Have you ever wondered if that old memory foam pillow or the normal foam from your discarded couch could serve a new purpose as acoustic foam?

The idea may sound far-fetched, but it’s a question that has sparked curiosity and debate among DIY enthusiasts and acoustic experts alike.

This article delves into the complexities and potential of using memory foam and normal foam as alternatives for traditional acoustic foam.

We’ll explore their inherent properties, effectiveness in sound absorption, and the practical considerations involved in repurposing these materials for acoustic treatment.

It’s a subject that goes beyond mere speculation, touching on issues of sustainability, cost-efficiency, and acoustic performance. So let’s dive in to unravel the facts and fictions surrounding this intriguing topic.

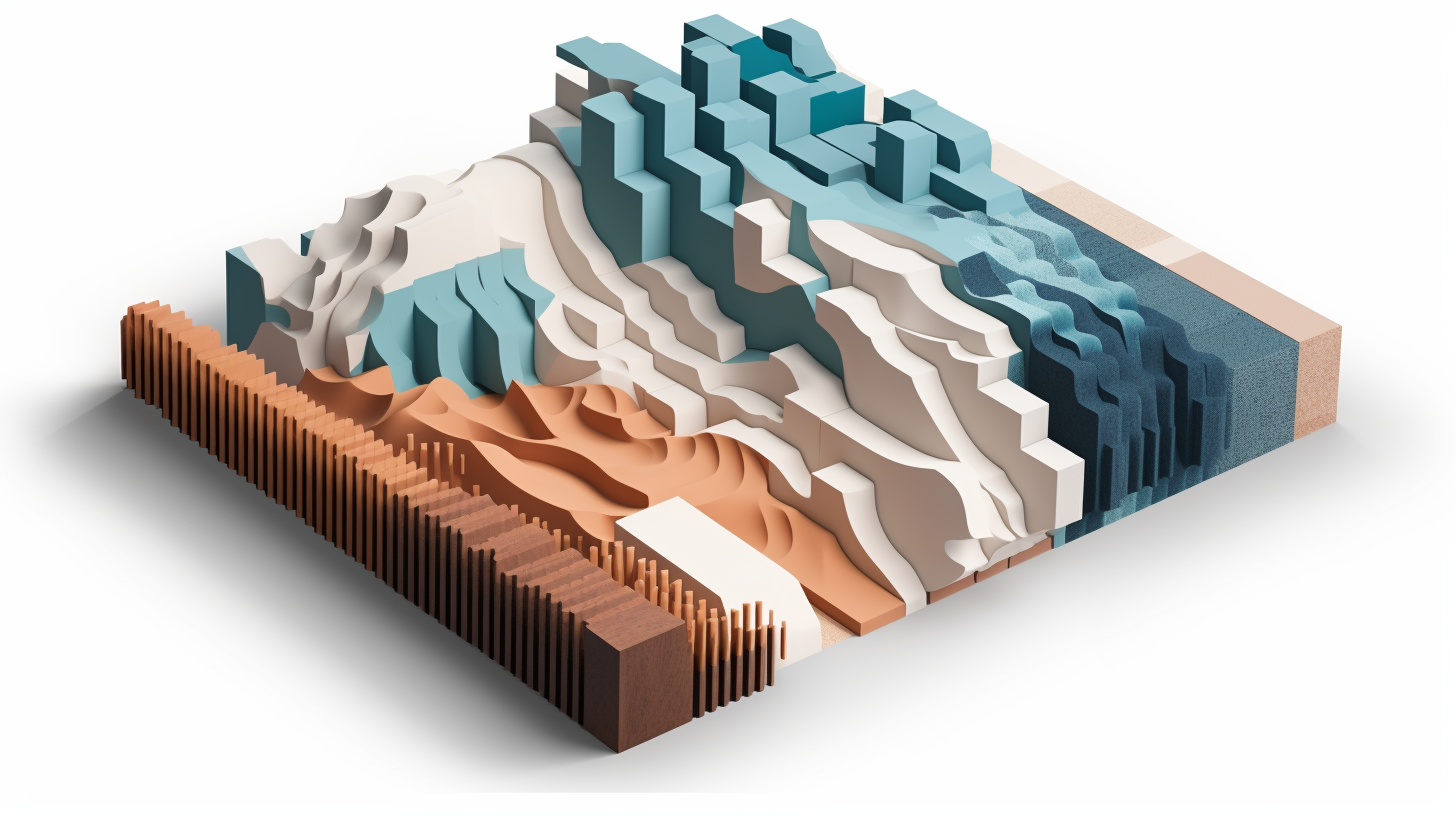

Originally, What Is Acoustic Foam Made From?

