Struggling to find the best adhesive for properly mounting acoustic foam panels?

Selecting the right mounting adhesive is crucial for securing panels and enabling effective sound absorption over the long term.

Let’s explore recommendations based on installation needs.

What Adhesive is Best for Acoustic Foam?

For most standard acoustic foam panels, heavy-duty multi-purpose construction adhesive provides optimal bonding power and permanence across many surfaces.

But removable putty or double-sided foam tape may suit temporary mounting needs better.

We’ll explore adhesive options for acoustic foam further below.

What is Acoustic Foam?

Acoustic foam refers to sound-absorbing foam panels that are used to reduce echo, reverberation, and other excessive reflections of sound waves in a room or enclosed space.

They work by using open cell structures to absorb sound energy and convert it into heat energy instead of reflecting it back into the room.

Acoustic foam is commonly used in recording studios, listening rooms, home theaters, offices, basements, and other specialized spaces where controlling reverberation and reflections is important.

The foam itself is usually made from melamine, polyurethane, acrylic, or other porous materials.

The open cell structure with interconnecting holes allows sound waves to penetrate deep into the foam and get trapped, rather than bounce back into the room.

This leads to a reduction in excessive reverb and echo that can muddy up a room’s acoustics.

Choosing the right type of acoustic foam and mounting it correctly on walls and ceilings is key for optimal sound absorption.

Acoustic Foam Adhesive Considerations

Installing acoustic foam properly depends greatly on selecting the best adhesive and application method.

There are a few key factors to consider when deciding on which adhesive to use:

Permanence

Do you need a permanent adhesive for long-term installation or a temporary mounting option? Permanent mounting like construction adhesive creates a much stronger, resilient bond.

But temporary mounting putty may be a better solution if you need to take panels down periodically or want more flexibility.

Surface Type

Consider if you are installing foam on a smooth, flat surface like drywall or concrete.

Or is the surface uneven and textured like faux or real brick? The texture and porosity of the surface area will determine which adhesives work best.

Foam Type

Standard acoustic foam requires adhesive, but newer self-adhesive acoustic foam products have a peel-and-stick backing for easier installation.

The adhesive requirements differ considerably between standard foam versus self-adhesive foam panels.

Environment

What temperature, humidity, cleanliness, and other environmental conditions are present? Extreme high or low temperatures may impact curing times.

Dust and oils can also inhibit adhesive bonds.

Consider the room’s environment when selecting and applying adhesive.

Recommended Adhesives

For Permanent Mounting

Construction Adhesives

Construction adhesive, also sometimes called panel adhesive, creates an incredibly strong, permanent bond between surfaces.

It is designed for strength and resilience, making it a top choice for permanently affixing acoustic foam to walls and ceilings.

Construction adhesive maintains its flexibility over time while keeping good surface tack.

Due to its thick consistency, Construction adhesive also works very well on uneven, porous surfaces like concrete, brick, and textured walls.

It can span gaps between the foam and substrate nicely.

When properly applied, construction adhesive dries solid and offers impressive holding power in hot, cold, wet, or dry conditions.

It is an ideal all-purpose permanent adhesive for acoustic foam.

Acoustical Sealant

In addition to construction adhesive, acoustical sealant is another smart option for permanently mounting acoustic foam panels.

Acoustical sealants provide a superior noise-blocking barrier thanks to their non-hardening flexibility and vibration damping abilities.

Acoustical sealant helps seal in sound absorption while keeping out exterior noise by creating an airtight yet flexible barrier between the foam and mounting surface.

This makes it popular for music studios and other critical listening environments.

It also works for sealing foam panels around electrical outlets, air vents, and corners.

Unlike harder drying glues, acoustical sealant remains somewhat flexible after curing while still providing impressive bonding strength.

This allows it to constantly mitigate sound leaks and gaps as the building settles.

For permanent mounting that actively assists in sound control, acoustical sealant is an optimal choice.

Just be sure to choose a sealant rated for permanent, long-term use rather than a temporary craft-type sealant.

