Do you cringe every time your neighbor’s TV blasts through your paper thin walls? Or does your toddler’s tantrum pierce the peaceful silence you crave?

Thin walls that let sound freely travel are the bane of apartment and condo dwellers everywhere.

Transforming those noise-leaking walls into an effective sound barrier is possible with the right materials and installation method. Proper planning and diligent sealing are key to dramatically reducing bothersome sound transmission between rooms.

Let’s dive in to learn the steps for evaluating your needs, choosing a soundproofing technique, prepping the wall, installing insulation or dampening panels, meticulously sealing gaps, and adding finishes.

Step 1: Evaluate Noise Sources And Goals

The very first step before any physical soundproofing work begins is fully evaluating the types of noises involved and defining your soundproofing goals. Without understanding the core issues and your ideal end state, it is impossible to choose the right soundproofing tactics.

Take time to detect the main noise sources, analyze how the sound travels, and decide on your targets for noise reduction.

Start by scrutinizing exactly what noises are causing problems and when they primarily happen.

Pay close attention to whether the most bothersome noises are airborne sounds that travel easily through walls, such as voices, music, television – or more structure-borne noises like footsteps that vibrate through the physical wall.

Also take note of whether the noise issues arise mainly during the day versus at night. Understanding the dominant sound types and timings will inform the best options.

Next, examine how the troubling noises are transmitting. Walk through your space and pinpoint the precise path the sound takes.

Check common sound leakage points like electrical outlets, vents, under the door, or thin window panes.

Isolate gaps in the physical wall construction itself that allow sound to pass through. Narrow down if deficiencies in the wall surface materials themselves are contributing to noise transfer.

Tracing the sound’s pathway is crucial for sealing off all vulnerabilities later.

With the noise sources and pathways identified, define your ideal soundproofing goals. Determine the levels of reduction necessary to mitigate issues versus any maximum soundblocking overkill that provides diminishing additional benefit.

Set specific targets for lowering noise volumes and increased privacy that solve your core problems. You may aim for slightly muffling loud voices or more dramatically eliminating all noise transmission.

Match your ambitions to the proper level of time and investment.

Having performed this detailed diagnostic work to isolate noise types, transmission methods, and ideal soundproofing targets, you can make informed choices about appropriate materials and installation techniques. Do not skip this critical planning step!

Step 2: Prepare The Wall

After thoroughly evaluating the soundproofing project scope, next prepare the wall itself for installation work. Proper prep sets the stage for success by stabilizing and cleaning the wall surface, sealing up vulnerabilities, and enhancing access.

Rushing ahead without prep risks compromising the end results.

Start by clearing any pictures, shelves, outlets or other fixtures from the wall area. Remove nails, hooks or anything protruding.

Eliminate debris like flaking paint that could impede installation. Any accessories can be reinstalled later after completing the soundproofing.

With the wall surface clear, seal up any visible gaps, holes or penetrations. Acoustic sealant is a specialized caulking that blocks sound transmission.

Liberally apply it around wall edges, electrical and plumbing outlets, air vents and returns. Look for cracks or crevices throughout the wall and fill them with sealant as well.

The goal is creating a continuous surface that cannot leak noise.

If utilizing the decoupled wall technique, now is also the time to expose the inner wall studs. This provides attachment points to insulate between each stud bay when adding the new interior wall layer.

Carefully cut and pry off the drywall, removing any nails and screws. Alternatively, it may be possible to install new vertical studs directly on top of the existing wall, avoiding teardowns.

Inspect the now stripped wall and address any remaining deficiencies like sparse insulation or decaying materials. Installing the soundproofing layers is easiest on an intact, sealed surface anchored to solid studs or layers of horizontal furring strips.

The time devoted to thorough prep always pays off later.

Step 3: Add Sound Dampening Materials

With a prepped wall ready, it is time to install the materials that actually dampen noise and provide soundproofing benefits. This is where the process divides based on whether you are creating a decoupled wall or installing sound dampening panels.

Each has pros and cons.

Option 1: Decoupled Wall

A decoupled wall provides maximum sound blocking by both absorbing and isolating noise. To create one, cut sound insulating materials like mineral wool batts to snugly fit between each exposed wall stud bay or furring strip layer.

This insulation prevents noise transmission through the wall structure itself.

Mineral wool materials like Roxul or fiberglass batts rate very highly for noise absorption. The dense, porous surface traps sound waves rather than letting them pass through.

Cut pieces to exactly fill each stud bay to prevent gaps. Use gentle pressure to hold the insulation in place while installing the rest of the decoupled wall system.

In addition to absorbing airborne noises, dense insulation batts also dampen vibration and impact sounds by decoupling the interior and exterior wall.

