Is your home filled with unwanted noises that keep distracting you? Learning how to soundproof with drywall can help block irritating sounds.

Drywall provides useful sound dampening but works best when part of a multifaceted soundproofing system.

Let’s dive in to understand the acoustic properties, benefits, and limitations of using drywall for soundproofing.

What is Drywall?

Drywall, also known as gypsum board or sheetrock, is a common building material used for interior walls and ceilings.

It consists of a layer of gypsum plaster sandwiched between two thick sheets of paper.

Drywall is a lightweight and easy to install option for constructing interior partitions in homes and commercial buildings.

The gypsum core of drywall has natural sound absorbing properties while the heavy paper covering blocks sound transmission.

This makes drywall a popular choice when building new walls and ceilings. However, drywall by itself has limits in its ability to dampen sound.

Drywall panels are available in various sizes and thicknesses. The most common size is four feet by eight feet and half an inch thick.

Thicker drywall panels provide more mass which improves soundproofing. Drywall sheets are installed by screwing or nailing them to wood or metal wall studs and ceiling joists.

The seams between panels are covered with tape and joint compound to create a smooth continuous surface ready for priming and painting.

Drywall provides a cost-effective way to finish interior spaces compared to more labor intensive traditional plaster walls.

It allows for easy access to utilities since panels can be cut out and replaced as needed.

Overall, drywall is a versatile and affordable wall and ceiling covering used in many residential and commercial buildings today.

So Is Drywall Good For Soundproofing?

Yes, drywall can be considered good for soundproofing because it adds mass to walls and ceilings. The extra layer of gypsum and heavy paper provides more density compared to just wood or metal studs alone.

This added mass impedes the transmission of noise through building structures. Drywall by itself offers a basic level of sound absorption and blocking.

However, drywall performs better for soundproofing purposes when combined with other materials and techniques.

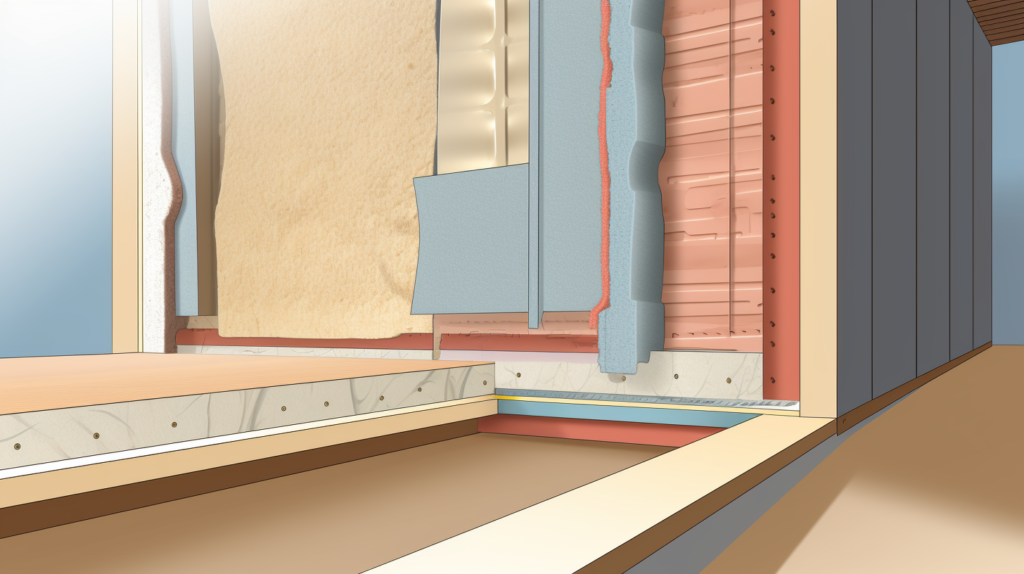

Filling wall cavities with insulation adds absorption and damping. Resilient channels decouple the drywall from the studs to further isolate noise.

Multiple staggered layers of drywall increases mass and eliminates direct sound paths. While drywall alone has acoustic benefits, it works best as part of a system with other soundproofing methods.

But the noise reduction provided by drywall is better than no separation at all between rooms or floors.

Pros of Using Drywall for Soundproofing

There are some benefits to using basic drywall for soundproofing purposes. Drywall does provide more sound absorption and sound blocking than just having an open wall with no separation between rooms.

While drywall alone does not block most noises, it does dampen sounds more than nothing at all. Drywall is also one of the most affordable wall building materials.

It is far cheaper than many other specialized soundproofing products. The reasonable cost makes drywall a good option for do-it-yourselfers as well as contractors trying to work within limited budgets.

Another advantage of drywall is that it can be installed by most homeowners and professional contractors.

Drywall installation only requires some basic tools and materials like a screw gun, screws, tape, and joint compound.

The lightweight panels are relatively easy to hang on wall studs and ceilings joists compared to other soundproofing materials.

While some specialized soundproofing products require professional installation, anyone comfortable with basic drywall finishing can handle installing and finishing standard drywall.

