Walking into a room full of harsh echoes and excessive reverb can be disorienting and uncomfortable. Controlling acoustics is crucial for quality listening experiences.

Acoustic foam panels provide an effective way to treat high frequency noise issues by absorbing sound rather than reflecting it.

Strategic use of these affordable and customizable panels can greatly improve room acoustics.

But how exactly do acoustic foam panels work?

What are the benefits of using them?

And what are their limitations?

This article explores the details behind effectively utilizing acoustic foam for taming sound reflections and reverberation.

What Are Acoustic Foam Panels?

Acoustic foam panels are made from sound-absorbing foam that can help reduce high frequency noise and echo in a room.

They are installed on walls and ceilings. Acoustic foam is porous and open-celled so it can effectively absorb high frequency sound energy.

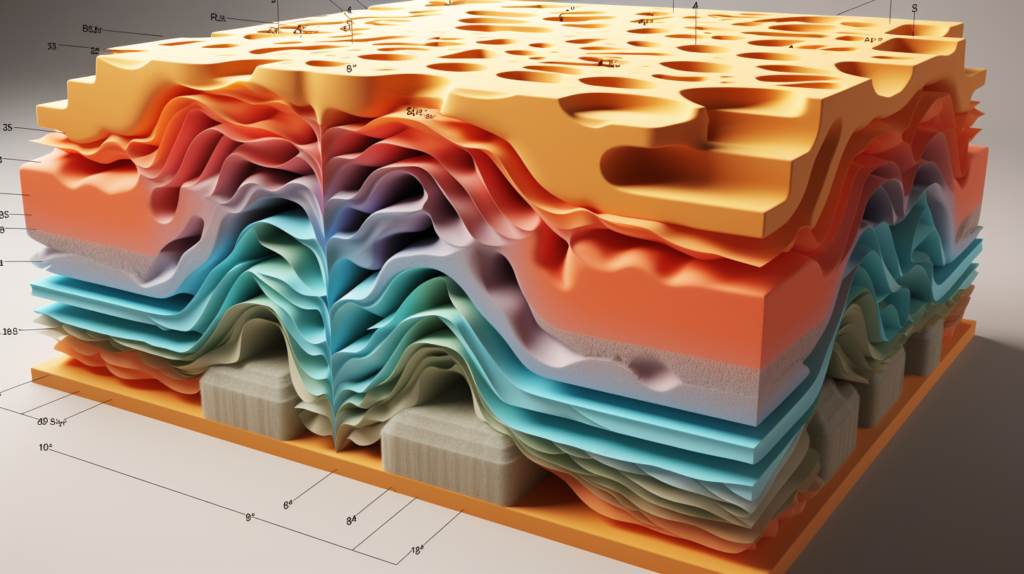

The foam contains lots of tiny pores and passages that allow sound waves to penetrate into the material. As the sound enters the foam, the vibrational energy is converted to heat due to the friction and resistance within the porous structure.

This transforms the acoustic energy into thermal energy instead of reflecting it back into the room.

Acoustic foam panels, also known as soundproofing foam or acoustic treatment, are customizable panels that can be placed around a room to help absorb and reduce noise pollution specifically in the high frequency range.

They come in different shapes, sizes, colors and densities and are an affordable and effective acoustic treatment option to treat issues with echoes, reverberation and other high pitch sounds bouncing around a room.

Acoustic foam tiles are a popular way to improve sound quality and acoustics. The panels are typically 1-4 inches thick and can be installed on walls, ceilings, and even free-standing portable baffles.

They provide a simple way to add sound absorption and reduce harsh reflections.

Acoustic foam panels work by absorbing high frequency sound waves rather than reflecting them, reducing echo and reverberation in a room. The porous structure allows the foam to dissipate the sound energy.

Foam Absorption of High Frequency Sound Waves

The open cell structure and porous surface of acoustic foam panels allows them to effectively absorb high frequency sound waves.

Whenever high pitch sound hits the foam, the sound energy is absorbed by the foam and converted into heat energy instead of being reflected back into the room.

This absorption and dissipation of the high frequency sound reduces and minimizes the echo and reverberation caused by these airborne sounds bouncing off hard surfaces like walls, ceilings or windows.

As the high frequency sound waves hit the acoustic foam, they pass into the open porous structure of the foam material.

The foam’s soft, flexible polyurethane skeleton contains lots of passageways that allow the sound waves to penetrate deep into the material.