Noise tries to travel laterally through the framing but encounters disconnected surfaces that contain the sound. A properly insulated decoupled wall addresses the full range of noise issues.

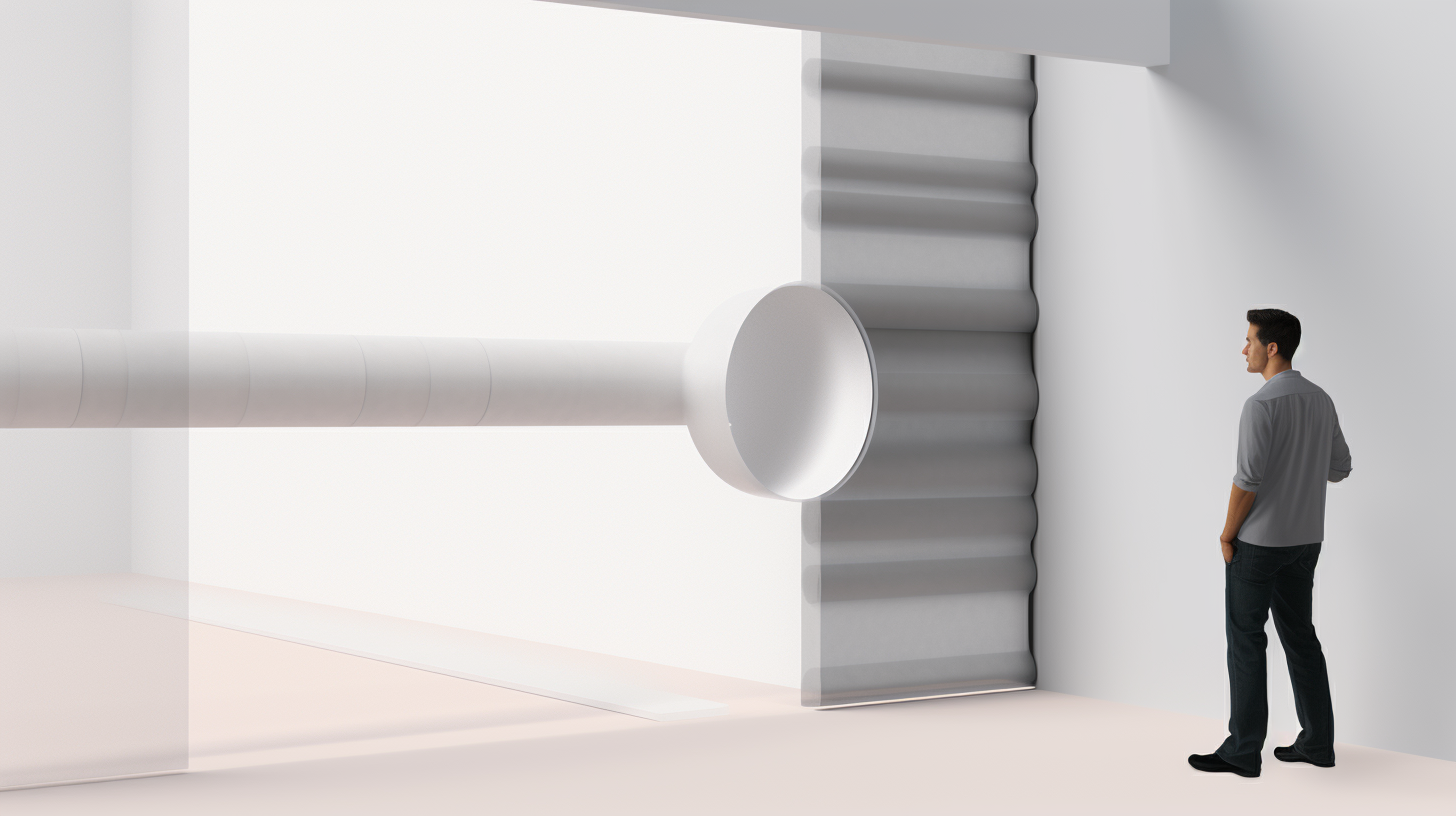

Option 2: Sound Dampening Panels

If aiming to primarily block airborne noise transfer rather than structural sounds, installing focused sound dampening panels is simpler than creating an entire decoupled wall.

These panels made from materials like mass loaded vinyl or thermoplastic sheets provide noise reduction by diffusion and absorption.

Measure the wall surface and cut sheet panels to size using a utility knife or sharp shears. Many quality prefabricated audio dampening panels are also available in standard dimensions to simplify this process.

Apply a specialized acoustic adhesive to the backside of the panels per manufacturer instructions.

Once adhesive is prepared, press panels directly against the wall surface, smoothing over the entire area. Focus on consistency and full coverage rather than aesthetics.

