separation on walls and ceilings.

Include MLV as just one supplemental component within a multilayer assembly filled primarily with insulation.

Use thin MLV to strategically add mass without overloading structures. Combine MLV membranes with multiple drywall layers, sealants, isolation clips, and insulation for well-rounded acoustic performance.

MLV certainly can enhance soundproofing projects when applied correctly. But it also has inherent limitations, so products and assemblies must be specified appropriately.

Prioritize MLV underlayment for flooring noise reduction, and use it selectively on walls and ceilings to supplement other materials and techniques.

With an informed installation approach, MLV can significantly improve sound isolation.

Conclusion

In closing, MLV can be an excellent addition to certain soundproofing applications when used properly.

As an underlayment for floating floors, quality MLV membranes provide substantial impact noise reduction between rooms.

The limp heavy mass impedes footfall vibrations and absorbs airborne sounds. However, limitations emerge when MLV is adapted to wall or ceiling uses where it cannot perform as the primary noise blocker alone.

For optimal overhead and vertical soundproofing, MLV should be combined with insulation, multiple drywall layers, sealants, and isolation hardware as just one supplemental component.

With an informed design approach leveraging MLV selectively, impressive noise control is achievable in residential and commercial spaces alike.

Focus on the proper product grades and applications to unlock the full potential of mass-loaded vinyl.