If you’re wondering if you can buy cork for soundproofing and how thick it should actually be, it’s important not to follow the dubious 3mm recommendation floating around.

While cork can be purchased in sheets and tiles for acoustic applications, it needs to be much thicker than 3mm to have any meaningful noise blocking effect.

The key is that effective soundproofing requires mass to literally stop sound waves from transmitting. Thin cork can only absorb slightly.

Let’s dive into what thickness and materials really deliver proper acoustic insulation and noise control.

What Thickness of Cork is Commonly Recommended for Soundproofing?

Across the internet, including informational sites, forum discussions, video tutorials, and product listings, a very common claim is made that cork only needs to be 3mm thick in order to effectively soundproof a room.

At first glance, recommending 3mm cork sheets makes sense based on the fact that cork as a material has intrinsically good sound dampening properties.

Placing a thin layer of cork over a wall, ceiling or floor will provide some measurable amount of noise reduction.

The sound absorbing nature of cork means the material can soak up some of the sound energy through vibration damping.

When sound hits the cork, the vibrations causing the noise get diffused as the energy is converted into heat energy in the cork.

This does mean that minimal 3mm cork sheeting can provide a basic level of damping for noise control.

However, despite the claims of many sources, while 3mm cork may provide minor sound damping, this ultra-thin layer alone is nowhere near sufficient for achieving proper, effective soundproofing of loud external noises.

Damping only goes so far, and fails when heavier mass is needed to fully block sound waves from transmitting from one space to another. This distinction is where simply repeating the insufficient 3mm recommendation falls short.

True soundproofing relies heavily on using dense mass to fully prevent noise vibrations from penetrating through walls and floors.

The pervasive 3mm thickness values stems from an over-reliance on the basic damping properties of cork.

In reality, only considering absorption fails to acknowledge the physics of how lower frequencies behave and the need for thick, heavy blocking to stop these sounds.

For full, broadband sound insulation, absorption alone does not cut it. The 3mm suggestion is misguided, as it treats soundproofing as mainly needing absorption, when heavy mass is critical.

Simply put, despite many sources stating otherwise, effective soundproofing requires much thicker and higher density materials than 3mm cork sheets in order to properly block audible sound waves from transmitting between spaces.

While suitable for basic damping, 3mm cork lacks the mass needed for proper acoustic insulation against loud noises, music, voices, etc. For real soundproofing, more than just absorption is required.

Why Does Soundproofing Require Mass?

To understand why the oft-repeated 3mm cork recommendation fall short for soundproofing, one must consider how soundproofing actually works.

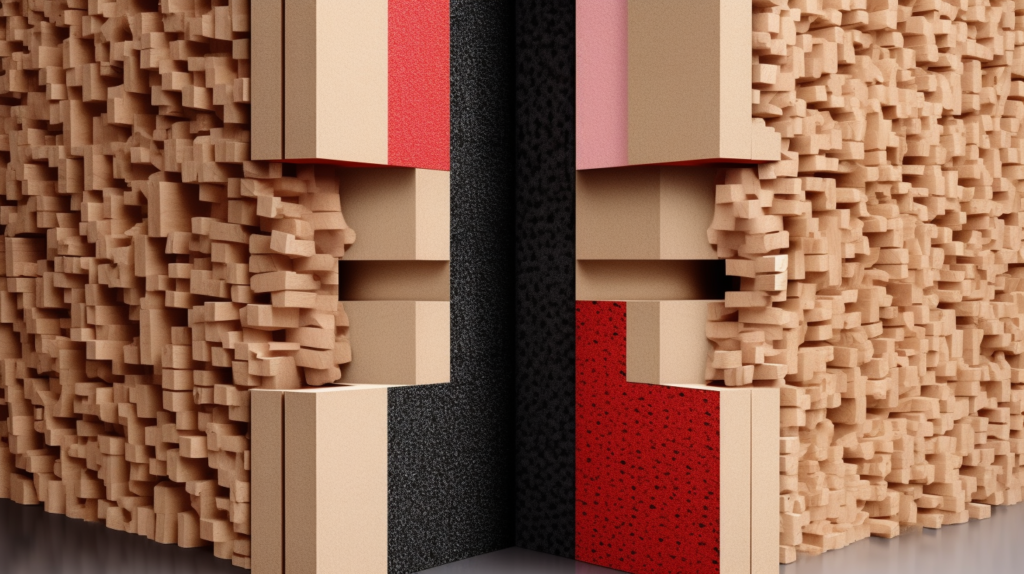

Rather than just absorbing vibrations, true acoustic insulation relies on using mass to fully block audible sound waves from transmitting from one room to another adjacent space.

