Are you tired of the constant noise distractions in your workspace or home theater, affecting your focus and enjoyment?

While various solutions promise to tackle noise issues, acoustic panels have proven to be one of the most effective remedies.

However, the material they’re made from can significantly impact their performance.

In this guide, we’ll explore why polyester fiber is the superior choice for acoustic panels.

So, let’s dive into the nitty-gritty details.

What Types of Materials Are Commonly Used in Acoustic Panels?

When it comes to materials used in acoustic panels, foam is one of the most commonly employed.

However, it’s crucial to clarify that we’re discussing mineral wool and fiberglass types of foam, not polyurethane foam.

These types of foam are especially effective in absorbing high-frequency sounds, making them ideal for settings like recording studios or places where speech clarity is essential.

Another option is fabric-wrapped acoustic panels. These panels are essentially a core material like fiberglass wrapped in fabric.

They are often used for aesthetic reasons, as they come in various colors and designs.

Fabric-wrapped panels are effective in absorbing mid-range frequencies, making them suitable for spaces like conference rooms or auditoriums.

Wood also finds its way into the construction of acoustic panels but is less common compared to foam and fabric.

Wooden acoustic panels are generally used for their aesthetic appeal rather than their sound-absorbing capabilities.

They are often employed in settings where the decor is as crucial as sound management, like luxury hotels or high-end restaurants.

Why Is the Material Important in Acoustic Panels?

The type of material used in an acoustic panel is not just a matter of aesthetics; it also has functional implications.

Different materials offer different levels of sound absorption, which is measured in terms of a Noise Reduction Coefficient (NRC) rating.

Higher NRC ratings mean better sound absorption, and the material of the panel plays a vital role in determining this rating.

Selecting the right material also depends on the specific acoustic needs of a space.

For example, foam panels made from mineral wool or fiberglass are effective for high-frequency sounds and are well-suited for music studios.

On the other hand, fabric-wrapped panels are better for absorbing mid-range frequencies, making them ideal for conference rooms where speech clarity is important.

How Is Polyester Fiber Changing the Acoustic Panel Industry?

Polyester fiber is rapidly emerging as a game-changer in the acoustic panel industry.

It’s a synthetic material that combines the best of both worlds: lightness and density.

Its lightweight nature makes it incredibly easy to install, even in challenging spaces where traditional materials might be cumbersome.

Moreover, despite its lightness, polyester fiber boasts a dense structure. This density is crucial for effective sound absorption across various frequency ranges.

It means that polyester fiber panels are not just suitable for high-frequency sounds like foam panels or mid-range frequencies like fabric panels.

They are all-rounders, capable of effective sound management across a broad spectrum.

What Are the Advantages of Using Polyester Fiber in Acoustic Panels?

The advantages of using polyester fiber in acoustic panels are numerous. One of the most prominent benefits is its lightweight nature.

This quality makes it easier to handle and install, reducing labor costs and installation time.

In addition, the density of polyester fiber contributes to its excellent sound absorption properties.

The material can absorb sound waves effectively across different frequency ranges, making it a versatile choice for various applications.