Acoustic foam, a specialty product specifically designed for sound control applications, has been a mainstay in the industry for several decades.

It is meticulously engineered to absorb, diffuse, and attenuate sound energy.

Acoustic foam is mostly made from polyurethane foam imbued with specific properties to make it a formidable tool against unwanted noise and echo.

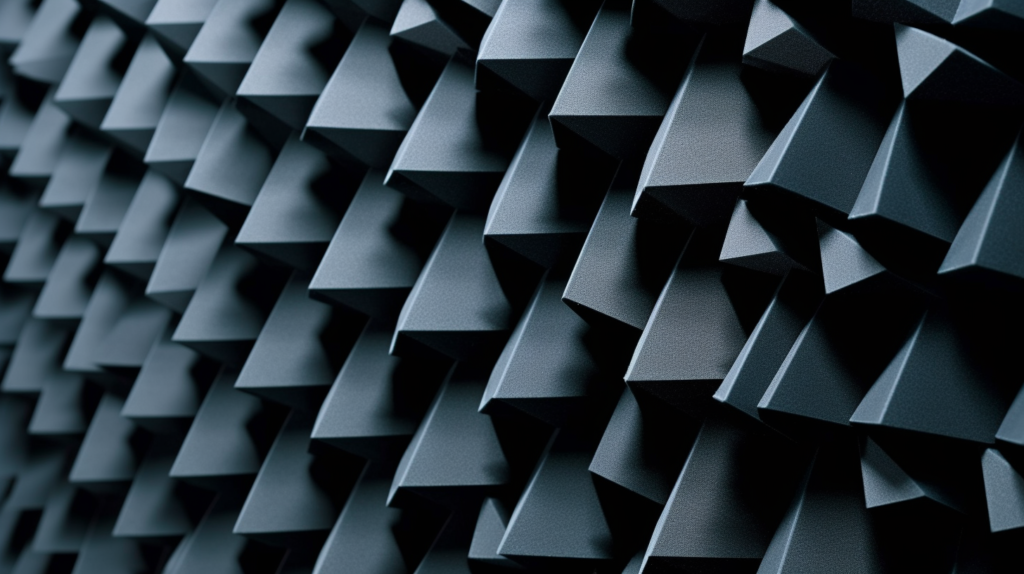

The foam often comes in various designs, including wedges, pyramids, and egg-crate styles, to further enhance its sound-absorbing capabilities.

The science behind the efficacy of acoustic foam lies in its material and design. Polyurethane foam is known for its open-cell structure, which allows it to trap and absorb sound waves efficiently.

When sound waves encounter this foam, they penetrate its open-cell structure, losing energy in the process.

This loss of energy translates to less echo and ambient noise, creating a more controlled sound environment.

Given its effectiveness, acoustic foam is usually the first choice for those seeking to improve the acoustics of a room.

What is Normal Foam?

The term “normal foam” is broadly used to describe conventional foam materials that are not specifically engineered for acoustic applications.

These can include various types of foam, such as polyurethane, polyethylene, and others.

These foams find their application in a plethora of products, ranging from cushioned furniture and car seats to bedding and packaging materials.

While they excel in providing comfort and support, they are not designed with sound absorption as a primary function.

Normal foam is available in a range of densities and firmness levels, each suitable for different applications.

High-density foam, for example, offers durability and support, making it ideal for furniture and mattresses.

On the flip side, lower-density foam tends to be softer and is usually used where comfort is a priority.

When it comes to acoustic treatment, the density and firmness of these foams can vary in their effectiveness, either serving as an asset or a limitation based on how they interact with sound waves.

