You’ve just unboxed your brand-new acoustic foam panels, eager to improve the sound quality in your recording studio or home theater. But wait, why do they look so compressed, and can you toss them in the dryer to speed up their expansion?

Understanding the do’s and don’ts of acoustic foam—from its expansion to its maintenance—is crucial. Not only will this knowledge save you time and money, but it can also protect you from potential health risks and appliance damages.

Ready to become an acoustic foam expert? Let’s dive into everything you need to know.

What Materials Are Commonly Used In Acoustic Foam?

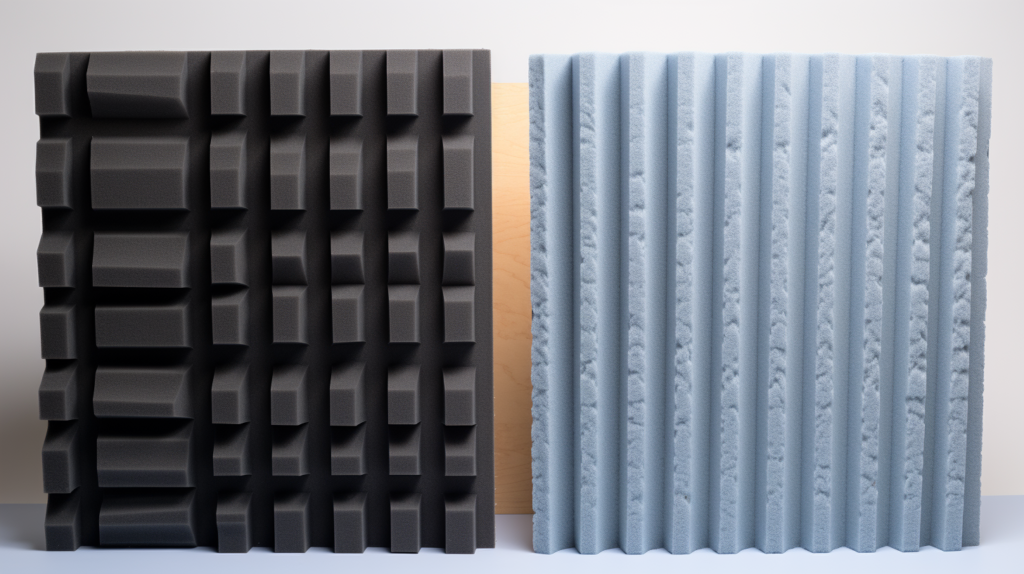

The acoustic foam market is flooded with various products, but one material stands out as the most commonly used—polyurethane. This versatile polymer is the backbone of most acoustic foam panels you’ll find on the market today.

But what makes polyurethane the material of choice for manufacturers and consumers alike?

Firstly, polyurethane is a polymer that exhibits an intricate balance of flexibility and rigidity. This balance is crucial for sound absorption, as the material needs to be firm enough to withstand the pressure of sound waves while being flexible enough to dampen them effectively.

It’s a fine line to tread, and polyurethane does it exceptionally well.

Secondly, the molecular structure of polyurethane is worth noting. Comprising long chains of organic units joined by urethane links, polyurethane’s structure allows it to be both lightweight and porous.

These characteristics are not just accidental byproducts but engineered features that make polyurethane highly effective at trapping sound waves, reducing echoes, and enhancing the overall acoustic quality of a space.

Why Is My Acoustic Foam Shipped In A Compressed Form?

One of the first things you’ll notice upon receiving your acoustic foam is that it arrives in a surprisingly small package. This is no mistake but a calculated decision by manufacturers to ship the foam in a compressed state.

This practice serves multiple purposes, each carefully considered to optimize the logistics and economics of delivering this product to your doorstep.

The primary reason behind shipping compressed foam is cost-efficiency. Acoustic foam panels, when fully expanded, take up a considerable amount of space. This volume would significantly increase the shipping costs, a price that would inevitably be passed on to you, the consumer.

By compressing the foam, manufacturers can fit more units into each shipment, thereby reducing the cost per unit and ultimately offering you a more affordable product.

