Struggling to hear your music clearly over fan noise? Finding it impossible to make out movie dialogue with windows open? Acoustic foam may help tame distracting sounds interfering with your listening pleasure.

Acoustic foam offers noteworthy perks by absorbing problematic room reflections and ambient noise for cleaner playback.

But drawbacks like costliness and low-frequency ineffectiveness do exist.

Let’s dive into the key pros and cons around acoustic foam to see if utilizing these sound-absorbent panels works favorably for your situation.

What Exactly is Acoustic Foam?

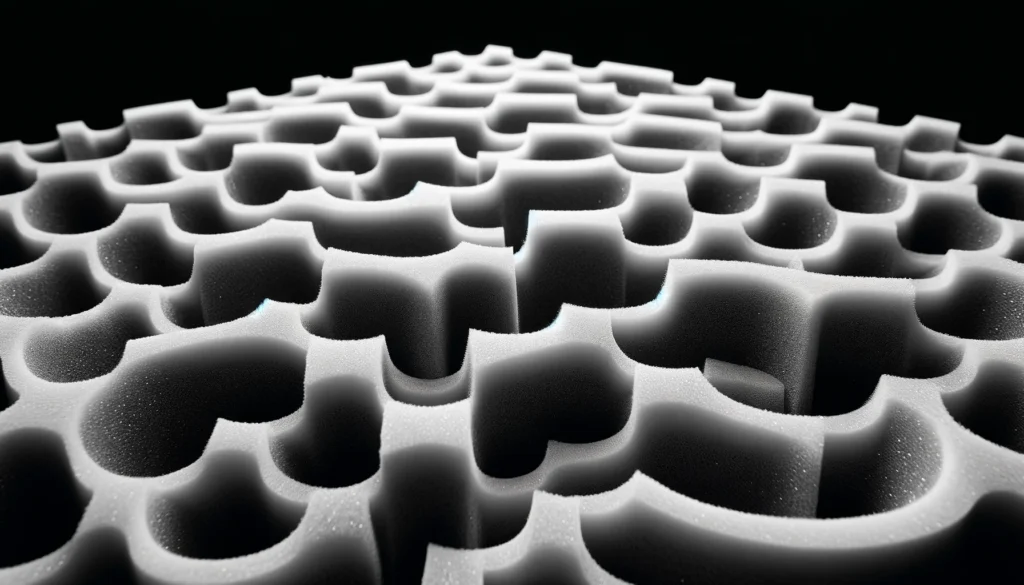

Acoustic foam refers to porous, synthetic materials engineered to absorb audible sound energy.

Manufactured in rigid panel form, they mount onto walls, ceilings and other reflective surfaces using adhesives.

There they reduce echoes, flutter echoes and uneven resonances which can otherwise distort playback fidelity and clarity.

We’ll explore the benefits and drawbacks around using acoustic foam more below.

But in short – it helps control room acoustics effectively yet lacks complete soundproofing capabilities.

Improves Sound Quality

Acoustic foam is able to absorb echo, reverb, and unwanted reflections in a room in order to provide improved sound quality within that room.

The sound waves which bounce off the walls and various surfaces in any given room can often distort or degrade the clarity of audio being played in it.

By placing acoustic foam treatments on these reflective surfaces, many of these errant sound waves can be absorbed instead of bounced around the space.

This leads to a reduction in troublesome issues like flutter echoes, standing waves, and uneven room resonances which can negatively color the listening experience.

With these minimized, audio playback can sound much clearer and closer to the original source material.

Vocal performances, musical instruments, and speakers will come across more cleanly and accurately after acoustic foam installation since excess reverberation and frequency buildups are reined in.

Overall fidelity and imaging improve as a result.

Many recording studios, audiophile listening rooms, home theaters and the like utilize acoustic foam for its ability to tame issues inherent to the dimensions, materials, and geometry of the given space.

By controlling unwanted reflections and resonances, the sound quality in the space is greatly enhanced.

This allows audio engineers, producers, musicians, cinephiles, and casual listeners to get closer to hearing media as the creators intended.

The precise absorption characteristics of acoustic foam also assist in delivering a flatter, more neutral frequency response from a room.

So rather than certain bass or treble elements being exaggerated while others get canceled out from phase issues or room modes, the full spectrum comes through smoothly.

This wider, more even sonic profile creates a richer, more engaging listening experience.

Lowers Background Noise

Another major benefit offered by properly installed acoustic foam is reducing the level of background noise which may impede wanted sounds.

Ambient noise from computer fans, traffic outside, HVAC systems, and general household activities can easily bleed into and distract from music playback or video watching if a room is too live.

