Are damaged acoustic panels dragging down your studio sound?

While replacement may occasionally still prove necessary, most common acoustic panel damage like fabric tears, dents, or holes can be repaired effectively with the right materials and process.

Let’s dive into a step-by-step guide to professionally patching holes, covering cracks, rewrapping frayed fabric edges, and more to save your existing sound absorption without compromise.

Can You Repair Acoustic Panels?

Yes, in most cases minor to moderate acoustic panel damage involving things like fabric tears, dents, or small holes can be repaired rather than requiring full panel replacement.

We will explore the full process in detail below.

However, more severe issues compromising panel structural integrity may still warrant replacements.

Assess the Damage

It is important to thoroughly assess the damage to your acoustic panels before attempting any repairs.

Carefully examine the panel or panels in question and determine the exact nature of the damage.

Common issues include torn or frayed fabric, dents and cracks in the surface, holes, and panels coming unglued from their backing.

Make note of all visible damage for later.

You will also need to decide if the issues are merely cosmetic or if they negatively impact the acoustic performance of the panel.

Slight fabric tears or minor dents may not make a difference for how the panel absorbs sound.

More significant tears, holes, or cracks can allow sound to pass through unimpeded rather than being properly deadened.

In these cases, repairs are likely needed.

If the damage is very extensive, completely ruins the aesthetic, or fully compromises function, then replacement may be the best option over attempting repair.

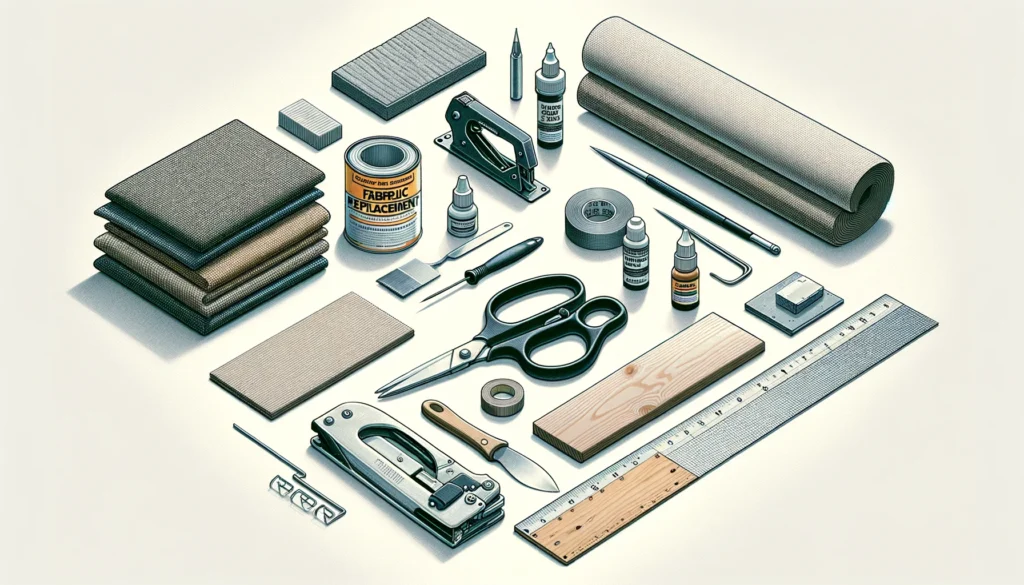

Gather Your Materials

Once you have thoroughly assessed the damage, it is time to gather the necessary materials and tools to make the needed repairs.

Having everything prepped in advance will allow the repair process to go much more smoothly.

If the acoustic panel fabric is torn, frayed, or needs replacement, obtain new fabric that matches the existing as closely as possible.

The fabric should be acoustically transparent and not overly thick.

Contact the manufacturer if unsure of the original fabric specifications.

In addition to replacement fabric, collect fabric glue or spray adhesive to securely bond the material to the panel surface.

For structural damage like dents, cracks, holes, or edge separation, you will also need filler compounds like lightweight putty or acoustic sealant.

These fill gaps and cracks to create an even surface.

Some acoustically transparent patches are also available.

Make sure any compound used is designed for acoustic panels rather than more heavy-duty wall fillers.

To install patches, covers, and new fabric, have tools on hand like sharp scissors, needles, thread, a staple gun and staples, and a razor blade utility knife.

Needle and thread can make fabrics easier to work with.

Staples and glue affix covers securely.

Scissors and knives carefully cut away torn original material when replacing acoustic panel fabric sections.

Clean the Panel

Before starting the actual repair work, take down the damaged acoustic panel or panels and thoroughly clean them.

Dust buildup, debris, stains, and so on can negatively impact adhesive and compound effectiveness.

Carefully vacuum fabric surfaces with a brush or upholstery attachment.

Use a microfiber cloth to wipe away any remaining dust or dirt.

For more stubborn stains on the acoustic panel faces, create a mild soap and warm water solution.

Dampen a soft cloth in the solution and gently spot clean stained portions of the panel fabric.

Take special care not to oversaturate the material.

Let the panel fully air dry afterward before attempting repairs so that any moisture is completely evaporated.

Deeper stains may prove difficult to remove fully without harming the fabric.

It is up to your discretion whether to attempt their removal or simply cover them with new fabric.

