Have you ever walked into a recording studio and wondered why the walls look like they’re covered in egg cartons?

Or perhaps you’ve tried to DIY a home theater and ended up with a room that sounds like a tin can? The culprit—or the solution—could very well be acoustic foam.

This comprehensive guide aims to demystify acoustic foam, a misunderstood yet crucial element in sound management.

We’ll dive deep into its composition, effectiveness, limitations, and even explore alternative materials that can better serve your specific needs.

So, if you’ve ever puzzled over foam panels in studios or wondered how to elevate your home’s acoustics, you’re in the right place. Let’s dive into the nitty-gritty of acoustic foam.

What Exactly Is Acoustic Foam?

The term acoustic foam often conjures images of egg-crate-like material clinging to the walls of a recording studio.

While this imagery isn’t entirely off-base, it’s essential to delve deeper to understand what acoustic foam really is and, perhaps more importantly, what it is not.

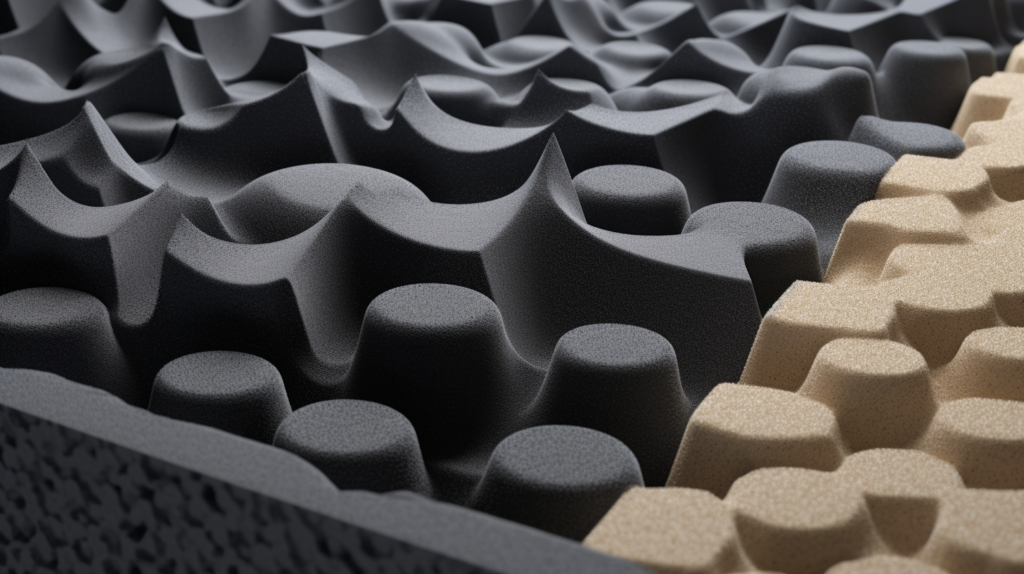

Acoustic foam is primarily composed of polyurethane, a polymer with a myriad of applications from industrial machinery to household furniture.

In the context of acoustic foam, polyurethane undergoes specific treatments to maximize its sound-absorbing properties.

Through meticulous engineering, the foam is designed with an open-cell structure.

This isn’t a coincidental attribute but a carefully planned feature that serves a critical purpose: maximizing the foam’s interaction with sound waves.

However, let’s set the record straight—acoustic foam is not a jack-of-all-trades in the world of acoustics. It has limitations, particularly when it comes to low-frequency sounds.

The open-cell structure that makes it so effective at absorbing high-frequency sounds is not as effective at tackling lower frequencies.

This is a crucial point that often gets buried in the marketing literature, leading to misunderstandings and, ultimately, less-than-optimal acoustic solutions.

How Does Acoustic Foam Work?

When we talk about the functionality of acoustic foam, we enter the realm of sound science—a fascinating interdisciplinary field that incorporates physics, engineering, and even a bit of psychology.

Sound, in its most basic form, is a series of pressure waves that propagate through a medium (usually air).

When these waves encounter a surface, they interact in one of three ways: absorption, reflection, or transmission.

Acoustic foam excels in the absorption category, primarily due to its porous, open-cell structure. This structure allows for a phenomenon known as porous absorption.

Simply put, porous absorption is the trapping of sound waves within a network of interconnected open cells.

When a sound wave hits an acoustic foam panel, the wave gets funneled into these open cells.

As the wave travels through this labyrinthine structure, it loses energy through a process known as thermo-viscous loss.

In layman’s terms, the sound wave’s energy dissipates as heat due to the friction against the foam cell walls.

This loss of energy results in a reduction of the sound wave’s amplitude, leading to decreased echo, reverberation, and sound reflection.

However, it’s crucial to reiterate a point here—acoustic foam is not universally effective across all sound frequencies.

It is far more effective at absorbing high-frequency sounds than low-frequency sounds.

This limitation is often not adequately discussed, leading to misapplications and dissatisfaction with the material’s performance.

