Have you ever noticed how sound echoes and reverberates in a room with hard, reflective surfaces?

It’s like being inside a cave!

Acoustic panels can help transform overly live spaces into balanced sounding environments by absorbing sound coming from multiple directions.

In this guide, we’ll explore how acoustic panels can work bidirectionally to control noise through careful material selection, strategic placement, and comprehensive acoustic testing.

Let’s dive in and learn how to leverage acoustic panels for superior sound control from all angles!

Why Sound Absorption Calls for Bidirectional Absorption

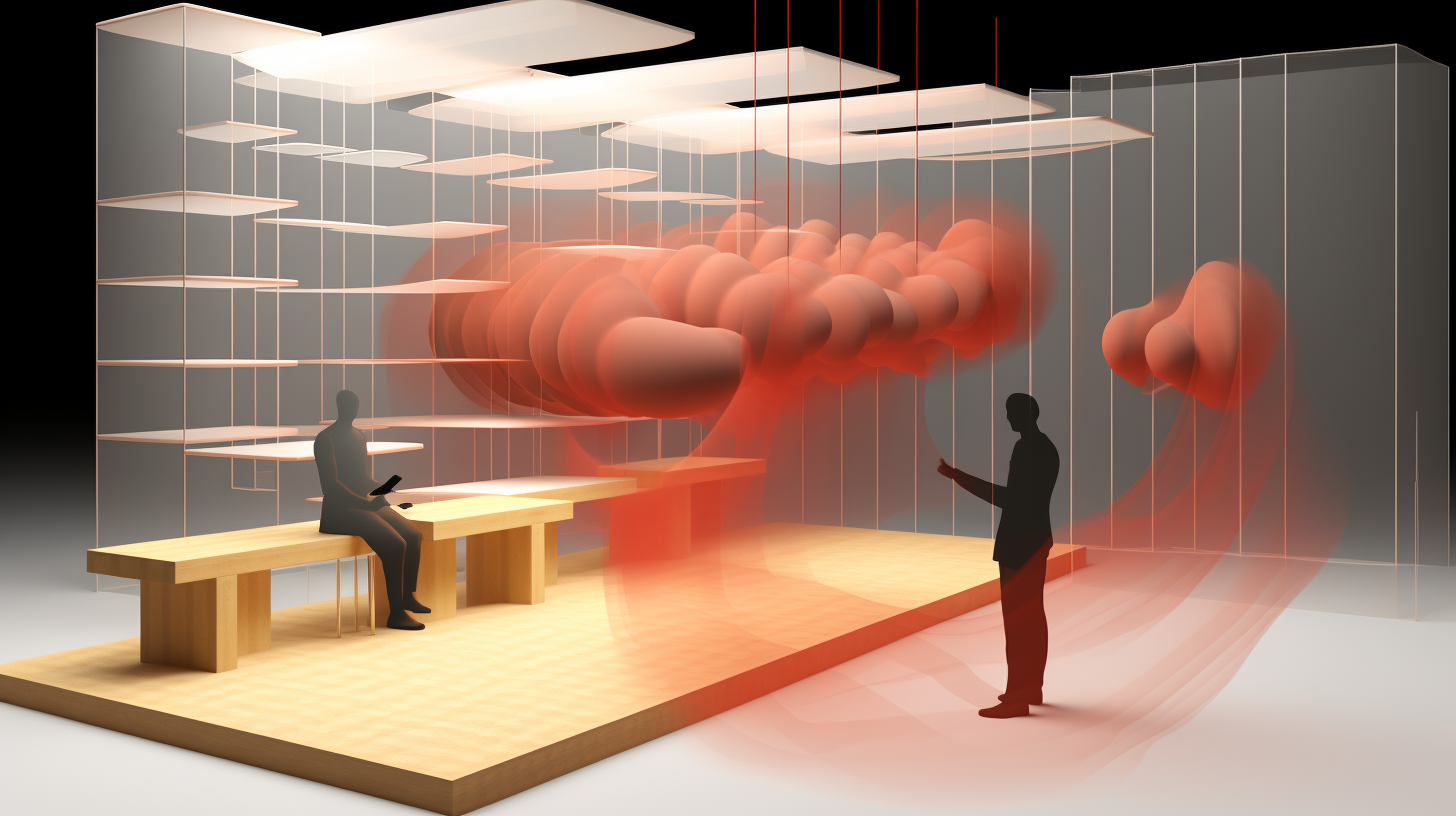

When considering acoustic panels for acoustic treatment, it’s important to understand how they can work in both directions to absorb sound coming from any angle.

The goal is to achieve omnidirectional absorption rather than allowing sound to continue reflecting around the room.

In this section, we’ll explore the key materials, designs, placement strategies, and testing methods that enable acoustic panels to effectively work both ways.

The Goal of Omnidirectional Sound Absorption

When it comes to acoustically treating a room, acoustic panels are a very popular way to reduce noise and echo.

But can these sound-absorbing panels work equally well in both directions to absorb sound waves and block sound?