As the sound enters the foam, the vibrations cause friction with the cell walls which converts the acoustical energy into a very small amount of heat.

This transformation of energy prevents the waves from reflecting back into the room.

However, the small foam cells are not large enough to properly absorb lower frequency, deeper bass sounds which end up continuing to reverberate around the room.

How Do Acoustic Foam Panels Work?

Acoustic foam panels work by absorbing high frequency sound waves rather than reflecting them.

The foam material contains an open, porous structure with lots of interconnecting pores and passages. This allows sound waves to easily enter into the foam rather than bouncing off the surface.

As high frequency sound encounters the acoustic foam panel, it passes into the porous structure of the material.

The soft, flexible foam contains many tiny pockets and channels that enable the sound waves to penetrate deep into the foam.

As the sound enters these passages, the vibrations of the waves cause friction with the cell walls in the foam.

This friction converts the acoustic energy into a miniscule amount of heat. This transformation from acoustical energy to thermal energy is what prevents the high frequency waves from being reflected back out into the room.

Instead, the sound gets dissipated as heat within the form itself. This absorption and dissipation of high frequency sound waves by the acoustic foam is what reduces echoes and reverberation caused by these sounds bouncing around the room.

Strategically placing acoustic foam panels in key locations allows them to absorb and control high pitch sounds right at the points where they would initially reflect.

This is how acoustic foam panels are able to effectively improve room acoustics by minimizing high frequency reflections and reverberation.

What Are Acoustic Foam Panels Made Of?

Acoustic foam panels are primarily made of polyurethane foam, a synthetic material known for its flexibility and porous structure.

The open-cell nature of polyurethane foam makes it highly effective at absorbing sound, particularly in the high-frequency range.

This material is chosen for its unique ability to convert sound energy into heat energy through friction within its cellular structure, effectively minimizing echoes and reverberations.

Different densities and thicknesses of polyurethane foam can be engineered to fine-tune the material’s acoustic behavior.

These variations enable customization to meet the specific needs of a room or space, whether it’s a home studio, an office, or a commercial setting.

It’s also important to note that many acoustic foam panels are treated with fire-retardant materials to meet safety standards and building codes.

This is an essential consideration for using foam panels in a variety of environments, from recording studios to public spaces.

Additionally, acoustic foam panels often come in various surface patterns, such as wedges, pyramids, or egg-crate shapes.

These patterns not only add an aesthetic element but also serve a functional purpose by increasing the surface area of the foam, thereby enhancing its sound-absorbing properties.

Benefits of Using Acoustic Foam Panels

Strategically placing acoustic foam panels around a room provides a number of benefits for controlling high frequency noise pollution and improving sound quality.

The foam absorbs and reduces echoes as well as the reverberation caused by high pitch sounds bouncing around on flat, hard surfaces.

High frequency noises from outside the room can also be minimized as the foam absorbs the sound rather than reflecting it.

The customizable sizes and shapes make it easy to place panels exactly where needed to target high frequency issues in a room.

Acoustic foam is also relatively inexpensive compared to many other commercial soundproofing products and acoustic treatments.

By installing acoustic foam panels on walls and ceilings, the foam will absorb the high frequency sound right at the points of first reflection.

This prevents flutter echoes and reduces reverb caused by multiple sound wave reflections in a room.

Unwanted reflections off glass, tile, hardwood, and other rigid surfaces get turned into heat energy by the foam so they do not continue propagating unwanted noise pollution within the space.

Voice frequencies and other mid-high pitch sounds can be effectively controlled with strategic foam placement to improve overall sound quality.

Foam Panels Improve Room Acoustics and Absorb High Frequencies

Strategically placing acoustic foam panels around a room provides a number of benefits for controlling high frequency noise pollution and improving sound quality.

The foam absorbs and reduces echoes as well as the reverberation caused by high pitch sounds bouncing around on flat, hard surfaces.

High frequency noises from outside the room can also be minimized as the foam absorbs the sound rather than reflecting it.

The customizable sizes and shapes make it easy to place panels exactly where needed to target high frequency issues in a room.

Acoustic foam is also relatively inexpensive compared to many other commercial soundproofing products and acoustic treatments.

By installing acoustic foam panels on walls and ceilings, the foam will absorb the high frequency sound right at the points of first reflection.

This prevents flutter echoes and reduces reverb caused by multiple sound wave reflections in a room.

Unwanted reflections off glass, tile, hardwood, and other rigid surfaces get turned into heat energy by the foam so they do not continue propagating unwanted noise pollution within the space.

