Do your chickens cluck up a racket that drives you and your neighbors nuts? A soundproof chicken coop can solve the problem, providing peace for all.

Building a soundproof chicken coop requires strategic planning, quality materials, and meticulous construction to effectively block noise.

Let’s dive into a step-by-step guide on how to build a soundproof chicken coop from start to finish.

Step 1. Choose The Right Location for Your Soundproof Chicken Coop

When starting your project to build a soundproof chicken coop, the first important decision is choosing an appropriate location. You’ll want to pick a spot that is situated away from any neighbors, as even a well-soundproofed coop can still emit some level of noise.

Try to position the coop as far from other homes as possible, and avoid locations that would funnel sound towards populated areas.

The ideal location for a soundproof chicken coop is tucked away in a corner of your property where surrounding buildings or landscaping can help provide acoustic barriers. Take note of which directions noise may travel and try to orient the coop accordingly.

Face windows and doors towards wooded areas, storage sheds, or other acceptable sound barriers instead of towards your own home.

You’ll also want to select a site with proper sun exposure and drainage. Make sure your coop will receive ample daylight and fresh air flow.

The ground should not puddle easily, but have enough slope for drainage. Consider positioning the coop under shade trees to help keep it cool in summer.

Just be sure falling leaves won’t clog drainage.

Spend time surveying your property to find the optimum spot that balances sound privacy, sunlight, and drainage for an ideal chicken coop location. This will provide the necessary foundation for building an effective sound barrier for your flock.

Step 2: Construct a Sturdy Frame For The Chicken Coop

Once you’ve identified the perfect site, construction on your soundproof coop can begin! The first step is building a sturdy wooden frame that will serve as the support structure.

Use exterior grade lumber such as 2×4 or 2×6 boards and build a robust frame anchored securely to the ground. Ensure there are no gaps between the framing boards by cutting pieces precisely or using caulk to seal cracks.

Gaps in the frame will compromise sound blocking, so take care to construct an airtight, robust frame.

Consider framing a dual layer wall with staggered studs for improved sound isolation. You can also use specialized sound blocking panels like mass loaded vinyl sandwiched between walls.

Build the frame with thicker boards, cross bracing, and ample fasteners to make it sturdy enough to hold insulation and interior wall surfaces.

Do not skimp on the frame just because it will be hidden behind walls. A well-constructed frame is crucial for keeping exterior noise out of your coop.

Pay close attention to detail when assembling the shell of your soundproof structure.

Step 3: Install Insulation for Noise Control

Once the outer frame of your coop is securely in place, it’s time to start insulating. Proper insulation is key for an effective sound barrier.

Use fibrous insulation like fiberglass batts, rockwool, or recycled denim fill. The insulation should have a high NRC (noise reduction coefficient) rating.

Completely pack insulation into every crack and cavity between wall studs and ceiling joists. Do not leave any gaps.

Fill every square inch of your frame with tightly packed batt insulation for maximum noise blocking. Use sound sealing caulk around edges to hold insulation in place.

You can also use spray foam insulation for increased density. Apply several inches of closed cell spray foam between framing in addition to traditional batts.

The more insulation you can pack in, the better the sound dampening will be. This will help muffle noises like clucking and flap their wings against the coop walls at night.

Install insulation beneath the floor as well. Use rockwool or foam boards under the foundation to prevent noise transfer through the ground.

Your insulation job should create a completely sealed acoustic barrier around the entire coop interior.

Step 4: Install Interior Walls and Surfaces

With a well-insulated frame, you’re ready to install interior wall surfaces. Use plywood, drywall, MDF panels or similar solid materials.

Avoid chicken wire or fabric surfaces that will allow sound to pass through. Secure panels tightly against framing with screws or construction adhesive to seal edges.

To reduce echoes inside the coop, consider lining walls and ceilings with acoustic foam panels or fiberglass boards. You can also hang acoustic blankets as an attractive method of absorbing sound. Avoid leaving large bare hard surfaces wherever possible.

Install interior walls by cutting panels to overlap framing, then caulk edges for an air tight seal. Look for any cracks or holes as you work and fill them with caulk or spray foam.

The interior should be completely sealed with no openings for sound to penetrate.

Step 5: Check Exterior For openings

Ensure exterior frame is installed without any openings. Caulk around edges and seal every seam. Use adhesive, overlapping joints, and plenty of fasteners to create an impenetrable sound shell.

The exterior should be devoid of gaps where noise might sneak through.

Consider using laminated mass loaded vinyl sheets under the exterior siding for added density.