High density materials form a barrier preventing noise vibrations from penetrating through floors and walls to preserve quietness on the other side.

The core physics of optimal soundproofing involves leveraging thick, heavy materials to literally halt the passage of noise from a source to the listener in another room.

The dense mass absorbs the sound energy while also stopping the vibrations themselves from propagating through the structure.

Without sufficient mass, noise will easily travel from room to room, even if some absorption is present.

The more mass placed between a noise source and the adjacent space, the more effective the soundproofing will be.

Thick heavy materials can fully block sound waves, while thin absorbers alone allow significant transmission.

Also, lower frequencies inherently require more mass to block based on their longer sound wave properties.

For full acoustic insulation across the frequency range, both absorption AND high mass are required.

Just relying on the light sound absorption of 3mm cork is faulty, as mid and high frequencies get absorbed but still readily transmit vibrations through the thin material.

Lower frequencies easily penetrate through with little impedance. Heavy mass is essential to halt this vibration transmission, absorbing the energy while the thickness blocks travel through.

Lacking mass, 3mm cork performs very poorly when it comes to insulating impact noise, music, voices, appliances, etc. from adjacent spaces.

In summary, for a room to be properly soundproofed from external noise sources, high mass blocking is absolutely necessary for effective acoustic insulation across the entire audible frequency range.

Using just thin absorbers recommended by many sources simply does not provide comprehensive soundproofing. Both high mass and absorption together are vital.

How Thick Should Cork Be for Effective Soundproofing?

Given the physics requiring both dense mass and absorptive properties, what thickness is appropriate for true, heavy-duty soundproofing?

For noticeably reducing loud sounds across the full frequency spectrum, using dedicated soundproofing panels made from inherently dense materials is recommended.

Materials like mass loaded vinyl, rubber, and thick mineral wool provide excellent noise blocking thanks to their high mass properties.

Specifically, soundproofing panels made using mass loaded vinyl or dense rubber materials work incredibly well to halt noise transmission.

These materials are designed for maximum density to block vibrations, commonly loaded with heavy metals to increase weight.

Alternately, thick mineral wool or fiberglass panels at 3 lb/ft3 density or higher create sufficient mass.

These types of heavy, dense panels supply the required mass to effectively block lower frequency sounds from penetrating through walls and floors.

With proper thickness, they prevent noise transmission much better than flimsy 3mm cork ever could.

Generally the thicker the material, the better the soundproofing performance since more mass is present to absorb and halt vibration.

25mm dense soundproofing panels will block mid and high frequencies well, but 50mm, 75mm or greater thickness is ideal for stopping deeper bass and rumble noises.

For reference, standard 5 lb/ft3 mineral wool panels 25mm thick will work decently but 50mm+ is better for low frequencies. Mass loaded vinyl achieves effective blocking at 25mm thickness or more thanks to the ultra-high built-in density.

For serious soundproofing against loud noises, panels should be a minimum of 25mm to 50mm thick, using materials specifically designed for density and mass. With appropriate thick, heavy panels, noise from adjacent rooms or outside can be significantly reduced. Don’t rely on inadequate 3mm cork when you need proven soundproofing capability.

How Thick Should Cork Be for Effective Acoustic Treatment?

Thus far we’ve focused on using mass to block sound transmission from space to space. A different acoustic goal is treating sound problems within a room by absorbing echoes and reverberation.

Here the aim is controlling excess reflections that create an unpleasant boomy sound in the space.

For acoustic treatment via absorption, noise damping materials should still be 25mm thick or more for adequate mid-high frequency sound absorption.

Just like with insulation between spaces, insufficient material thickness hampers the ability to effectively absorb problematic room reflections.

