Do all MIDI controller mod wheels function the same?

The answer may surprise you.

While mod wheels are standard features on most MIDI keyboards and controllers, there are actually significant differences between models regarding physical design, resolution, spring tension, assignability, and more.

Let’s take a closer dive to explore the key variance between MIDI mod wheel implementations and see how these factors impact playability and software integration.

Do MIDI Controller Mod Wheels Vary?

Yes, while mod wheels are standard on MIDI keyboards and controllers, there are major differences between models regarding physical factors like size and shape, resolution, spring tension, and assignability that affect playability and software integration.

We’ll explore these key variances in depth below.

What is a Mod Wheel?

A mod wheel refers to a special controller which is included on most MIDI keyboards and controllers and which allows for real-time modulation and effects changes.

The mod wheel typically takes the form of a wheel which can be physically moved up or down in order to send continuous controller (CC) data to connected devices and plugin software.

By default, mod wheels send data on CC number 1.

The position of the mod wheel corresponds to a data value between 0-127, where 0 represents no modulation and 127 represents full or maximum modulation.

As one of the most used and convenient hands-on controllers, mod wheels are extremely popular for adding expression and dynamics to performances.

However, it should be noted that not all hardware devices and software plugins fully recognize the wide range of 0-127 for the mod wheel data.

Some equipment may utilize a narrower range or have customized interpretations of vthe data.

So functionality can differ across devices.

Range of Values

The MIDI specification allows for a range of 128 possible values (0-127) to be transmitted by the mod wheel controller.

A position of 0 means no modulation effect or the minimum possible amount, while 127 represents fully applying whatever modulation or parameter change that the mod wheel is assigned to.

For example, if the mod wheel is assigned to control vibrato amount within a software synthesizer, moving the wheel to the top position would apply maximum vibrato effect.

Setting it at the halfway point may apply a medium amount, and all the way at the bottom would turn it off for no vibrato effect.

The availablesounds and potential for expression are greatly expanded by having 128 increments.

Differences Between Controllers

There can be major physical and functional differences between mod wheel implementations on MIDI keyboards, controllers, and other hardware devices.

Physical Size and Shape

Mod wheels are produced with a wide variety of physical designs.

Standard wheels tend to be fairly small at just a few inches across, but larger wheels and long lever-style controllers can also be found.

The shape and size impacts the accuracy and ease at which the performer can manipulate them.

Larger wheels and levers allow for more precision in hitting exact desired values, while compact wheels may involve more estimation.

The tension and spring resistance also plays a role in control.

Overall, mod wheel design is an important factor in playability.

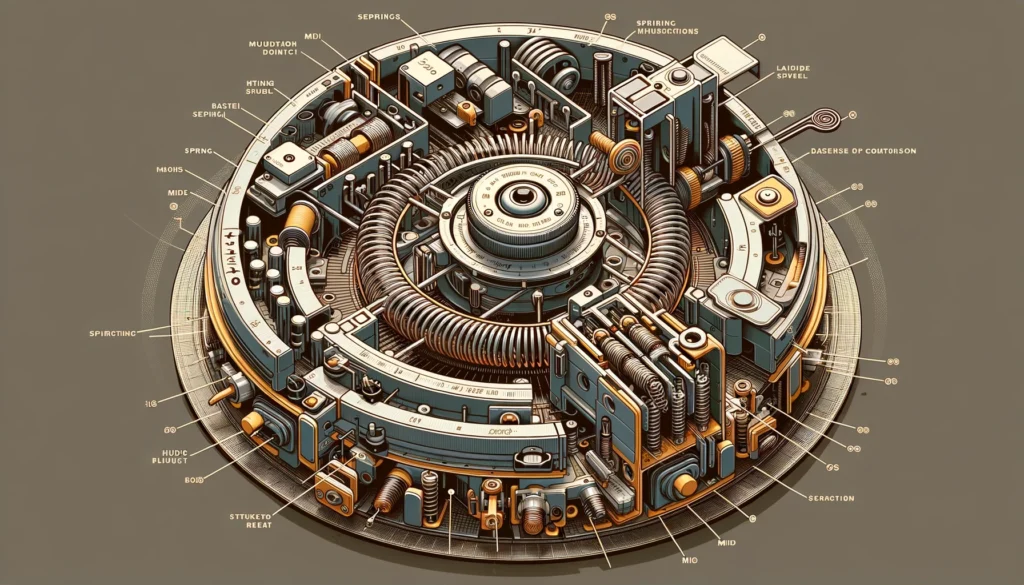

Spring Tension

Many mod wheels utilize internal spring mechanisms to provide both rotation and tactile feedback, as well as self-centering functionality.

After the wheel is rolled up or down, the springs quickly snap the wheel back into the center resting position.

However, some controllers have loose wheels without springs that do not self-center.

Having the consistent spring tension provides a reliable reference point, so the performer knows the mod wheel position even without looking directly at it.

Loose, non-spring wheels may tend to drift around, requiring more visual verification to determine their status.

High Resolution Values

Standard MIDI mod wheel messages utilize 7 bits to transmit wheel values on a range of 0-127.

However, some advanced MIDI keyboards and controllers are capable of sending higher resolution, 14 bits worth of data.

This allows for a whopping 16,384 possible values instead of just 128.

Having thousands more increments enables extremely minute changes and smooth sweeps in whatever parameter is being controlled.

Certain new equipment and software can recognize and make use of the enhanced high-resolution data.

However, compatibility isn’t universal, so the high resolution may not function properly with older MIDI gear or certain programs.

Assignability

Most MIDI keyboards have the mod wheel permanently assigned to control CC number 1 only.

Yet on some hardware controllers, it is possible to reassign the wheel to transmit a different CC number instead.

Often this is done through a configuration menu in the device’s system software.

Custom assigning the controller wheel or lever provides increased flexibility.

For example, it could be set to control volume (CC 7), pan position (CC 10), or other parameters besides the standard modulation.

Advanced users may wish to standard wheel behaviors this way.

However, compatibility and proper parameter assignments need verification within any connected software or sound devices.

So in summary, some key differences between mod wheels on MIDI controllers relate to their physical design/size which impacts playability, their self-centering spring mechanisms or lack thereof, enhanced high resolution transmission capabilities in some models, and the ability for custom remapping some wheels to non-standard CC assignments.

These factors significantly alter the hands-on performance, precision, and software integration capabilities.

Conclusion

In exploring MIDI controller mod wheels, there is certainly more than initially meets the eye.

Underneath the relatively uniform appearance of spinning wheels, there are major differences in terms of hardware implementation, data transmission, and functionality.

Getting to know the specifics of a particular mod wheel, especially advanced features included by some manufacturers, allows musicians to get the most expressiveness and capabilities from their devices.

With MIDI technology constantly advancing, no doubt additional innovations in mod wheel design lie ahead as well.