Imagine lying in your room, trying to focus on your work, but the constant noise from the bustling street outside keeps distracting you.

Or perhaps you’re in a home studio, attempting to record music, but the sounds from the next room are leaking into your microphones. Frustrating, isn’t it? This is where soundproof foam comes to the rescue.

While soundproof foam has been a go-to solution for various soundproofing needs, many people wonder if it’s effective in blocking sound from both directions—keeping external noise out while also containing the noise within.

This article aims to answer this critical question, shedding light on the functionalities, types, and effectiveness of soundproof foam, along with alternatives for those who may be looking for something different.

So, what sets soundproof foam apart from its often-confused cousin, acoustic foam? Let’s dive in to get your questions answered.

What Is Soundproof Foam?

One of the most persistent misunderstandings in the world of acoustics is the conflation of soundproof foam with acoustic foam. Although they may appear similar to the untrained eye, these materials serve distinct purposes.

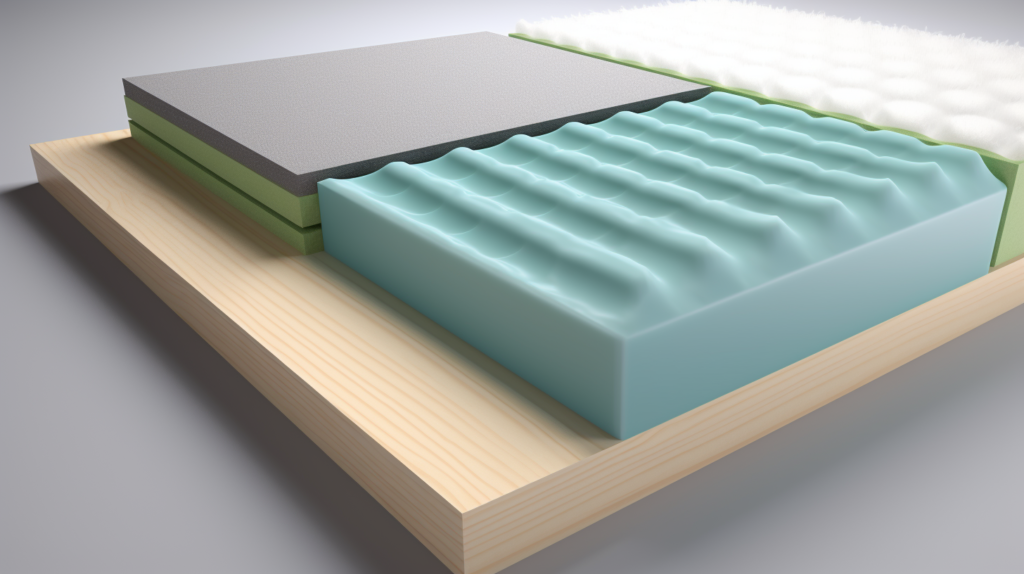

Acoustic foam, typically made from lighter materials like polyurethane, is designed to enhance the quality of sound within a space. It works by managing the internal reflections and echoes, thus improving the clarity of sounds within a room.

Soundproof foam, on the other hand, is a more robust material, designed with the primary goal of obstructing the passage of sound between different areas.

Traditionally made from mineral wool or fiberglass wool, soundproof foam acts as a formidable barrier that interrupts the flow of sound waves. It is this barrier property that allows it to serve its purpose of noise isolation between spaces.

Unlike acoustic foam, which is more concerned with the quality of sound within a space, soundproof foam focuses on keeping sound from moving from one space to another.

The materials used in the production of soundproof foam are specifically selected for their density and absorptive properties. Mineral wool, for instance, is derived from molten rock or industrial slag.

It has a high density, which allows it to effectively absorb and dissipate sound energy. Fiberglass wool, on the other hand, is spun from molten glass and, while lighter than mineral wool, still offers effective soundproofing capabilities.

Both of these materials are engineered to serve as barriers to sound transmission, each with its unique advantages and disadvantages.

How Does Soundproof Foam Work?