The Limitations of Acoustic Foam

While acoustic foam has become somewhat of a staple in settings that require sound management, it’s important not to overlook its limitations.

One of the most prominent downsides is its relatively poor performance with low-frequency sounds.

Low-frequency sounds, such as deep bass notes, are not as easily absorbed by acoustic foam due to their longer wavelengths and higher energy.

These types of sounds often require materials with greater mass and density to effectively absorb them.

Another limitation to consider is the foam’s longevity and durability. Over time, acoustic foam can deteriorate, losing some of its effectiveness.

Environmental factors such as humidity and temperature can also affect its performance, which means it may not be the best choice for all climates or settings.

Finally, while acoustic foam is relatively easy to install, the outcome is often only as good as the installation itself.

A poorly executed installation can severely limit the material’s effectiveness, leading to unsatisfactory results.

Therefore, even though acoustic foam panels may come with adhesive backings or other simple installation methods, it’s essential to understand the acoustics of the space to ensure optimal placement.

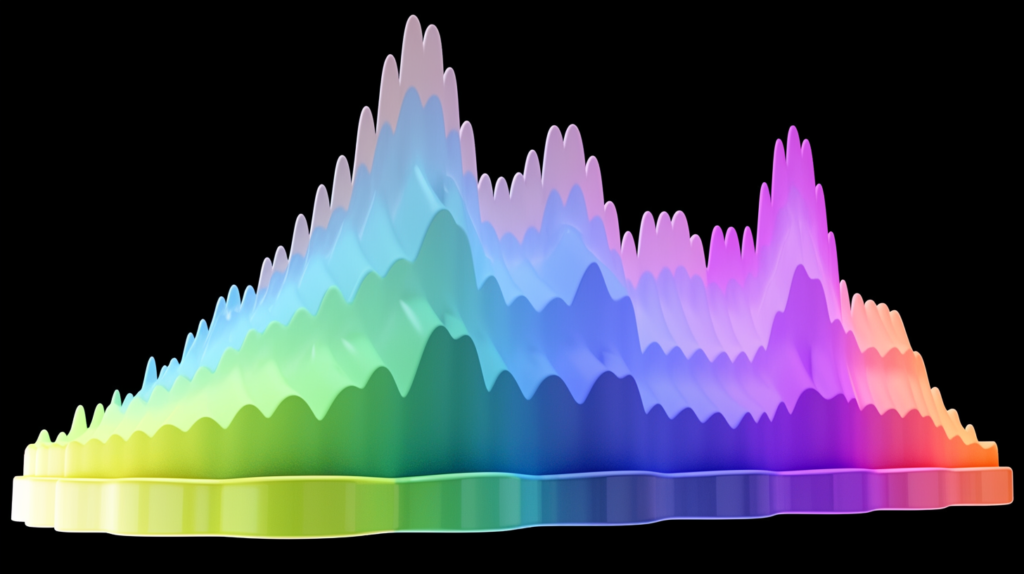

What Frequencies Can Acoustic Foam Absorb?

When discussing the effectiveness of acoustic foam, the frequency of sound is a critical factor that can’t be overlooked.

Sound frequencies are typically measured in Hertz (Hz), and they can range from extremely low (think of the rumbling of thunder) to very high (like the shrill of a whistle).

High-Frequency Sounds

Acoustic foam is generally most effective at absorbing high-frequency sounds, which can range from approximately 2,000 Hz to 20,000 Hz.

This makes it particularly useful in environments where clarity of speech or vocal recording is a priority, such as in a podcast studio or a call center.

High-frequency noises like the hissing of the letter ‘s’ or the tapping of a keyboard are effectively minimized by acoustic foam.

Mid-Frequency Sounds

Mid-frequency sounds, often ranging between 500 Hz and 2,000 Hz, can also be managed reasonably well by most acoustic foam types. However, it’s crucial to note that the foam’s effectiveness tends to decrease as we move toward the lower end of this range.

Comparative Materials: Mineral Wool, Fiberglass, and Polyester Acoustic Panels

Given the limitations of acoustic foam, it’s beneficial to explore alternative materials that may offer different advantages.

Mineral wool, for example, is a material made from spun mineral fibers and is especially effective at absorbing low-frequency sounds.

It’s a denser material compared to acoustic foam, making it a good option for more comprehensive sound management.

Fiberglass is another alternative that offers good sound absorption properties. It’s a lighter material compared to mineral wool but is still effective for a broad range of frequencies.