Another aspect to consider is the environmental impact. Shipping larger, bulkier packages would require more space on trucks, planes, or ships, leading to increased carbon emissions.

In a world increasingly conscious of its environmental footprint, the compressed shipping method offers a more sustainable alternative.

Additionally, compressed packaging simplifies the handling process at every stage of the supply chain. From the warehouse workers who pack the foam to the delivery personnel who bring it to your door, smaller packages are easier to manage.

This ease of handling reduces the risk of damage during transit, ensuring that your acoustic foam arrives in the best possible condition.

Can You Expand Acoustic Foam In The Dryer?

Now, let’s address the burning question—quite literally—of whether you can put your compressed acoustic foam in the dryer to expand it. You’ve opened your compressed package, and you’re eager to get your acoustic setup ready. The idea of speeding up the expansion process with your household dryer seems tempting, but several factors should give you pause.

The Theory Behind Using The Dryer

On the surface, using a dryer to expand acoustic foam might appear to be a straightforward solution. After all, heat is a well-known catalyst for expansion in many materials.

The heat generated by the dryer, coupled with the tumbling action, might seem like the perfect combination to quickly and efficiently restore your foam to its original size.

However, several scientific and practical considerations challenge this theory. While heat is indeed a catalyst for expansion, its effects are not universal across all materials.

In some cases, heat can cause materials to degrade or even melt. Therefore, before you toss your compressed foam into the dryer, it’s crucial to understand how polyurethane interacts with heat.

What Does Science Say?

From a scientific standpoint, heat is energy, and when applied to a substance, it can cause the molecules to move faster and the material to expand.

However, this isn’t a one-size-fits-all phenomenon. Different materials have unique melting points, flash points, and chemical compositions that dictate how they respond to heat.

In the case of polyurethane foam, the material is complex and can behave unpredictably when subjected to heat. While low levels of heat can indeed cause the foam to expand, higher temperatures could compromise its integrity.

The foam could degrade, melt, or—worst of all—release toxic fumes. This brings us to an essential aspect that must be considered: safety.

What Are The Risks Of Putting Acoustic Foam In The Dryer?

Using a dryer to expand your acoustic foam might seem like a shortcut, but it’s essential to understand that this method comes with various risks.

These aren’t just minor inconveniences; they can lead to serious consequences that could affect your health and damage your appliances.

Could The Foam Be Toxic?

The potential toxicity of heating polyurethane foam is a grave concern. When subjected to heat, especially at high temperatures, polyurethane can emit hazardous fumes.

These fumes can contain isocyanates, chemicals that are known to be harmful to humans and animals when inhaled.

But the issue of toxicity doesn’t stop at the point of exposure. Once these toxic fumes are released, they can linger in your home environment, posing a longer-term health risk.

Continued exposure to such fumes could lead to respiratory issues, eye irritation, and even more severe health conditions. It’s not just a concern for you but for anyone who shares your living space, including pets.

Therefore, the risk of toxic emissions alone should make you think twice about using a dryer to expand your acoustic foam.

Can It Damage The Dryer?

While the human health risks are paramount, another substantial concern is the potential damage to your dryer. Dryers are designed to handle fabrics and are not equipped to deal with materials that could melt or disintegrate.

If polyurethane foam were to melt inside the dryer, the cleanup would be a monumental task.

Melted foam could adhere to the dryer’s drum and even penetrate the machine’s internal mechanisms. This could lead to functional issues and might necessitate repairs or, in the worst-case scenario, a complete replacement of your appliance.

Considering that a new dryer is a significant investment, risking it to expand a piece of foam is a gamble that doesn’t seem worth taking.

Are There Safer Methods To Expand Compressed Acoustic Foam?

So, if using a dryer is fraught with risks, what are the safer alternatives? Fortunately, there are methods to expand your compressed acoustic foam that don’t involve risking your health or damaging your appliances.

The Natural Method

The safest route is often the most straightforward one. Simply allowing your acoustic foam to expand naturally is a foolproof method. Place the foam in a well-ventilated area and give it time to regain its original size and shape.