Sound from inside and outside the space bounces around off untreated walls and ceilings, becoming an unintended part of the listening environment.

Strategically placed acoustic foam absorbs much of this nuisance noise before it can reflect back into the room.

Vocals from media sources or conversations can be hard to discern when fighting a buildup of ambient noise.

But by using acoustic foam to dampen these unwanted sounds as they bounce around the space, intelligibility greatly improves.

Media dialogue, singing voices, and other key sonic elements come through clearly since they do not have to compete as much with AC units humming or dogs barking outside.

This allows listeners to pick out finer details and nuances which would otherwise become lost or jumbled together.

Through lowered background noise, acoustic foam further enhances audio fidelity much like it does via diffusion and absorption of deleterious reflections.

Aesthetically Pleasing

A nice ancillary benefit of acoustic foam beyond its acoustic properties is that it comes available in a wide variety of aesthetic styles to match different room décor.

Foam panels can be purchased with or without fabric coverings in a rainbow of color choices from subdued to vibrant.

Variances in material density also lend unique textures and visual depth to the foam itself before any coatings come into play.

This ability to color match or complement existing furnishings while softening hard, sterile surfaces makes acoustic foam treatments popular from a design perspective too.

Instead of needing to tolerate ugly, industrial-looking blocks wedged chaotically around the room for the sake of acoustic performance, foam pieces can blend into or dynamically stand out within the space as desired.

They end up looking like paintings, headboards, wallpaper or something purposefully decorative.

The sound dampening goals get achieved along with making the room more visually inviting.

And since acoustic foam is lightweight and easily cut to size, fitting pieces snuggly around objects, doorframes, light fixtures, etc becomes simple.

Creative patterns, gradients, and coverage area ratios can add great visual flair.

Carefully considered acoustic foam placement treats the eyes and the ears in one fell swoop.

Easy to Install

Yet another reason why acoustic foam has become a go-to sound treatment option comes from its user-friendly installation process.

Applying foam panels to the necessary surfaces within a space can be easily accomplished by a single person without much hassle or learning curve involved.

Most acoustic foam comes with a peel and stick adhesive backing, allowing it to be mounted directly onto drywall, brick, concrete, wood and the like after a quick cleaning.

Many also have interlocking jigsaw-type edges allowing seamless connections between adjoining pieces.

This enables custom layouts to come together quickly.

And using standard razor blades or hot knives, the foam cuts with ease to fit odd dimensions or work around outlets and hardware.

If plans change down the road, the non-permanent adhesive usually allows the pieces to be removed intact for reuse elsewhere too.

Compared to mounting rigid fiberglass panels or building complex bass traps which both require precise construction skills, acoustic foam offers flexibility.

Measure, stick, slice, and place — in an afternoon an amateur can start reaping the sound benefits and learning as they experiment with arrangements.

Much easier than needing to fabricate custom wood frames or anchor each piece mechanically.

Acoustic foam’s smooth workflow helps first-timers dip their toes into room treatments without added installation headaches.

Doesn’t Block All Sound

While acoustic foam stands out for its balanced set of strengths in the soundproofing arena, it does come with some inherent limitations too.

No acoustic foam solution can completely soundproof a room 100%.

Being a porous absorber designed chiefly to combat mid to high frequency reflections, acoustic foam lacks adequate density to block very low bass and sub-bass frequencies from transmitting.

These longer sound waves pass too easily through standard foam materials no matter the thickness or layering quantity used.

Even high performance varieties with somewhat better density cannot rival heavy mass-loaded barriers or purpose-built bass traps for truly stopping deep vibrations.

So as a tradeoff for its superb midband absorption traits and lighter weight, acoustic foam cannot prevent the transmission of voices, footsteps, or loud subwoofer rumble through floors and walls on its own.

Augmenting foam pieces with seals, caulking, weatherstripping and supplemental bass trapping gives the best overall performance for restricting all noise.

Another acoustic shortcoming stems from foam’s need for supplementary products to achieve complete room coverage.

Small foam panels alone treat only a fraction of the problematic surface area in a space and remain incapable of resolving certain fundamental issues tied to a room’s three-dimensional shape.

Standing waves, flutter echoes and uneven low-frequency resonances often necessitate additional large bass traps or diffusers to correct — especially in smaller spaces.

So while tremendously helpful for smoothing out mid and high-frequency reflections, acoustic foam panels work best when strategically combined with other acoustic treatments like panels and clouds for comprehensive sound quality enhancement from top to bottom.

Expecting peel-and-stick foam pieces alone to solve all acoustic problems usually leads to disappointment.

Integrating them as part of a cohesive system though allows acoustic foam to excel.

