Struggling with noise transfer between rooms? Mineral wool could be the soundproofing solution you need.

Mineral wool is an excellent insulating material for soundproofing because its fibrous structure absorbs sound and its density blocks noise transmission.

Let’s dive in to see how mineral wool performs as a soundproofing material and how to properly install it for optimal noise reduction.

What is Mineral Wool?

Mineral wool refers to fibrous materials that are formed by spinning molten mineral or rock materials into fine fibers.

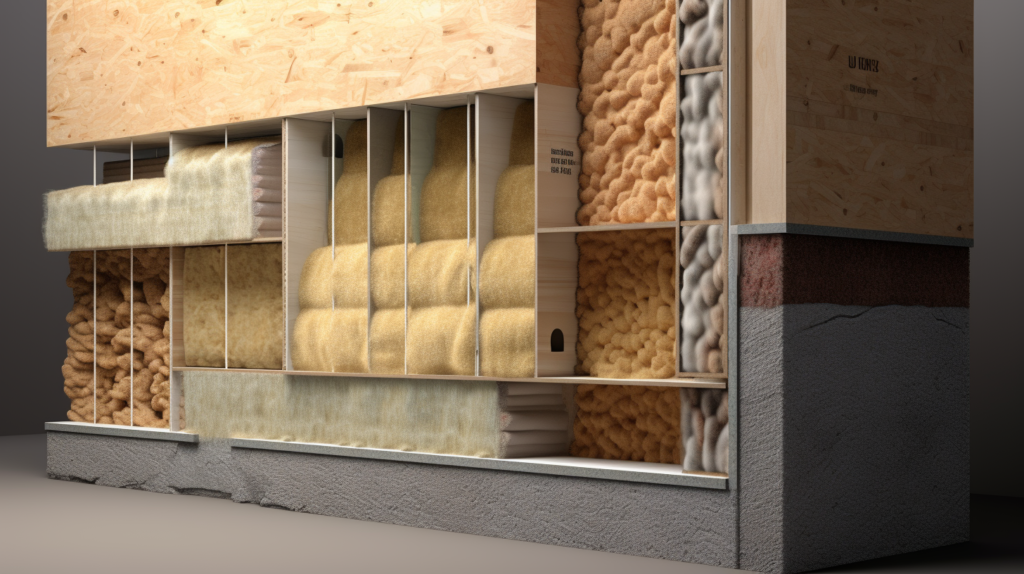

There are two main types of mineral wool used for insulation and soundproofing applications: stone wool and slag wool.

Stone wool, also known as rock wool, is made from natural basalt rock or diabase. The rock is melted at temperatures over 2700°F and spun into fibers.

Slag wool, on the other hand, is made from blast furnace slag, a byproduct of steel production. The slag is melted and spun into fibers in a similar way to stone wool.

The end product of both types of mineral wool is a mass of fine, intertwined fibers that form an effective insulating and sound absorbing material.

Mineral wool has some common characteristics that make it useful for soundproofing. First, it is non-combustible and fire-resistant.

The high melting points of the original molten rock and slag materials translate into a high degree of fire resistance for mineral wool.

When exposed to heat or flame, mineral wool does not ignite or sustain combustion. This makes it very safe for use in building and construction applications.

Mineral wool is also resistant to corrosion and degradation over time.

Unlike some other insulating materials, it will not rot or decompose, and its thermal and acoustical properties remain consistent over decades.

Is Mineral Wool Good for Soundproofing?

Yes, mineral wool is an excellent material for soundproofing. It has a combination of properties that make it very effective at reducing sound transmission.