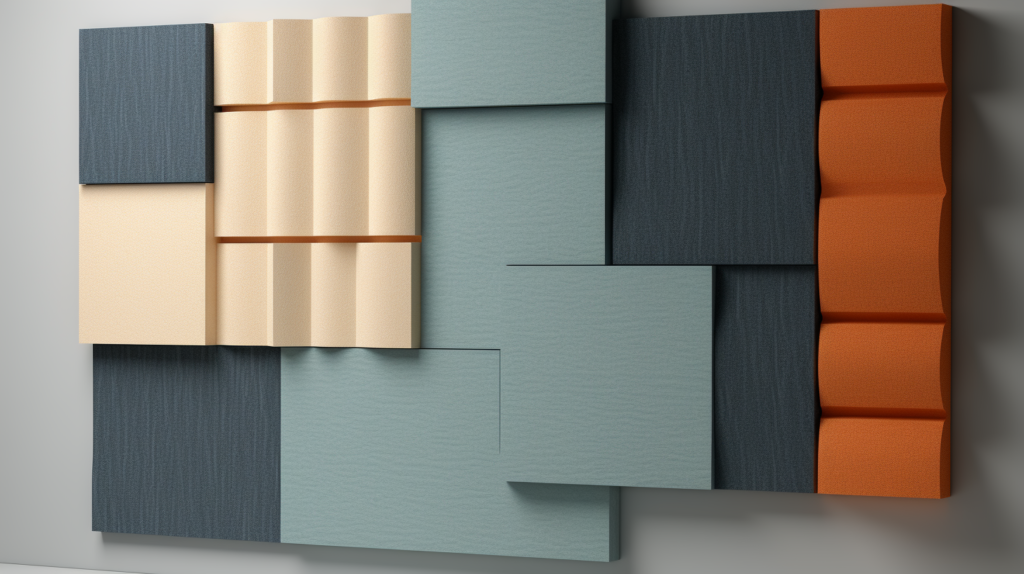

This versatility also extends to design options. Polyester fiber panels come in a variety of designs and colors, offering greater aesthetic flexibility than other materials.

How Does Polyester Fiber Compare to Other Acoustic Panel Materials?

When it comes to comparing polyester fiber with other materials like mineral wool or fiberglass foam, the former often emerges as the superior option.

One of the primary reasons for this is the range of frequencies that polyester fiber can effectively absorb.

Unlike foam panels, which are more suited for high-frequency sounds, polyester fiber can handle a broad spectrum, making it more versatile.

It’s not just about sound absorption; it’s also about aesthetics. Polyester fiber panels offer greater design flexibility compared to fabric-wrapped panels.

They are available in a range of colors and designs, which means they can be customized to fit the decor of a room perfectly.

This adds an extra layer of appeal to these panels, making them not just functional but also visually pleasing.

Is Polyester Fiber a Sustainable Choice for Acoustic Panels?

Sustainability is becoming an increasingly important factor in material selection, and polyester fiber excels in this area as well.

Many polyester fiber acoustic panels are made from recycled materials, such as PET bottles. This makes them an eco-friendly choice for those looking to minimize their environmental impact.

Furthermore, polyester fiber itself is recyclable. At the end of its life cycle, it can be broken down and reused, further contributing to its eco-friendly credentials.

This recyclability is not just good for the planet; it’s also a selling point for consumers and businesses looking to make sustainable choices.

Where Are Polyester Fiber Acoustic Panels Most Commonly Used?

The versatility of polyester fiber acoustic panels makes them suitable for a wide range of settings.

Commercial spaces like offices, restaurants, and retail stores often employ these panels to manage sound effectively.

In these environments, sound clarity and noise reduction are vital for customer satisfaction and employee productivity.

Residential spaces are also increasingly adopting polyester fiber acoustic panels. Home theaters, living rooms, and even bedrooms can benefit from the sound-absorbing qualities of these panels.

They not only enhance the auditory experience but also add to the aesthetic appeal of a room, thanks to their design flexibility.

How Can You Choose and Install Polyester Acoustic Panels?

Selecting the right polyester acoustic panels involves considering several factors, the first of which is the size of the space.

Panels come in various sizes and thicknesses, each suitable for different sound absorption needs. It’s crucial to measure your space and assess its acoustic requirements before making a selection.

Installation of polyester acoustic panels is generally a straightforward process, thanks in part to their lightweight nature.

Many products come with installation guides and even kits to assist you. However, for more complex installations or larger spaces, professional help may be advisable to ensure optimal sound absorption.

Conclusion

Polyester fiber excels in both sound absorption and design versatility, outperforming traditional materials like mineral wool and fabric-wrapped panels.

Its lightweight nature makes installation easy, while its density ensures effective sound management. Additionally, its eco-friendly attributes make it a sustainable choice in today’s environmentally conscious world.

Simply put, for a versatile, efficient, and sustainable acoustic solution, polyester fiber is the best choice.