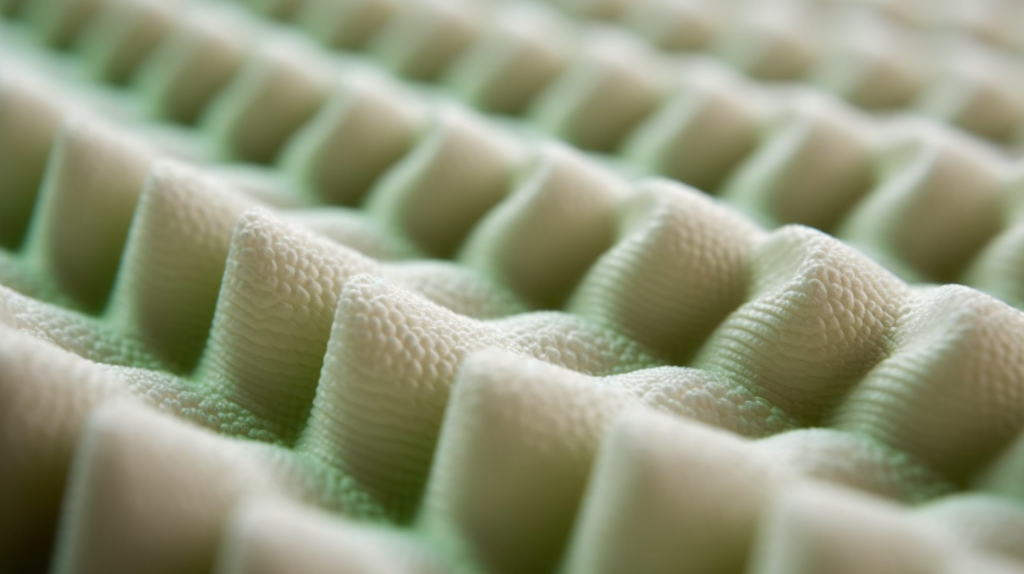

What is Memory Foam?

Memory foam is a specific type of foam made from viscoelastic material.

Its unique combination of properties makes it ideal for pressure relief and contouring support, often seen in applications such as mattresses and pillows.

The question of its utility in acoustic treatment, however, is an intriguing subject that warrants further investigation.

The density and viscosity of memory foam give it a unique “hugging” sensation.

When you press against the foam, it slowly returns to its original shape, demonstrating its slow-recovery or “memory” properties.

While these attributes make it a popular choice for bedding and orthopedic needs, they present a set of unique characteristics that could either enhance or hinder its capabilities for acoustic treatment.

For example, its density may lend it effectiveness in absorbing lower-frequency sounds, but its inherent viscoelastic properties and closed-cell structure could limit its overall sound-absorbing capabilities.

Can Normal Foam be Converted into Acoustic Foam?

Yes, converting normal foam into acoustic foam is a viable option, particularly if you’re looking for a sustainable and cost-effective solution.

The key is to select normal foam with a higher density; polyurethane acoustic foam, for example, typically has a density of about 50kg/m^3.

The process itself is straightforward. Simply cut the high-density normal foam into the shapes you desire and place them where needed.

However, for effective acoustic treatment, it’s advisable to cover at least 30% of the room’s surfaces with the foam.

Can Memory Foam be Converted into Acoustic Foam?

Yes, the unique viscoelastic properties of memory foam make it a candidate worth considering for acoustic applications.

Typically, the density of memory foam is approximately 95kg/m3 which is even higher than that of specialized acoustic foam, which often hovers around 50kg/m³.

This higher density potentially makes memory foam effective at absorbing lower-frequency sounds.

However, it’s essential to note that the closed-cell structure of memory foam may limit its effectiveness at trapping higher-frequency sound waves.

Therefore, while it may excel in certain acoustic applications, it might not be a one-size-fits-all solution.

Cost is another significant consideration. Memory foam tends to be more expensive than both normal foam and specialized acoustic foam.

If you’re contemplating a large-scale acoustic treatment project, you’ll need to weigh the potential acoustic benefits against the financial investment to determine if repurposing memory foam is a viable option.

In practical terms, if you decide to use memory foam for acoustic treatment, aim to cover at least 30% of the room’s surfaces to achieve effective sound absorption.