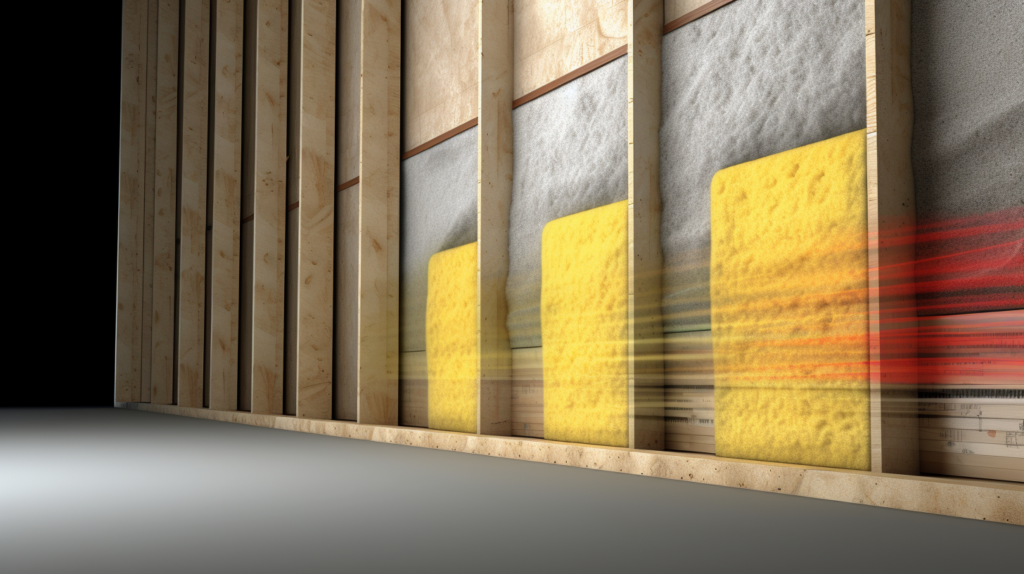

The main reasons mineral wool performs well acoustically are its porous fibrous structure and its density.

The multitude of fine, intertwined fibers in mineral wool act as countless tiny baffles that absorb and dissipate sound energy rather than reflecting it.

This absorption prevents sound waves from continuing to travel through the material.

In addition, mineral wool provides mass which serves to block sound transmission. The more dense and heavy the material, the harder it is for sound waves to pass through.

Mineral wool is produced in densities from 1 to 6 pounds per cubic foot, giving it the heft needed to impede sound.

The absorption and mass blocking capabilities of mineral wool combine to significantly reduce the transmission of airborne noise.

For these reasons, mineral wool insulation is regarded as one of the best options for interior soundproofing projects.

It is far superior to less dense, lighter materials such as fiberglass when it comes to its sound dampening abilities.

Benefits of Using Mineral Wool for Soundproofing

There are several specific benefits that make mineral wool insulation advantageous for soundproofing applications:

Effective Sound Absorption

The porous fibrous structure of mineral wool absorbs sound rather than allowing it to reflect off surfaces.

This helps diminish echo and reverberation that can amplify noise in enclosed spaces. The fiber structure converts acoustic energy into barely detectable heat as sound passes through the material.

This results in excellent damping of noise.

Density Blocks Sound Transmission

Mineral wool provides mass loaded barriers that impede the transmission of noise through building structures.

The density of the insulation helps block sounds from transferring to adjoining spaces. Thicker, denser layers of mineral wool are optimal for blocking lower frequency noise.

Does Not Degrade Over Time

Unlike some other insulating materials, mineral wool retains its acoustical performance over many decades. It will not break down or rot away with age.

Properly installed mineral wool maintains its sound dampening abilities as long as it is in place. This durability makes it a smart long-term investment for soundproofing.

Resists Mold and Mildew

Mineral wool fibers do not support mold or mildew growth. This prevents any degradation of performance that can result from microbial colonization within the material.

Wet mineral wool insulation retains its acoustic properties once dried out. Mold growth will not damage the material or diminish its sound absorption.

Available in Variety of Thicknesses

Mineral wool soundproofing products come in thicknesses ranging from just an inch or two up to multiple inches thick.

Thicker products can be used when maximum noise blocking is needed. Custom thicknesses can be built up by layering multiple panels of insulation.

This versatility allows mineral wool to meet the specific needs of each application.

Affordable Cost

Compared to less effective materials like fiberglass or foams, mineral wool represents a very cost-effective solution for enhancing soundproofing.