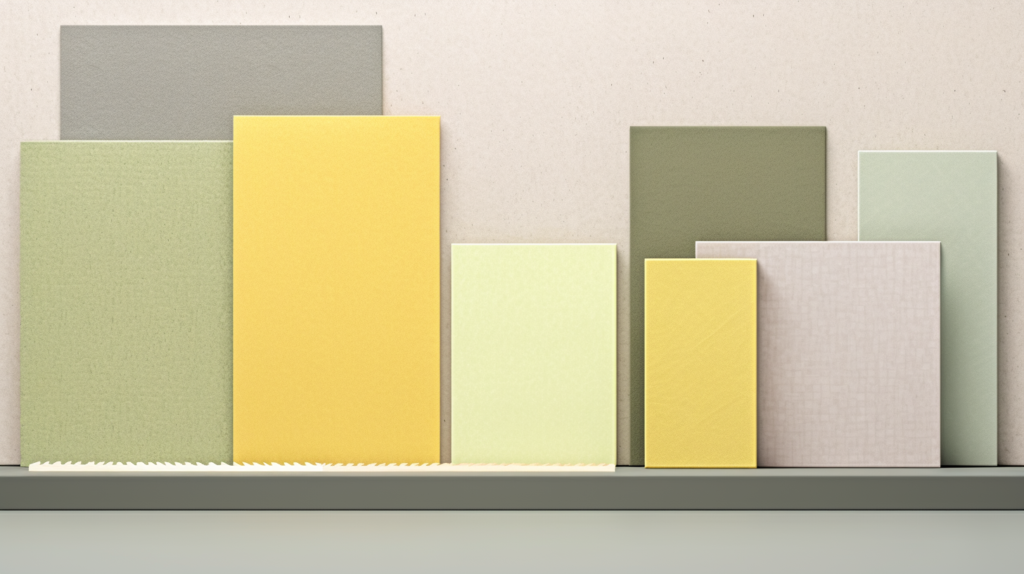

Mineral wool and fiberglass can be converted to become an acoustic panel by placing them into fabric-wrapped acoustic panels.

Polyester acoustic panels provide another interesting option. These panels are often more rigid compared to foam, offering excellent sound absorption properties while also being aesthetically versatile.

They come in various colors and designs, which means they can serve a dual purpose—improving the acoustics while also enhancing the aesthetics of a space.

Where Is Acoustic Foam Most Effective?

Understanding the limitations and alternatives to acoustic foam can help us better identify where it is most effectively used.

Acoustic foam excels in settings that primarily deal with high-frequency sounds.

These could be recording studios focused on vocal recordings, podcasting studios, or even some home theater setups where speech clarity is a primary concern.

However, it’s critical to understand that acoustic foam is often just one part of a broader sound management strategy.

In professional settings, it’s common to see a mix of materials used to treat a space’s acoustics.

For example, a recording studio might use acoustic foam for the walls but incorporate bass traps made from denser materials like mineral wool to handle the low-frequency sounds.

Similarly, in a home theater setup, while acoustic foam may be used on the walls or ceiling, it might be complemented by polyester acoustic panels or even diffusers to manage sound reflection and provide a more balanced auditory experience.

How Do You Install Acoustic Foam?

When it comes to the installation of acoustic foam, the devil is in the details.

While it may seem straightforward to stick foam panels onto a wall, achieving the desired acoustic environment requires a far more nuanced approach.

One of the first steps in the installation process is identifying the sound reflection points within the room.

These are specific areas where sound waves are likely to bounce back, creating echoes and reverberations. Accurate identification of these points is crucial for the effective placement of acoustic foam.

Beyond the location, the orientation of the foam panels also matters. Acoustic foam often comes in various shapes like wedges, pyramids, or even custom designs.

The shape of the foam not only influences its aesthetic appeal but also its functional capability to absorb sound.

Therefore, understanding the nuances of each shape and how it interacts with sound waves is vital for optimal installation.

Moreover, the thickness of the foam plays a significant role in its sound-absorbing capabilities.

Thicker panels are generally more effective at absorbing lower frequencies, although they still may not be as effective as denser materials like mineral wool.

Therefore, choosing the right thickness is another critical consideration during the installation process.

Conclusion

As we come to the end of this exhaustive guide, it’s evident that while acoustic foam holds a certain allure in the sphere of sound management, it’s not a one-size-fits-all solution.

Its engineering brilliance in tackling high-frequency sounds is counterbalanced by its limitations in absorbing low-frequency noises.

Therefore, a nuanced approach is essential for anyone seeking effective acoustic solutions, whether for a professional recording studio or a cozy home theater.

We’ve explored the science behind acoustic foam, its advantages, and its limitations.

We’ve also delved into alternative materials like mineral wool, fiberglass, and polyester acoustic panels, each offering a distinct set of benefits and drawbacks.

The key takeaway is that a well-rounded acoustic strategy often involves a mix of these materials, carefully chosen to suit the specific requirements of a space.

So, the next time you find yourself mesmerized by the claims of acoustic foam’s sound-absorbing prowess, remember that it’s just one piece of a larger acoustic puzzle.

By understanding the nuances and making educated choices, you can create an auditory environment that is not just pleasing to the ears but also tailored to meet your unique needs.

Thank you for joining us on this deep dive into the world of acoustic foam and sound management. We hope this guide serves as a valuable resource for your future acoustic endeavors.