Depending on various factors, such as room temperature and humidity levels, this could take anywhere from a few hours to a couple of days.

This method requires patience, but it offers peace of mind. You won’t have to worry about toxic fumes or appliance damage.

Plus, allowing the foam to expand naturally ensures that it retains its structural integrity, which is vital for its effectiveness in sound absorption.

The Manual Method

If waiting for natural expansion isn’t appealing, there’s another safe but slightly quicker method: manual expansion. This involves carefully stretching and pulling the foam to aid the expansion process.

While this method requires more physical effort, it provides a quicker path to using your foam without the risks associated with using a dryer.

By using your hands to expand the foam, you have more control over the process. You can feel the foam’s resistance and elasticity, ensuring you don’t damage its structure.

This hands-on method also allows you to inspect the foam for any defects or issues, giving you a better understanding of the product you’ve purchased.

Is It Safe To Wash Acoustic Foam In The Washing Machine?

As you consider the maintenance of your acoustic foam, another question that often comes up is whether it’s safe to wash these foam panels in a washing machine.

The notion of easily cleaning your acoustic foam in a machine is appealing, but several complications arise when you delve into the specifics.

Washing machines are designed to handle fabrics and are calibrated for specific washing conditions like temperature and agitation level. Acoustic foam, with its unique material properties, may not be suitable for such an environment.

While it might seem like a convenient shortcut, the chances of damaging your foam or even your washing machine should make you reconsider this option.

Why Shouldn’t You Wash Acoustic Foam In The Washing Machine?

The detergents used in washing machines are formulated to remove stains from fabrics. They are not designed for materials like polyurethane foam, which has a different chemical composition.

Using such detergents on your acoustic foam could lead to adverse chemical reactions that might degrade its structure or even produce harmful substances.

The mechanical action of the washing machine could also be too harsh for the delicate structure of the foam. The agitation and spinning might distort its shape, reduce its effectiveness in absorbing sound, or even tear it apart.

Any of these outcomes would essentially render your acoustic foam useless for its intended purpose, leading to unnecessary costs for replacement.

How Can You Clean Acoustic Foam Safely?

Given the risks involved in using a washing machine, it’s essential to know how to clean acoustic foam safely. The good news is that maintaining your foam panels doesn’t require specialized equipment or harsh chemicals.

A Mild Detergent And Water Are Usually Sufficient

The most straightforward way to clean your acoustic foam is with a mild detergent and water. Fill a basin or sink with lukewarm water and add a small amount of mild detergent.

Immerse the foam panels and gently agitate them using your hands. This method ensures that you remove dirt and stains without exposing the foam to harsh chemicals or mechanical stress.

Proper Drying Is Crucial

Once you’ve cleaned your acoustic foam, drying it properly is just as important. Incorrect drying can lead to issues like mold and mildew, which could degrade the foam and pose health risks.

The best way to dry your foam is to place it in a well-ventilated area away from direct sunlight. The air circulation will facilitate drying, while avoiding sunlight will prevent the foam from degrading due to UV exposure.