It provides substantial noise reduction at a moderate price point. Mineral wool insulation offers very good value in terms of its acoustic performance per dollar.

How to Install Mineral Wool for Soundproofing

When using mineral wool for soundproofing, proper installation is key to achieving optimal performance. Here are some best practices to follow:

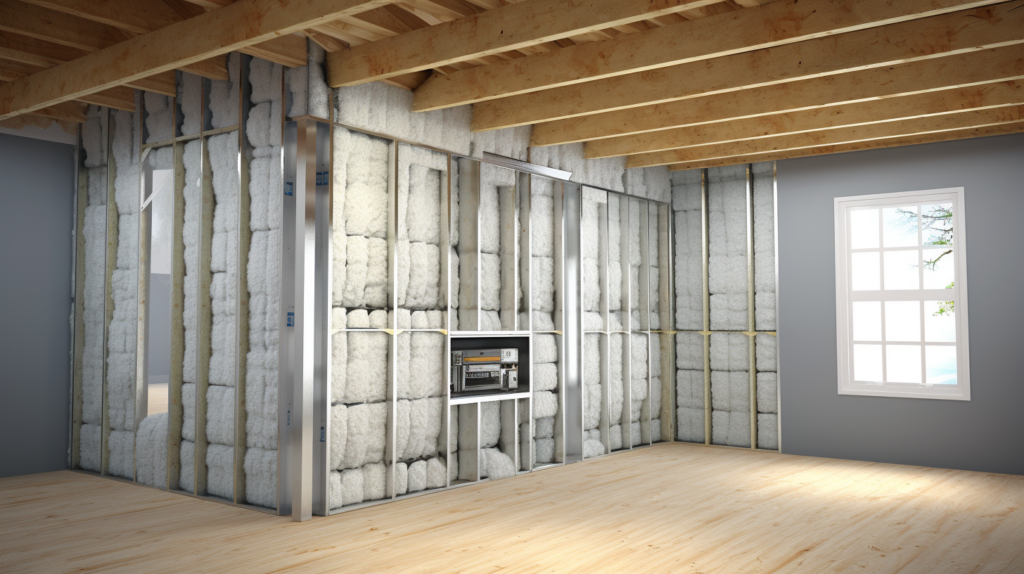

Use in Walls, Ceilings, Floors

Mineral wool insulation can be installed in all types of enclosed framing spaces. It is highly effective when placed in the cavities of interior and partition walls.

The insulation decreases sound transmission through the framing from one room to another. For floors, mineral wool underlayment helps dampen impact noises like footsteps.

Overhead installations between ceiling joists absorb indoor sounds reflecting off the ceiling.

Cut to Fit Snugly

For best results, mineral wool insulation should fit snugly into framing cavities without gaps or compression. The material can be cut with a serrated knife to achieve custom fits.

Take care when handling and cutting mineral wool to minimize dust. Wear safety goggles, gloves, long sleeves and an N95 respirator mask.

Layer Between Drywall

Layering a thicker mineral wool product between two layers of drywall can significantly improve sound isolation. Staggering the drywall seams also helps reduce noise leakage.

Apply acoustic caulk between the insulation and framing to seal air gaps before installing the second layer of drywall.

Performance as a Soundproofing Material

When installed correctly, mineral wool delivers exceptional noise reduction and sound damping:

Reduces Airborne Noise Transmission

One of the biggest benefits of using mineral wool for soundproofing is its ability to decrease the transmission of airborne noise between rooms or multi-unit dwellings. Its noise absorption and barrier properties make mineral wool far superior to fiberglass for reducing noise transfer.

Effective at Blocking Lower Frequencies

With increased thickness and density, mineral wool is very effective at blocking lower frequency noises like voices, music and motors.

These types of sounds are harder to attenuate. Stopping their transmission requires the mass and absorption that mineral wool provides.