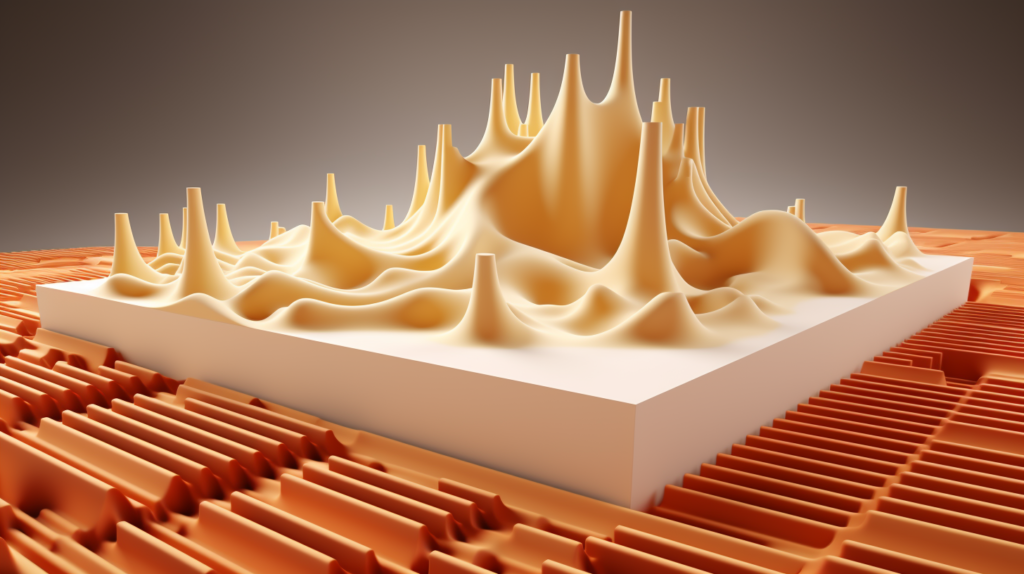

To fully appreciate how soundproof foam operates, it is essential to delve into the scientific principles that govern its effectiveness. Sound waves are essentially pressure waves that propagate through a medium, usually air.

When these waves encounter a surface or material, several things can happen: they can be reflected, absorbed, or transmitted. Soundproof foam aims to maximize absorption and minimize transmission.

The effectiveness of soundproof foam is governed by two main factors: density and thickness. Density relates to the compactness of the material.

A higher density means that there are more particles within a given volume, which increases the material’s ability to absorb sound waves.

As sound waves penetrate the dense material, they lose energy through friction and heat dissipation, reducing their amplitude and, consequently, the volume of the sound.

Thickness also plays a critical role in the foam’s ability to absorb sound. The thicker the foam, the more material the sound waves have to pass through, increasing the chances of them losing energy and getting absorbed.

Thickness is especially crucial when dealing with low-frequency sounds, which have longer wavelengths and require more material to be effectively absorbed.

Understanding these principles allows for more effective application of soundproof foam in various settings.

Whether you’re looking to soundproof a home studio, an industrial machine, or an office space, grasping the science of soundproofing will enable you to make informed choices about the type, density, and thickness of foam you’ll need.

Does Soundproof Foam Block Sound from Both Directions?

Soundproof foam’s directionality, or the question of whether it works both ways, is often the subject of debate among both experts and laypersons. To get to the heart of this matter, extensive research and a series of tests have been conducted.

The consensus is clear: soundproof foam does indeed work in both directions. It can both block external noise from entering a space and contain noise generated within a space from leaking out.

What sets soundproof foam apart is its inherent lack of a ‘front’ or ‘back.’ This is crucial because it means that the foam can be installed in any orientation and still function effectively.

This makes it incredibly versatile for a broad range of applications.

Whether you’re looking to soundproof a noisy restaurant kitchen from disrupting the dining area or need to contain the sound within a home theater, the bidirectional functionality of soundproof foam offers a reliable solution.

The orientation-agnostic nature of soundproof foam is one of its most compelling features, making it a preferred choice for many soundproofing applications.

From reducing the sound transmission between rooms in residential settings to blocking out industrial noise in manufacturing plants, the effectiveness of soundproof foam from both sides is a significant advantage.

What Are the Different Types of Soundproof Foam?