Let’s take a closer look at how acoustic panels work both ways.

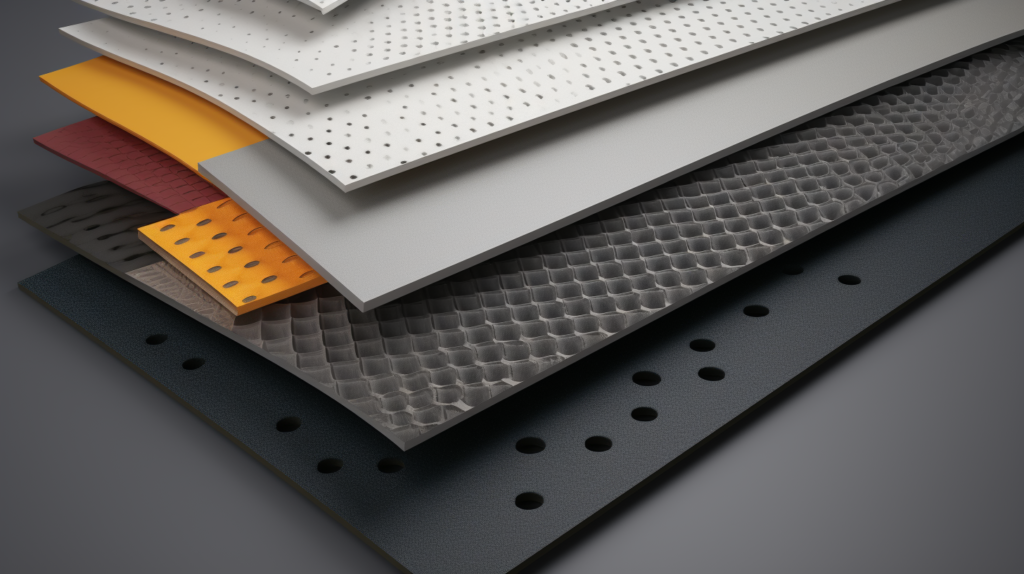

What Acoustic Materials Enable Bidirectional Absorption?

There are a few key acoustic panel materials that enable sound absorption from both directions during acoustic treatment. Many acoustic panels are made of porous polyester fiber or acoustic foam.

These types of acoustic materials are able to absorb incoming sound waves from either direction, allowing acoustic panels to work both ways.

Polyester fiber acoustic panels are a common option and are typically made from fiberglass or mineral wool.

These have an outer fabric facing but the inner material is porous.

This porous inner material is what enables polyester fiber panels to absorb sound waves omnidirectionally by converting the sound energy from the waves into heat energy upon contact.

This absorption occurs regardless of the direction the sound waves hit the panel.

Can Acoustic Foam Works Both Ways?

Another material often used in acoustic panels for acoustic treatment is acoustic foam, such as polyurethane foam or melamine foam.

Acoustic foam contains lots of small air pockets throughout its porous structure.

These pores within the foam absorb incoming sound waves from any direction by creating resistance that transforms the acoustic energy into very minor levels of heat.

This is how acoustic foam works so well to reduce noise and vibration in a room from all angles.

Omnidirectional Absorption is Key

Overall, polyester fiber, mineral wool, and acoustic foam all contain porous absorbent materials that enable acoustic panels made from them to work both ways for acoustic treatment.

The porous nature allows steady absorption of sound waves at a consistent rate no matter which direction the waves are coming from.

This capability makes them very suitable and effective materials for acoustic panels intended for acoustic treatment applications in both directions.

How To Choose the Best Acoustic Panels for Bidirectional Use

When selecting acoustic panels to effectively absorb sound in both directions, polyester fiber panels are a top choice.

Their materials and design make them uniquely suited for omnidirectional sound absorption.

Polyester Fiber Construction Optimized for All Angles

Polyester acoustic panels feature an outer perforated facing with small holes and an inner core of fluffy fiberglass or mineral wool.

This combination allows the absorption of sound waves hitting the panel from any direction.

Perforated Facings Don’t Limit Absorption Direction

The perforated facing allows sound to pass through into the inner material regardless of the angle it hits the panel.

This differs from directional panels that rely on shaping or facets to absorption. The facing ensures polyester panels work optimally for bidirectional use.

Inner Fibers Diffuse Sound Omnidirectionally

The inner fiberglass or rockwool core diffuses entering sound waves in all directions for thorough absorption.

The random fiber orientation scatters sound uniformly as it converts acoustic energy to heat.

Versatile Acoustic Treatment from All Angles

Polyester acoustic panels treat sound reflections and reverberation coming from any direction in a room.

Mounting them strategically enables omnidirectional acoustic control, perfect for soundproofing.

Pairing Polyester Panels with Foam and Bass Traps

Layering polyester panels with sound diffusing foam and bass trapping completes an acoustic treatment solution effective for bidirectional sound control.

The materials balance out their absorption capabilities.

In summary, polyester fiber acoustic panels allow superior omnidirectional sound absorption compared to other options, making them the top choice when acoustic treatment from all directions is needed.