Can Be Expensive

From a cost perspective, acoustic foam ranks as one of the pricier options out there for taming room acoustics with maximum effectiveness.

Part of this stems from manufacturing methods that balance acoustic functionality, longevity, durability and aesthetics.

Keeping foam panels light yet sturdy with consistent pore structure and reliable adhesives necessitates careful engineering and quality control during construction.

This runs counter to most shoppers’ desires for the cheapest cost possible.

And market demand supports premium pricing too since professional studios and home theaters eye top-tier acoustic performance over budget restrictions when sound quality sits paramount.

Safety requirements also bump up material expenses when flame-retardance and low VOC-emission standards come into play.

Overall these essential characteristics makes quality acoustic foam more of a prosumer product, out of reach for many casual listeners simply wanting basic echo reduction as cheaply as possible.

Significant variability between different foam manufacturers and product lines also rears its head with pricing.

Thicker, denser panels with more advanced multi-layer constructions logically demand higher prices than budget single-layers.

Unique materials like melamine, molded polyurethane and expanded PVC foams also trade blows with traditional egg crate and poly-foam varieties — each carrying its own performance-to-price ratio.

And markup inflations do sneak in with some brands too.

Yet the laws of diminishing returns still apply at the ultra-high-end just the same.

In most cases, economically priced mid-tier acoustic foam delivers excellent value and audibly outperforms budget picks.

So while not the cheapest sound treatment around, acoustic foam delivers satisfying acoustic benefits without requiring investors’ bank accounts in many situations.

Needs Occasional Replacement

Another less advertised downside to acoustic foam surfaces in the need to replace panels every so often as they wear out over time.

Much like the cushions on a couch, acoustic foam loses some of its beneficial properties after years being squished and re-expanded from perpetual sound wave impacts.

The materials degrade while collected dust and particles clog up the delicate pore structures required for absorption.

Environmental factors like humidity, sunlight, chemical exposure and simple aging also slowly damage the foam’s integrity at the molecular level.

As a result of these unavoidable processes, old foam turns brittle and compressed with frayed fabric and crumbling adhesive.

The decrepit state leaves it acoustically transparent — no longer able to hamper noise like when newly installed.

So while acoustic foam does not degrade nearly as quickly as cheaper packing or upholstery foams, it does become mandatory to swap panels out after around 5 to 10 years in most home environments.

Studios may require replacement even sooner.

This necessary maintenance makes acoustic foam less permanent than rigid fiberglass or mineral wool panels.

But compared to continually repainting walls, re-staining wood panels or replacing worn carpet every few years, refreshing acoustic foam remains reasonably convenient and economical.

A small ongoing investment helps maintain excellent acoustic quality long-term.

Can Trap Dust and Allergens

The necessary porous and fibrous composition of acoustic foam lends itself easily to trapping airborne dust, pollen, pet dander and other particle pollutants floating through a space.

As sound energy passes into the open cavities within the foam, microscopic contaminants ride along and become lodged deep inside the maze-like interior.

This undesirable perk of acoustic foam unfortunately makes keeping pieces clean a Sisyphean task.

Vigorously vacuuming the surface or wiping panels down with a damp cloth only catches some of the buildup near the facade.

Allergens and microbes continue festering out of reach inside, accumulating over time to possibly hazardous levels.

And since acoustic foam has lots of nooks and crannies by design across its craggy face, hand-cleaning the tiny voids grows impractical beyond the occasional spot treatment.

These undesirable particle-attraction traits require homeowners make concerted efforts keeping foam dust buildup at bay.

Periodic removal for deep cleaning or replacement both help refresh air quality and extend useful life.

Consider installing acoustic foam out of reach from pets or vent drafts as well to minimize contamination.

Those susceptible to allergies may want avoiding open-cell acoustic foam altogether too, opting instead for denser melamine or polyimide options which do not filter particulates as easily.

Or utilize natural linings like cotton or silk fabric over the foamface to create an air-blocking barrier.

With prudent precautions, homeowners can still benefit from acoustic foam’s noise reduction abilities without living amidst a rising tide of trapped allergens.

proper care brings the best of both worlds.

Conclusion

In conclusion, acoustic foam delivers tangible benefits for improving sound quality through reflection and resonance control.

But it does have limitations around low-frequency absorption and the need for supplemental bass trapping.

While convenient to install and available in attractive styles, acoustic foam remains costlier than other absorption options and requires replacement every 5-10 years as performance degrade from age.

And the porous nature welcomingly soaks up mid-high frequencies yet undesirably traps dust and allergens over time.

Still, with prudent precautions and realistic expectations around acoustic foam’s capabilities, it can significantly enhance listening spaces as part of a cohesive treatment system.