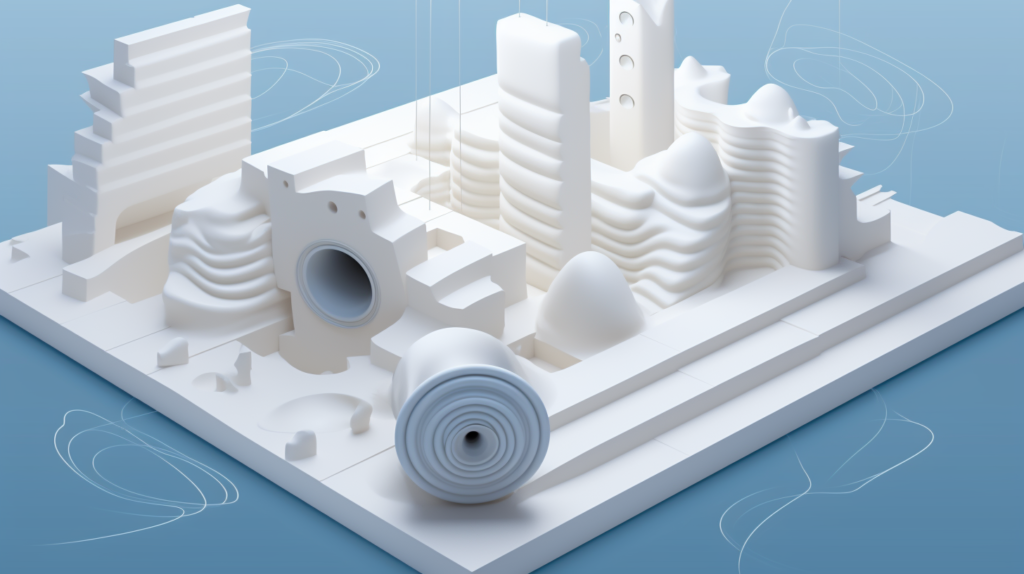

As you dig deeper into the world of soundproof foam, you’ll find that it’s not a one-size-fits-all solution. Different types of soundproof foam materials offer unique benefits.

The most common types of soundproof foam are made from mineral wool and fiberglass wool. Each of these materials has unique properties that make them more suitable for certain applications over others.

Mineral wool is highly valued for its fire-resistant properties. Created from molten rock or industrial waste, it is often utilized in settings where fire resistance is a crucial factor.

This makes it a popular choice for industrial applications where high temperatures are commonplace. Its density and ability to absorb sound also make it effective for soundproofing, but its fire-resistant properties often make it the go-to material for challenging environments.

Fiberglass wool, on the other hand, offers a different set of benefits. It is generally lighter than mineral wool and easier to handle, making it a preferred material for home-based or DIY projects.

While it may not offer the same level of fire resistance as mineral wool, it still provides effective soundproofing, especially for higher frequency sounds.

Both of these materials come in different densities and thicknesses, allowing for a high degree of customization based on specific needs.

Whether you are trying to soundproof a music studio or a noisy machine in an industrial setting, understanding the properties of these different materials can guide you in selecting the right type of soundproof foam.

What Factors Affect the Effectiveness of Soundproof Foam?

While soundproof foam is effective in its own right, there are several factors that can significantly impact its performance. The first of these is the density of the foam.

Simply put, denser foam is generally more effective at absorbing sound. This is because the tightly packed fibers or particles in the foam provide more resistance to the sound waves, causing them to dissipate faster.

The second important factor is the thickness of the foam. In scenarios where you are dealing with lower-frequency sounds, which are generally harder to block or absorb, a thicker layer of foam can be more effective.

The thickness adds an extra layer of material that the sound waves must pass through, reducing their energy even further.

The third factor that can influence the effectiveness of your soundproof foam is its placement. If the foam is not correctly installed or positioned, it can severely compromise its effectiveness.

For example, foam that is installed with gaps or not fitted tightly against surfaces can allow sound waves to pass through, reducing its sound-blocking capabilities.

Understanding these factors is crucial when planning a soundproofing project. From selecting the right type of foam to ensuring it is installed correctly, these factors can make or break your soundproofing efforts.

Installation Tips for Soundproof Foam

Proper installation of soundproof foam is not just a recommendation—it’s a necessity. Even the highest-quality, most suitable foam can fail to deliver if not installed correctly.

One of the first steps in installing soundproof foam is precise measurement. Accurate measurements are essential to ensure that the foam fits snugly within the designated space, whether it’s a wall, ceiling, or floor.