This allows homeowners to use drywall for small soundproofing projects without the added cost of hiring contractors.

The ease of installation also keeps labor costs down on large drywall soundproofing jobs.

In situations where budget and labor are limited, drywall may be the most realistic option for attempting to reduce noise transmission between rooms.

While it does not provide the highest level of sound blocking, drywall does improve acoustic separation more than wood or metal stud walls alone.

The noise reduction from drywall can be adequate for some projects depending on the specific noise sources and privacy needs.

In cases where specialized soundproofing is not feasible, drywall may provide a “better than nothing” improvement.

Cons of Using Only Drywall for Soundproofing

While drywall can dampen sounds more than open walls, using only drywall has significant limitations for effective soundproofing. Drywall by itself does not block most noises, especially lower frequencies.

Even a few layers of standard drywall will still allow a fair amount of sound transmission. Noises like voices or music are readily audible through drywall walls.

Another issue is that any small cracks, gaps, or incomplete sealing around edges, electrical boxes, or vents will severely compromise acoustic performance. These weaknesses allow sounds paths to leak through.

The hollow inner cavity bounded by drywall also allows noise to reverberate within the wall.

There are minimal internal sound absorbing materials when drywall is installed directly against the wood or metal studs.

Sound waves reflect back and forth between the drywall surfaces. This reverberation reduces sound blocking effectiveness compared to materials like insulation that absorb sound.

Most noise blocking requires combining drywall with insulation or other absorbent materials to dampen reverberation and dissipate sound energy.

For the highest levels of soundproofing, relying solely on drywall will not be sufficient. Multiple layers helps improve performance but still has limits.

Specialized soundproofing drywall or doubling up standard drywall provides much more mass which impedes noise transmission.

But the hollow wall cavities allow flanking around the drywall unless they are filled with insulation.

The primary downside to drywall-only soundproofing is that it allows too much audible noise transmission for many applications where privacy or noise control are needed.

How to Improve Drywall’s Soundproofing Ability

There are methods to enhance regular drywall’s ability to reduce noise transmission. A common technique is to use multiple layers of drywall panels with the seams offset between layers.

Staggering the joints eliminates seams that align and provide direct sound leakage paths.

Two or three layers of drywall with offset seams provides substantially more mass to impede noise while also damping resonance within the wall cavity.

However, there will still be noise flanking unless insulation is also added.

Installing thick, dense insulation like rockwool or denim fiberglass batts in the wall cavity greatly improves performance.

The insulation absorbs sound reverberation and dissipates the energy so less noise transmits through.

Acoustic caulk applied around the perimeter edges of the drywall layers seals small cracks and gaps that compromise soundproofing.

Careful sealing eliminates potential sound leaks. Combining drywall with insulation, sealants, and techniques like resilient channels or staggered studs creates an effective sound blocking wall system.

Specialized soundproofing drywall like QuietRock is also available. These panels contain viscoelastic polymers or damped constrained layer cores that help dissipate sound energy.

One or two layers of soundproof drywall can achieve STC ratings over 50. However, these specialty panels are more expensive than regular drywall.

Homeowners may also consider applying mass loaded vinyl or limp soundproofing materials to further dampen noise.

In some cases, drywall can be combined with other sound-absorbing materials like insulation, sealants, green glue, carpets, and acoustic tiles to create an effective noise barrier without needing expensive purpose-made acoustical drywall products.

When Drywall Alone Is Sufficient

For some basic soundproofing between rooms, using regular drywall alone may suffice.

In a bedroom or media room where minimal noise blocking is needed, single drywall layers may provide adequate separation from hallways or adjacent living spaces.

Drywall by itself also helps when the goal is mainly to dampen voices or medium volume sounds.

The noise reduction from standard drywall could work for creating quiet offices next to customer service call centers.

Likewise, drywall alone may suffice for blocking noise from a laundry room to an adjacent family room.

Home theaters with surround sound systems may benefit from drywall alone if it is combined with other measures like carpets, acoustic panels, and keeping speakers away from shared walls.

For studio apartments or basement remodels where budget is limited, drywall may be the only affordable choice to reduce noise transmitted to other units.

In these cases, high performance soundproofing would be ideal but standard drywall can still improve the situation within budget constraints.

For new construction projects using staggered studs or resilient channels, drywall may adequately block noises when installed properly.

Overall drywall alone can be sufficient depending on the specific noise sources, privacy needs, and budget limitations of a project.

In optimal applications, it can improve acoustic separation enough to serve its purpose.

Conclusion

In summary, drywall is good for soundproofing but can only help basic sound dampening but has limitations for blocking loud noises.

While drywall alone offers some acoustic benefits, it works best when combined with insulation, sealants, extra layers, and specialized materials as part of a comprehensive soundproofing system.

With careful installation and supplemental treatments, drywall can become an effective component in reducing noise transmission. But relying solely on drywall will likely be insufficient for high levels of soundproofing required in many residential and commercial settings.