Leave no gaps between panels and use multiple layers for superior results.

Most brands only require a few hours for the adhesive to fully cure. Sound dampening panels require less installation work compared to the full decoupled wall method.

Step 4: Install New Wall Layer

For a full decoupled wall installation, additional layers are required after the sound dampening insulation. The next step is installing resilient channels over the insulation filled stud bays, then attaching new drywall on top to complete the enhanced wall buildup.

Resilient channels are long, thin brackets made from galvanized steel. Attach them horizontally across each wall stud using the pre-drilled flange holes and drywall screws.

Channels should be placed a maximum of every 24 inches. Staggering channels on opposite sides of each stud provides greater support for the drywall.

With channels installed, cut drywall panels to size and screw them into the channel flanges using drywall screws at least 1 1⁄4 inches long. This forms the new inner wall layer separated from the original exterior wall by the resilient channels and insulation.

Continue attaching drywall sheets until the entire area is covered. The channels allow the drywall to be completely decoupled and isolated for even greater sound dampening.

If using adhesive sound dampening panels, the panel material itself acts as the new surface layer. Ensure 100% coverage without gaps directly over the old wall.

No additional layers are needed. Press panels firmly during installation to maximize acoustic contact area.

Step 5: Seal All Seams and Gaps

Whether using a decoupled wall or sound dampening panels, the next critical step is sealing. Any tiny cracks or openings compromise acoustic isolation and allow sound to leak through.

Use acoustic sealant to meticulously seal all seams, edges, penetrations and transitions.

After installing the drywall sheets for a decoupled wall, carefully seal the butted edges where each panel meets using acoustic sealant and joint tape. Run a smooth bead of sealant along the entire seam before embedding the special noise blocking fiber tape.

Feather out the sealant over the tape for maximum adhesion. Fill the screw holes used to attach the drywall as well for a flawless surface.

Pay special attention to sealing the wall perimeter for either the panel or drywall methods. Apply a continuous line of acoustic sealant where the wall meets ceilings, floors, and abutting walls.

Look for any transitions or edges allowing sound infiltration and fully caulk them. This seals the soundproofing envelope.

Inspect anywhere that utilities, vents, pipes or wiring penetrate the wall and apply sealant accordingly. Outlets and light switches often have sizeable gaps that leak noise if not sealed.

Insert acoustic putty pads around outlets to block sounds before replacing the plastic covers. Completely sealing every access point is imperative.

Do a final visual inspection for even hairline cracks or openings and dab sealant over them. Double check corners, behind trim, and around vents.

The goal is a 100% airtight wall that gives sound no entry point through framing seams, materials joints or around objects. Avoid overlooking minor gaps that could undo all your soundproofing efforts.

Step 6: Add Finishing Touches

With the intensive sound insulation work complete, conclude by returning the wall to its finished state. This includes moldings, paint, lighting, and any removed fixtures or decorations.

Use caution to avoid degrading sound isolation while enhancing aesthetics.

Reinstall electrical switch plates, registers, thermostats or other utilities that were removed during preparation using acoustic sealant around the edges. Be careful not to over-tighten screws and pierce the soundproofing underneath.

Avoid excess pressure on the wall materials.

Apply primer and paint to achieve the desired finished look. Use paint grade acoustic sealant for filling any nail holes or blemishes in molding and trim work.

Add baseboards, window trim, chair rails and other decorative elements to match the room. Just be sure not to fully penetrate the soundproofed wall behind – screws should not go all the way through the drywall into studs.

Finally, carefully rehang any pictures, shelves or mirrors removed initially using special soundproofing hanging brackets. This avoids creating new air leaks or rigid transmissions through the wall.

Step back and ensure the various finishing steps have not compromised noise blocking while restoring aesthetics.

Conclusion

Installing soundproofing is a detailed process requiring patience and diligence, but the payoff in noise reduction is immense.

With the proper materials installed correctly following our outlined steps, you can transform those annoyingly thin, noise-leaking walls into an effective barrier that dramatically cuts sound transmission between rooms.

Just remember that careful planning and prep work are crucial – identify the precise noise sources and pathways first before sealing vulnerabilities and installing sound-absorbing or dampening materials.

Leave no gaps unfilled, using specialized acoustic sealants anywhere noise could penetrate.

While the decoupled wall technique provides maximum noise blocking, sound dampening panels also work for predominantly airborne sounds. Whichever method you choose, be thorough, precise, and don’t cut corners.

Completing each step properly results in the peaceful quiet environment you desire. The difference in comfort and privacy from soundproofed walls is remarkable.

Your home will feel calmer, more relaxing, and you’ll no longer dread noise disruptions. With some diligent elbow grease, you can successfully transform those thin walls and start enjoying the blissful benefits of a quieter indoor sanctuary.