For Temporary Mounting

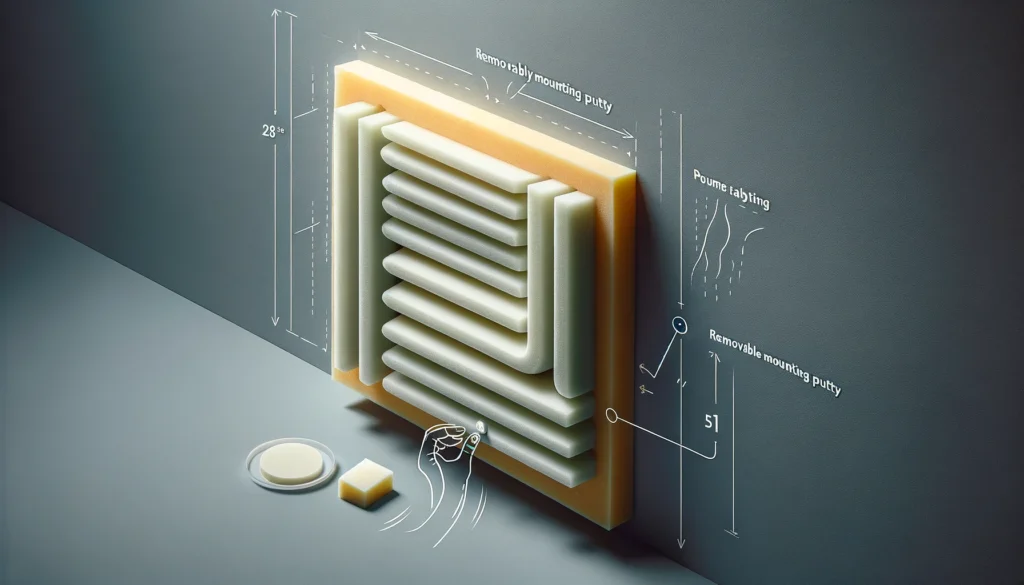

Removable Mounting Putty

Using removable mounting putty allows temporary adhesion of acoustic foam panels to smooth surfaces.

Removable putty only creates a physical bond rather than a chemical cured bond.

So acoustic foam adhered with putty can be easily removed whenever necessary without leaving behind any residue or damaging the surface underneath.

Most removable putties also let you reposition panels multiple times during the layout process before firmly pressing them in place.

Just be sure to choose putty designed specifically for foam rather than plain poster putty.

Foam putty is softer and more malleable to prevent indentations in the foam.

It also contains no oils that could stain or discolor acoustic treatments over time.

Easy, damage-free removal makes foam mounting putty ideal for rentals, shared creative spaces, trade shows, and other temporary applications of acoustic foam.

Double-Sided Acoustic Foam Tape

Using professional-grade, high-performance double-sided foam tape presents another temporary yet resilient adhesive option.

Specialized acoustic foam tapes utilize a thin, open cell foam carrier rather than paper or film.

The acoustic foam itself allows enhanced sound absorption while the strong acrylic adhesive temporarily bonds panels to textured and uneven surfaces.

Double-sided acoustic foam tapes can grip reliably on rough substrates that mounting putty may struggle with.

Peel and stick application makes installation, removal, and repositioning fast and simple.

Foam tape performs well over a wide temperature range too.

For temporarily adhering foam panels to textured or uneven walls, double-sided acoustic foam tape offers quick yet robust adhesion.

Proper Application Techniques

To achieve optimal adhesive strength plus audio performance from acoustic foam panels, follow these best practices:

Surface Preparation

Properly prep the entire mounting area before applying adhesive to acoustic foam or surfaces.

Clean walls thoroughly with isopropyl alcohol to remove any dust, oils, or debris left behind.

Lightly sand shiny paints and finishes to improve adhesion.

Use painter’s tape to map out panel layouts beforehand.

Prep is crucial for maximum adhesive bonding strength.

Adhesive Application Tips

Apply adhesive either directly onto acoustic foam backing or spread evenly across marked mounting areas.

Follow adhesive instructions carefully regarding spread rate and application method.

With tapes or sealants, ensure 100% contact coverage.

For larger panels, apply adhesive near edges plus in a grid pattern over the entire surface area.