Greater depth is needed to catch sound waves before they bounce off hard surfaces like drywall and tile.

25mm+ thickness provides enough depth for the high frequencies causing echoes to penetrate into absorptive materials and be dissipated, rather than bounce around the room.

Polyester fiber acoustic panels around 25mm thickness are a popular choice since they are lightweight yet provide effective mid-high frequency absorption without needing to be as thick as denser mineral wool or fiberglass.

Alternatively, 50mm thick standard fiberglass or rockwool panels offer excellent sound absorption across an extended range from voices up through high pitches.

The key point is that 3mm of cork is nowhere near sufficient for acoustic panel thickness, regardless of the material used.

Thin panels fail to provide adequate diffusion depth for sounds to enter the material, limiting acoustic treatment capability.

For properly controlling room echo issues, thicker 25mm+ panels are recommended to absorb, diffuse, and deaden unwanted reflections.

What Are Good Alternatives to Cork for Acoustic Treatment?

Given the superior acoustic properties of thicker, porous absorbers, what makes a good alternative to thin cork sheets for treating sound issues inside rooms?

One excellent option is polyester fiber acoustic panels, which provide similar excellent absorption to fiberglass, while being safer and easier to work with.

The light polyester material simplifies installation using basic adhesive.

Compared to standard fiberglass, polyester won’t irritate the skin or respiratory system during handling and placement.

Polyester panels come in various thickness options, but 25mm to 50mm panels provide an ideal balance of cost-effectiveness and performance. The lighter weight eases mounting on walls and ceilings.

For the best broadband acoustic treatment, including taming low frequency bass buildup, fabric-wrapped polyester panels are recommended.

The outer fabric layer increases density slightly, which improves low end absorption compared to polyester alone.

Combined with the safety and installation benefits, fabric-wrapped polyester panels prove a great alternative to plain cork sheets when treating room echo and reverb issues.

Installed around key reflection points in a room, polyester acoustic panels will outperform thin cork for damping problematic reflections.

The improved depth and density enhances absorption across the full audible spectrum for superior echo and reverb control. For acoustic treatment, thicker polyester-based absorbers beat cork hands down.

How Does Our Advice Contrast With Other Sources?

Despite the physics showing the benefits of mass and thickness for proper sound blocking and absorption, many sources suggest otherwise.

Numerous general soundproofing guides, YouTube tutorials, and forum posts simply parrot the claim that 3mm cork sheets alone suffice for both soundproofing and acoustic treatment.

However these sources display a clear lack of understanding of the scientific principles involved in effectively insulating against sound transmission and absorbing problematic reflections within a space.

Without properly accounting for mass blocking sound waves and the need for thicker absorbers, the oft-repeated 3mm cork recommendation underdelivers on real acoustic control.

Here our aim is to provide expertise grounded in the science of acoustics to give you accurate, nuanced guidance on selecting the right materials and proper thickness needed for your specific project goals.

We do the diligent research required to filter fact from fiction when it comes to claims about soundproofing and acoustic products.

For insulating between living spaces, heavy mass and thickness is vital, making thin cork a poor choice despite claims otherwise.

For acoustic treatment within a room, sufficient absorber depth for low and high frequencies is crucial, again making 3mm cork fall short.

Don’t rely solely on random anonymous internet opinions and generic product descriptions. Leverage our expertise.

Conclusion

In closing, when it comes to soundproofing and acoustic treatment, cork thickness really does matter.

The oft-repeated claim that 3mm cork sheets suffice demonstrates a lack of understanding of the scientific acoustic principles involved.

For proper sound insulation between spaces, both mass and absorption are vital, requiring thick, dense materials like mass loaded vinyl and thick mineral wool.

3mm cork lacks the blocking mass needed for effective soundproofing.

Within a room, 25mm+ thickness is crucial for acoustic panels to absorb echos and reverb, allowing sound waves to penetrate rather than bounce around. Thin cork panels can’t provide enough depth.

Rather than blindly accepting dubious 3mm cork claims, leverage our expertise rooted in the science of acoustics.

We cut through the myths to provide accurate guidance on selecting high-performing soundproofing and acoustic treatment products for your specific needs.

Follow our advice for materials and thickness, and your project will meet noise control expectations.