Any gaps or overlaps can compromise the effectiveness of the foam, allowing sound waves to leak through the imperfections.

The location where the foam will be installed is equally important. For example, soundproof foam is often placed between wall studs in residential buildings.

This ensures a seamless, continuous barrier that prevents the transmission of sound from either side. Similarly, in industrial settings, foam may be placed around machinery or equipment to minimize noise pollution.

The key is to identify the most effective placement to maximize sound absorption or blocking.

Securing the foam in place is another critical step in the installation process. Specialized adhesives designed for acoustic materials are often used to ensure that the foam adheres firmly to the surface.

Alternatively, mechanical fasteners like nails or screws can also be used, especially in settings where the foam needs to support additional weight or withstand external forces.

Whichever method is used, it’s crucial to ensure that the foam is securely fastened to prevent any movement or shifting, as this could create gaps that compromise its effectiveness.

Installation may also require specialized tools or equipment, particularly in large-scale or industrial projects. For example, large rolls of foam may require machinery to lift and place them accurately.

Even in smaller, DIY projects, tools like precision knives for cutting the foam or caulking guns for applying adhesive can make the installation process smoother and more effective.

What Are Some Effective Alternatives to Soundproof Foam?

While soundproof foam is an excellent option for many soundproofing applications, it’s not the only choice available. For those looking for alternatives, several other materials and solutions can offer effective soundproofing.

One such alternative is specialized soundproofing panels, like those offered by Burton Acoustix. These panels are made from a combination of rubber and felt and are designed to provide effective noise control.

They are particularly efficient at absorbing airborne noise and can also offer some degree of protection against structure-borne or impact noise.

Another option worth considering is polyester acoustic panels. These panels are made from synthetic fibers and offer a lightweight, versatile solution for soundproofing.

They are particularly effective at absorbing mid to high-frequency sounds and are easier to install than denser materials like mineral or fiberglass wool.

Polyester acoustic panels are suitable for a variety of settings, from residential and office spaces to larger commercial environments. They can be customized in various sizes and colors, offering both functional and aesthetic benefits.

Each of these alternatives has its own set of advantages and disadvantages, and the best choice will depend on the specific requirements of your project.

Whether it’s the type of noise you’re dealing with, the space where the material will be installed, or even budget considerations, understanding the pros and cons of each option can help you make an informed decision.

What Are the Pros and Cons of Alternative Soundproofing Materials?

While soundproof foam is undeniably effective, it’s essential to consider that alternative materials also have their own sets of advantages and disadvantages. Take, for example, rubber and felt panels, which excel in blocking airborne noise.

These materials are incredibly effective at reducing the transmission of voices, music, and other types of airborne sound. However, they may not be as effective against low-frequency noise, such as the rumbling from heavy machinery.

Additionally, these materials can be more expensive than traditional soundproof foam, making them potentially less suitable for budget-conscious projects.

Polyester acoustic panels offer another set of pros and cons. These panels are lightweight and easy to install, making them an excellent choice for individuals who prefer a more straightforward installation process.

They are also available in a variety of colors and designs, providing additional aesthetic options. However, they may not offer the same level of soundproofing as more dense materials like mineral wool or fiberglass wool.

Their lighter density makes them less effective at blocking low-frequency noises, which could be a limitation depending on your specific soundproofing needs.

Understanding the strengths and weaknesses of each material can help you make an informed decision that best suits your project.

Whether you’re dealing with high-frequency or low-frequency noise, have a small or large space, or are working with a limited or expansive budget, each material offers different benefits that could make it the ideal choice for your specific situation.

Conclusion

In closing, it’s clear that soundproof foam offers a versatile and effective solution for a wide range of soundproofing needs. And yes, it does work in both directions, making it a superb choice for projects that require blocking sound from both entering and exiting a space.

While there are alternative materials like rubber and felt panels or polyester acoustic panels, each comes with its own set of advantages and disadvantages.

Therefore, understanding your specific needs and how each material can meet those needs is essential for a successful soundproofing project.

The material you choose, whether it’s soundproof foam or an alternative, will be influenced by several factors. These include the type of noise you’re trying to control, the location where the material will be installed, and your budget.

By taking these factors into account, along with the specific advantages and disadvantages of each material, you can make an informed decision that will meet your soundproofing needs most effectively.