Comparing Normal Foam, Memory Foam, and Acoustic Foam

When contemplating alternative materials for acoustic treatment, a comprehensive comparison against specialized acoustic foam is essential.

One industry-standard measurement for this is the Noise Reduction Coefficient (NRC), which quantifies a material’s sound-absorbing capabilities.

Our guess is that memory foam will have higher NRC on the lower end of sound spectrum due to it’s density.

Which works the same way with polyester acoustic panels that has about 4 times higher density than your normal acoustic foam.

Since normal foam might be made with the same material as your specialized acoustic foam, they will have about the same NRC across the sound spectrum if the density is the same.

Cost-wise – normal foam usually comes in as the most economical option and is thus attractive for budget-conscious endeavors.

Acoustic foam falls in the moderate price category, given its specialized marketing for sound absorption.

Memory foam tends to be the most expensive, but this cost may not be a significant factor if you’re repurposing existing memory foam products.

If you go this route, ensure that you have enough material to cover at least 30% of the room’s surfaces for effective sound absorption.

Otherwise, you may need to supplement with acoustic foam, which could result in aesthetic differences due to variations in color and design.

As for longevity, memory foam is generally considered to be more durable than both normal and acoustic foams, potentially offering a longer lifespan in acoustic applications.

However, it’s worth noting that memory foam can yellow over time, which could be an aesthetic concern.

Factors to Consider When Repurposing Foam for Acoustics

If you’re considering the innovative approach of using normal or memory foam for acoustic applications, several crucial factors should be on your radar.

The first is the foam’s physical characteristics, such as its thickness and shape, which can significantly influence its sound-absorbing efficiency.

Generally, thicker foam excels in absorbing lower-frequency sounds, while thinner foam is more apt for higher frequencies.

Furthermore, foam designed with additional surface area—think ridges or patterns—may offer superior sound absorption compared to a flat piece.

Fire safety is another essential consideration.

While traditional acoustic foams often receive fire-retardant treatments to comply with safety standards, normal and memory foams may not have these fire-resistant properties, especially if they were initially designed for non-acoustic applications.

If you opt to use these alternative materials, treating them with a fire retardant could be necessary to meet safety regulations.

Or you can simply just ignore it understanding fire safety – I suspect the foams won’t catch fire and spread fire, especially for viscoelastic foam or your memory foam.

DIY Tips for Converting Memory Foam and Normal Foam into Acoustic Panels

Transforming memory foam or normal foam into acoustic foam can be a rewarding DIY project if executed correctly.

The first step involves selecting the type of foam that will best meet your acoustic needs. Once you’ve identified the foam, the next step is to cut it into the desired shapes and dimensions.

This is where creativity can come into play; unique shapes and layered designs can enhance the foam’s sound-absorbing capabilities.

However, it’s crucial to adhere to safety guidelines, particularly regarding the use of cutting tools and chemicals for treating the foam.

Once your foam pieces are cut and ready, the next step is mounting them on your walls or desired surfaces.

This process can be as straightforward or as complex as you make it.

Some people opt for simple solutions like adhesive sprays or double-sided tape, while others prefer constructing wooden frames to house the foam panels.

The choice largely depends on your specific needs, the weight of the foam, and the surfaces you’re working with.

Do take note that you will have to cover 30% of surfaces to have effective acoustic treatment.

Keep in mind that improper mounting can compromise the effectiveness of your acoustic treatment, so it’s essential to consider the pros and cons of each method carefully.

Conclusion

The world of acoustic treatment is not limited to specialized acoustic foam. Normal and memory foam offer intriguing, potentially cost-effective alternatives.

Each has its pros and cons: specialized acoustic foam is engineered for sound absorption, normal foam is budget-friendly, and memory foam’s high density may excel in absorbing low-frequency sounds.

Key considerations include the Noise Reduction Coefficient (NRC), cost, and longevity.

For DIY projects, covering at least 30% of a room’s surfaces with your chosen material is crucial for effective sound treatment.

In summary, while traditional acoustic foam is a reliable choice, normal and memory foam present viable alternatives when carefully considered and properly implemented.