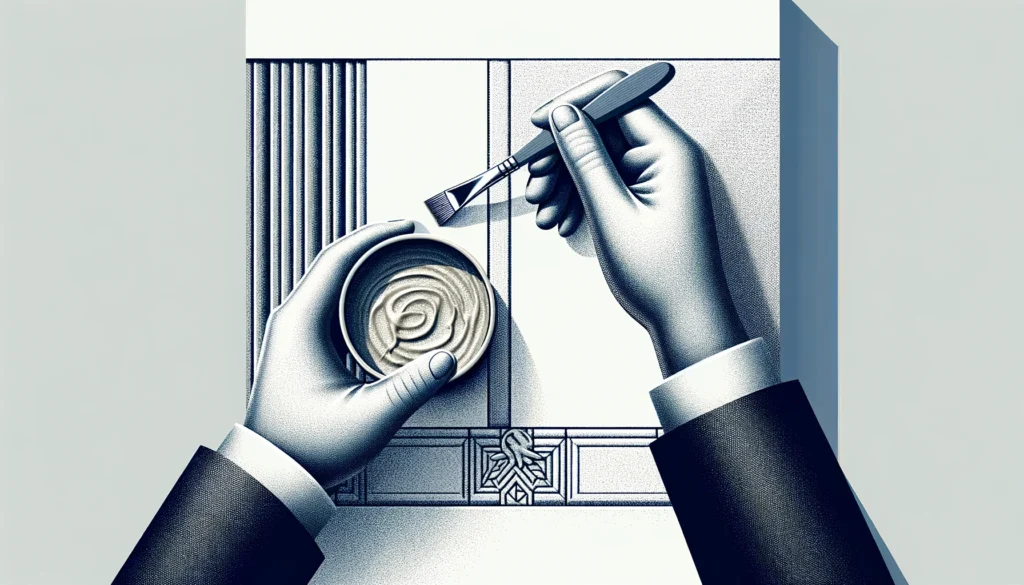

Make Any Structural Repairs

Before covering damaged acoustic panels with new fabric, it is important to make any necessary structural repairs for the best end results.

Warps, dents, cracks, or holes will still be obvious even under new covers if not properly filled and leveled.

Use acoustic panel specific fillers and compounds for best results.

Do a final inspection for any cracks, gaps, or holes needing filled on your acoustic panels.

Carefully follow product instructions and apply acoustic caulking, putties, or patch tape to fully seal openings and create a smooth surface.

Take care that connections between wall and panel edges have no gaps that compromise acoustic integrity using additional sealant to replace any aged, cracked, or missing previous sealant beads.

After application, give fillers time to fully cure rather than attempting to immediately cover and install newly patched panels.

This ensures an even, seamless surface for mounting the replacement fabric covers.

Lightly sand and wipe any uneven filler spots if necessary once dry.

Re-Cover the Fabric

With structural repairs complete and filler fully cured, you can move on to replacing the acoustic panel fabric covers.

It is easiest to remove all fabric first when fully re-covering rather than attempting patchwork repairs.

Use sharp scissors or a utility knife to carefully slice away from structural backs without damaging them.

Measure acoustic panels individually as each may differ in size slightly.

Cut replacement fabric for each leaving at least an extra inch of material extending past panel edges on all sides.

This excess can be wrapped around to the backside and creates a tighter cover surface.

Avoid overly stretching fabric as you adhere it.

Apply adhesive by spray or fabric glue brush evenly across central panel surfaces as well as all outer edges where the additional inch of material extends.

Contact cement spray allows stretching time for adjustment but provide ventilation when applying.

Ensure adhesive makes consistent contact rather than pooling due to uneven application.

Smooth replacement fabric over adhesive on the face being very careful to prevent creases, wrinkles, folds or overlap spots.

Work systematically from one end aligning edges as you smooth toward the opposite side.

Use a soft roller over the surface to press fabric firmly into the adhesive for a strong bond.

Install and Test

With new acoustic fabric coverings applied, panels must be reinstalled before testing their performance.

The most common mounting is directly to walls which may involve precisely patching previous holes or moving placement if old locations will still show damage like cracks not needing covered.

When possible, remount to studs for secure support.

Before patching previous mounting holes, test possible new arrangements first using small pieces of tape to temporarily hold panels where they exist.

Ensure new locations will allow panels to cover existing damage while providing optimal positioning and dispersion within the room space.

Only patch and create new proper reinforcement holes once a suitable location is verified.

Use acoustic sealant when remounting panels to fill any gaps between walls and edges for noise containment.

Avoid over-tightening screws or hardware as this can cause new damage over time as materials settle.

Check that panel faces hang evenly without bowing or lifting once installed.

Carefully test performance by generating sound at moderate volumes in the space before, during, and after repositioning panels.

Get multiple body positions and locations in the room during playback.

Listen closely for notable changes indicating panels are optimally absorbing key frequencies.

Make any slight adjustments to achieve the original level of acoustic management from your panels after repairs are made.

Conclusion

After thoroughly assessing damage, gathering materials, cleaning panels, conducting repairs, replacing fabric covers, and testing performance, your acoustic panels should now be restored to full functionality.

Carefully following this comprehensive process allows you to extend the lifecycle of acoustic panels through effective repairs rather than costly replacement.

Now your space can continue providing optimized sound absorption exactly where needed.