Step 6: Create Windows, Doors, and Openings

For any doors, windows, and other openings, special care must be taken to dampen noise. These will likely be the weakest points in your soundproofing efforts if not properly addressed.

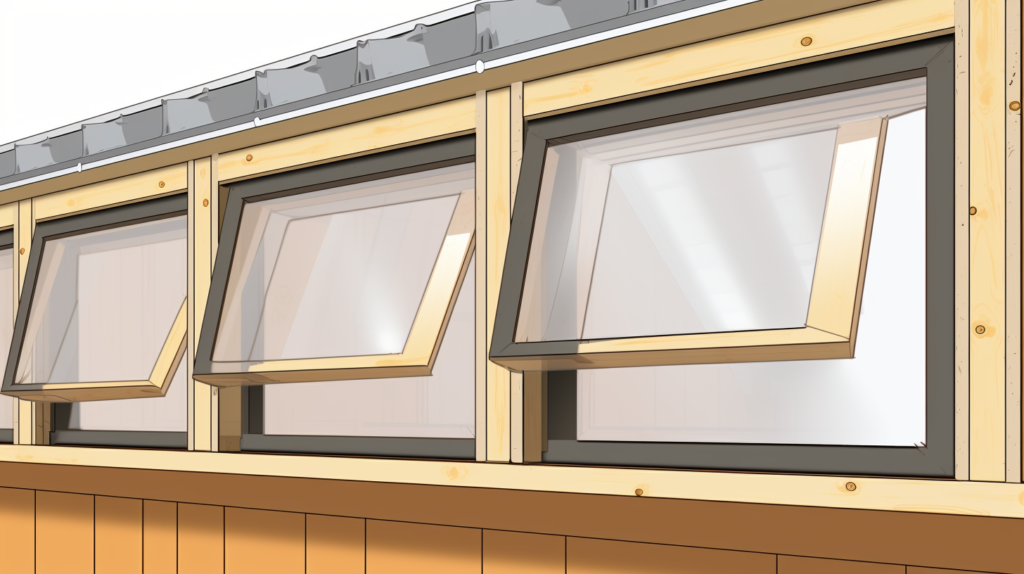

Position any windows to face away from noise sensitive areas, towards woods, landscaping, or acceptable sound zones. For windows, use sealed dual pane glass, small sizes, and non-opening panes if possible.

To shed rain, angle windows upwards to avoid drips over sound leaks.

Doors should seal tightly against jambs and threshold with a good weather seal and bottom sweep. Consider adding a vestibule entryway to prevent sound escaping each time the door opens.

Any vents, chimneys, and other openings also need sealing. Cover exterior vents with acoustical register covers to allow airflow while reducing noise.

Use rubber gaskets behind attic vents and seal with foam. Any gaps compromise soundproofing, so methodically seal the entire coop envelope.

Step 7: Inspect for Sound Leaks

Once your coop construction is complete, do a careful final inspection to identify and fix any remaining sound leaks or gaps in the structure. Go inside the coop and have an assistant make noise around the exterior, then listen closely for any areas that leak noise.

Use acoustic sealant or caulk to plug any holes or cracks that emerge during this testing process. You may need to apply new weather stripping, adjust door seals, or add insulation in overlooked areas.

Keep testing and sealing until the coop interior is as close to completely soundproof as possible.

Regularly check your coop for developing leaks, cracks, or gaps that can compromise sound blocking. Catching issues early allows for quick fixes before major soundproofing repairs become necessary.

Step 8: Check For Ventilation Of Chicken Coop

Proper ventilation is essential for a healthy flock, so be sure to incorporate adjustable vents and windows in your coop design. Start by leaving openings fully open to promote maximum airflow, then partially close them incrementally if noise becomes an issue.

Small slot windows hinged at top work great, as you can control airflow while sound remains aimed upwards. Use windows with interior baffles or insulation to muffle outside noise entering vents.

Make sure air can flow freely through the coop interior by leaving a pathway unobstructed by absorption panels or furniture.

Monitor ammonia levels by scent and use the minimum venting required. Be prepared to add inline fans if the heat becomes excessive. Place fans inside insulated ducting or sound-dampening boxes to minimize noise.

With careful ventilation planning, you can properly cool and freshen your coop air without amplifying sound.

Conclusion

Building a soundproof chicken coop requires careful planning, quality materials, and meticulous construction to maintain noise control. Follow these guidelines to create a peaceful environment free of exterior clucks and squawks.

With robust framing, ample insulation, strategic ventilation, and acoustic treatments, your chickens can roost quietly and your neighbors will be none the wiser!