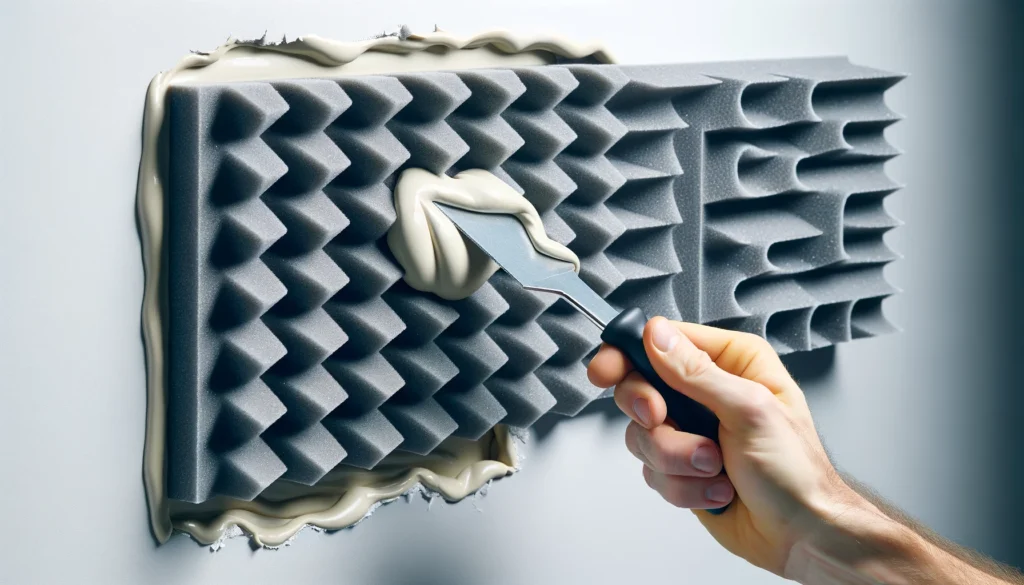

Use a solvent-safe adhesive spreader to smooth and level adhesive applied onto walls for the most reliable bonds.

Press Foam Panels in Place

Once adhesive is prepped on both the acoustic foam panels and mounted surfaces, carefully press panels into place per your pre-planned layout.

Apply even pressure across all areas of foam panels to promote full contact bonding with adhesive underneath.

Use a roller over the attached foam panels to help maximize adhesion strength.

Allow Proper Curing Time

Leave foam panels completely undisturbed while adhesive fully cures.

Avoid prematurely testing bonds or exposing to humidity, direct sunlight, or extreme hot or cold during the curing period.

For construction adhesives and sealants, clamping panels for the first 8 to 24 hours helps strengthen connections as it solidifies.

Allow adhesive to fully cure before evaluating finished look and acoustic performance.

Avoiding Common Mistakes

Prevent these common acoustic foam mounting mistakes:

Using Improper Adhesive for Surface Type

A textured, porous concrete wall requires very different adhesive than a smooth drywall ceiling.

Make sure to match the adhesive properties like flexibility, drying time, and composition to the mounting surface type for reliable bonding.

Applying Too Little or Too Much Adhesive

Every adhesive has an optimal spread rate and thickness for proper curing and bonding.

Applying too little adhesive can lead to weak spots, gaps, and falling panels.

But adhesive that is too thick and heavy can ooze, preventing good foam contact and drying fully.

Carefully follow manufacturer advised usage rates.

Not Following Recommended Curing Times

All adhesives need ample time to set, cure, and bond correctly to grip surfaces.

Prematurely disturbing panels or loading weight onto them can disturb the curing process and negatively impact hold strength.

Exercise patience during adhesive curing times for worry-free mounting.

Conclusion

Choosing the right adhesive plays a crucial role in both the installation process and long-term performance of acoustic foam panels.

Consider permanence needs, surface type, foam backing, project environment, application methods, and curing times when selecting which construction adhesive, sealant, removable putty, or double-sided foam tape to use.

Following manufacturer guidelines and installation best practices will result in securely mounted panels that absorb sound beautifully.

With quality adhesive and attentive application, acoustic foam can drastically enhance room acoustics and audio clarity.