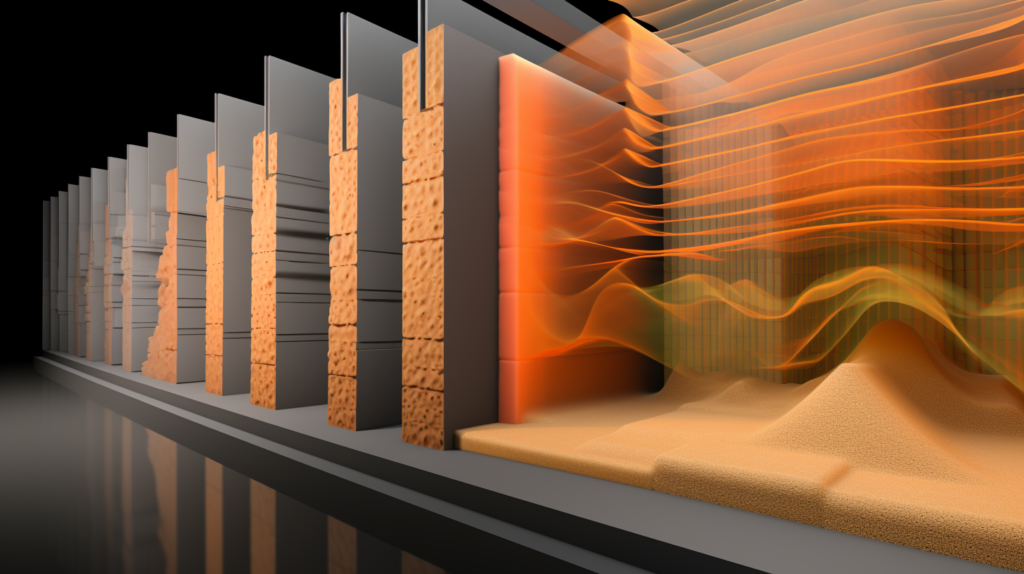

Density and Thickness Impact Performance

Mineral wool products with higher density and more thickness will block more noise.

For instance, a 2” thick, 4-6 lb/cu ft density mineral wool batt will isolate more sound than a 1” thick, 1-2 lb/cu ft batt. Matching the specs to the specific noise reduction requirements is necessary.

Layering Improves Performance

Using multiple layers of mineral wool with staggered seams boosts sound isolation abilities. Combing mineral wool batts or boards with acoustical mats or caulks improves performance. Layering also allows for increased thickness when very high noise blocking capability is needed.

Considerations When Using Mineral Wool

While very effective for soundproofing, there are a few factors to keep in mind when working with mineral wool insulation:

Dust Requires Safety Precautions

When mineral wool is cut or handled, dust particles can be released into the air. Always wear an N95 mask and ventilate the area. The small fibers in mineral wool dust can be inhaled or irritate the eyes and skin, so take protective measures.

Skin and Eye Irritant

Loose fibers may cause temporary skin itching or eye irritation if proper long sleeves, gloves and eye protection are not used. Thoroughly rinse any skin or eye contact with water to alleviate irritation. Wearing protective gear prevents this.

Less Rigid Than Fiberglass

Mineral wool insulation materials are flexible and compressible compared to rigid fiberglass boards. For some applications like insulating ductwork, rigid boards provide better fit and performance.

Can Be Compressed and Lose Effectiveness

If mineral wool is installed too tightly into framing spaces, its thickness and density may be reduced. This compression decreases sound blocking capacity. A snug but not too tight fit is best.

May Require Additional Fire Protection

Some local building codes have additional requirements regarding fire rated assemblies when using mineral wool. Be sure to consult local codes and include any required topping or coating materials.

Conclusion

Mineral wool insulation provides an affordable, high-performing solution for soundproofing projects. Its fibrous structure absorbs noise while its density blocks sound transmission.

Following proper installation methods and safety precautions allows mineral wool to effectively reduce noise transfer between rooms.

For optimal acoustic isolation, layering mineral wool with other sound-blocking materials is recommended.

With the right thickness and density, mineral wool can significantly dampen both airborne noise and lower frequency sounds.