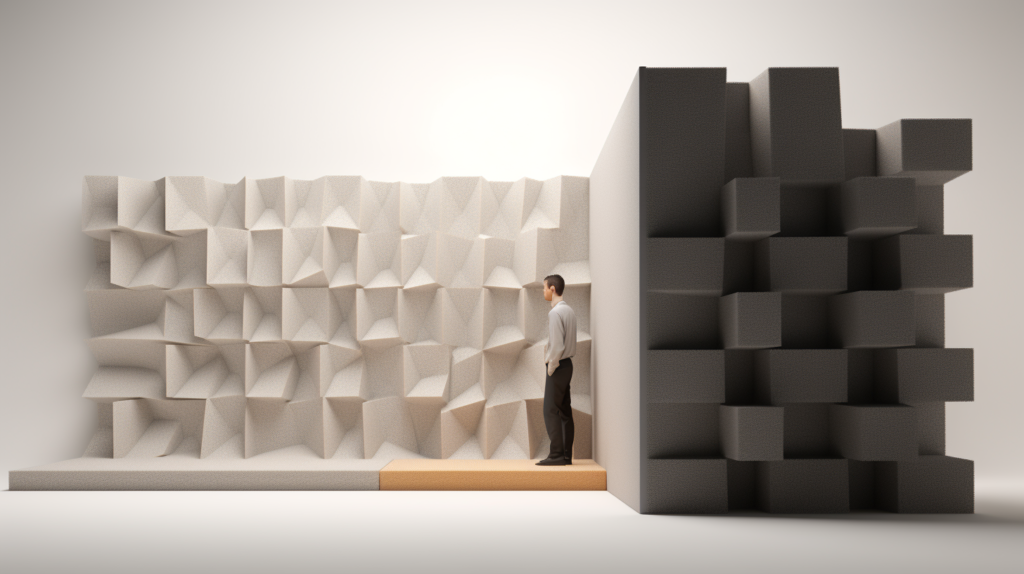

Are Polyester Acoustic Panels A Better Option?

If you find the care and maintenance of polyurethane acoustic foam too daunting, you might consider polyester acoustic panels as an alternative. These panels offer many of the same benefits as polyurethane foam but come with added advantages.

Durability And Ease Of Maintenance

Polyester acoustic panels are known for their durability. They are less susceptible to wear and tear compared to polyurethane foam, making them a long-lasting option.

This durability extends to maintenance; polyester panels can often be cleaned with a simple wipe-down using a damp cloth, making them far less labor-intensive to maintain.

Eco-Friendly And Aesthetically Versatile

Many polyester acoustic panels are made from recycled materials, making them an eco-friendly choice. They are also available in a variety of colors and patterns, giving you more options for interior design.

Thus, polyester acoustic panels offer both functional and aesthetic benefits that could make them a more suitable choice for your needs.

Conclusion

If you’ve made it this far, you’ve armed yourself with a wealth of knowledge on the intricacies of acoustic foam and its care. From the risks associated with using a dryer for expansion to the safer alternatives and maintenance tips, we’ve covered a broad spectrum of relevant topics.

So, what should you take away from all this information?

Firstly, it’s crucial to recognize that while the idea of using household appliances like dryers and washing machines to deal with your acoustic foam may seem convenient, it’s fraught with risks.

These risks can have a significant impact, from health hazards due to toxic fume emission to potential damage to your appliances. Therefore, it’s advisable to steer clear of these methods.

Secondly, patience is your best friend when it comes to expanding and maintaining your acoustic foam. Natural expansion methods, although time-consuming, are the safest and most reliable.

Similarly, hand-washing your foam panels with a mild detergent is the recommended cleaning method. It may require more effort than tossing them into a washing machine, but it ensures the longevity and effectiveness of your acoustic foam.

Lastly, if you find the requirements for caring for polyurethane foam too demanding, consider polyester acoustic panels as an alternative. These panels offer similar acoustic benefits but are more durable and easier to maintain.

They can also be a more eco-friendly option if made from recycled materials.

Frequently Asked Questions (FAQ): What Else Do You Need To Know?

In addition to the primary concerns addressed, there are a few more questions that often arise when it comes to dealing with acoustic foam. Let’s tackle some of these to give you an even more rounded understanding of the topic.

Can I Speed Up The Natural Expansion Process?

If waiting for your acoustic foam to naturally expand feels like watching paint dry, you might wonder if there’s a way to expedite the process.

While there’s no magic trick to make it happen instantly, ensuring that the foam is in a well-ventilated room at room temperature can aid quicker expansion. Flipping and rotating the panels occasionally can also help.

Are There Specialized Cleaners For Acoustic Foam?

Yes, specialized cleaners for acoustic foam do exist. However, these are usually not necessary for regular maintenance.

A mild detergent and water are generally sufficient for most cleaning tasks. Specialized cleaners may be beneficial for tackling more stubborn stains or for commercial settings where the foam is exposed to higher levels of dirt and grime.

Is It Possible To Repair Damaged Acoustic Foam?

If you’ve accidentally damaged your acoustic foam, you might be hoping for a way to repair it. However, it’s crucial to note that acoustic foam is generally not repairable.