Their ability to work both ways results in comprehensive acoustic control.

How To Test Acoustic Panel Effectiveness

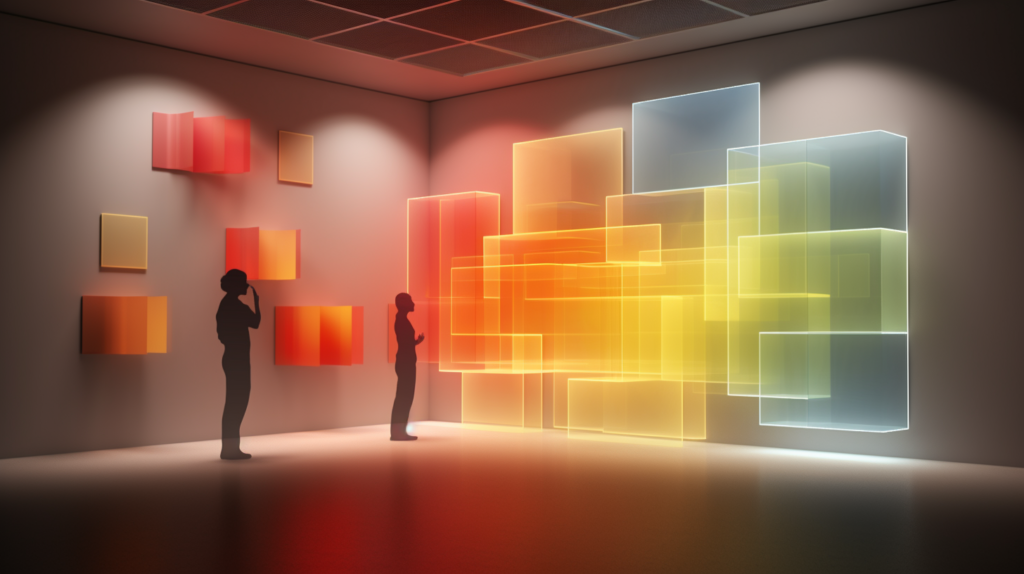

Setting up acoustic panels is one thing, but how can you systematically test their effectiveness in absorbing sound both ways for acoustic treatment?

Measuring reverberation time is the best approach for testing bidirectional sound absorption.

Use a sound level meter to take decibel readings from multiple room locations before installing the acoustic treatment.

Make test measurements from at least 3-5 positions around the room, both close to and far from your sound source.

After installing the acoustic panels on walls and ceilings, repeat the sound level measurements from the same room positions.

It’s best to use a consistent sine wave or broadband pink noise sound source, like a speaker playing a tone.

Analyzing Reverb Time Reduction

Now compare the room’s reverberation time, which is how long it takes the sound to decay by 60dB, with and without the panels installed.

A significant reduction in reverb time after installing the acoustic treatment indicates the panels are working bidirectionally to absorb sound rather than reflect it back around the room.

Checking Multi-Directional Absorption

For further validation, consider testing with sound generators placed in different corners of the room to check multi-directional absorption performance from all angles by your acoustic panels.

Detailed before and after measurements from multiple source and mic positions will provide you with quantifiable data on how well your Acoustic foam and other acoustic panels work both ways.

Validating Overall acoustic treatment Performance

Careful acoustic testing validates how well the panels perform as part of your overall acoustic treatment strategy. It also enables you to identify any remaining problem room modes that may require additional targeted absorption.

Key Takeaways on acoustic treatment with Acoustic Panels

When acoustic treating a room, using porous absorbent panel materials along with prudent placement enables acoustic panels to work both ways effectively.

Polyester, specialized foam, fiberglass and other permeable panel materials allow omnidirectional sound absorption from all angles rather than problematic reflections.

Optimizing Foam Shapes for Bidirectional Use

Angled and wedge-shaped acoustic foam can further improve bidirectional acoustic treatment performance.

The faceted shapes absorb sound from multiple angles rather than allowing problematic reflections.

Validating Performance with Careful Testing

Comprehensive sound level testing before and after installation provides quantification of how well your chosen acoustic panels absorb incoming sound waves from all directions.

Careful placement optimized for key reflection points also helps acoustic panels achieve their full potential for multidirectional acoustic treatment.

Achieving a More Ideal Acoustic Environment

With the right materials and some planning, incorporating acoustic panels is a great way to improve your acoustic environment by using them both ways.

Conclusion

In conclusion, acoustic panels can deliver effective omnidirectional sound absorption when the right materials and designs are leveraged.

Polyester fiber panels with perforated facings and porous inner cores offer versatile acoustic treatment, as do wedge-shaped foam panels.

Strategic placement targeting reflection points enables acoustic panels to work both ways.

Comprehensive testing validates the bidirectional effectiveness, helping ensure optimal acoustic conditions are achieved through the dual-directional absorption capabilities of well-designed acoustic panels.

With mindful material selection and installation, acoustic panels can transform an overly live environment into a balanced sounding space by absorbing sound coming from all directions.