Voice frequencies and other mid-high pitch sounds can be effectively controlled with strategic foam placement to improve overall sound quality.

In home studios, recording studios, or other environments where audio quality is critical, foam panels help tame excessive reverb that colors and muddies the sound.

The foam cleans up the acoustics so engineers and musicians can better monitor mixes and recordings.

For home theaters, reducing high frequency reflections creates a clearer soundstage for dialog, music and effects.

In offices, foam absorbs unwanted chatter, equipment noise and parallel conversations to improve concentration.

Optimal Acoustic Foam Panel Placement

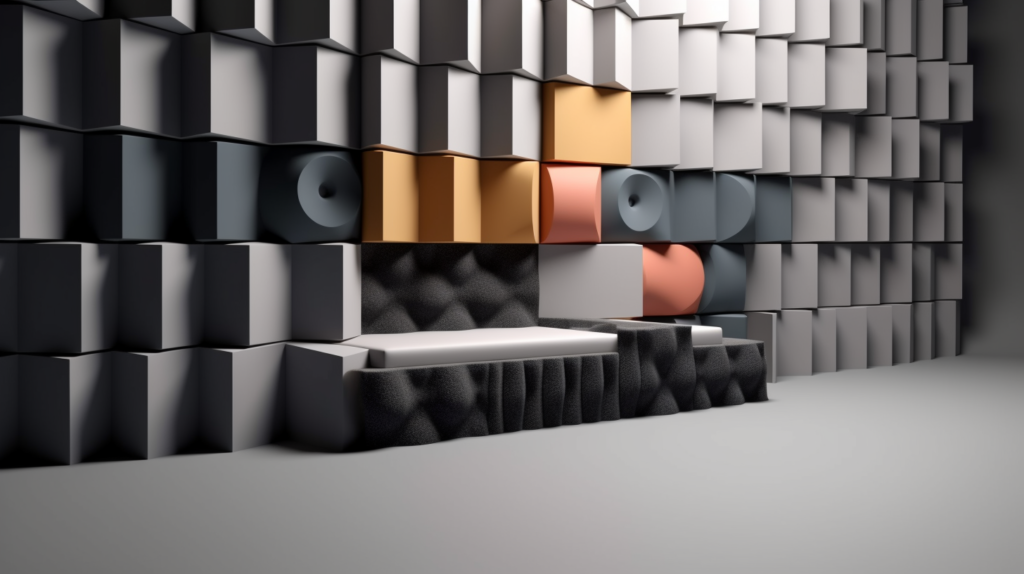

Proper placement of acoustic foam panels is important to maximize their effectiveness at absorbing high frequency sound reflections.

Identifying the key points that sound first hits and bounces can allow strategic positioning to treat issues.

Strategic Positioning for High Frequency Absorption

To get the maximum benefit for controlling high frequency sound, acoustic foam panels should be installed in strategic locations around a room.

Placing panels at the points of first reflection allows the foam to absorb high pitch sound waves right as they initially bounce off walls.

Installing foam panels on the ceiling can treat sounds from overhead and absorb downward propagating high frequencies before they reverberate around the room.

Panels placed behind speakers can help absorb and prevent harsh high frequency sounds emitted from the rear of the speaker from bouncing off the wall back at the listener.

And foam panels behind seating areas can absorb forward-projecting treble and vocals before being reflected back.

Identifying the first reflection points on walls and placing acoustic foam panels at those locations is crucial for reducing flutter echo and absorbing early reflections before they bounce around the room.

First reflection points are where sound from speakers or noise sources first hits a wall then reflects to the listener position. Installing foam here provides major sonic improvements.

Overhead reflection points should also be treated as sound from speakers and ambient noise hits the ceiling and can reflect down.

Placing foam above mix/mastering positions or theater seating is beneficial.

For home studios, it’s ideal to strategically place foam panels on the walls to the left and right of the mix position.

This absorbs the stereo image properly. Foam behind monitors and speakers prevents harsh reflected sound contaminating the direct audio.

And additional foam panels on the rear wall and ceiling further absorb sound. For optimal absorption, adhering the panels tightly with adhesive maximizes acoustic contact.

Tips for Using Acoustic Foam Panels

There are some useful tips and techniques for getting the most out of acoustic foam panels when treating a room. Methods like layering, combining foam with broadband absorbers, using fire rated foam and proper adhesive mounting can all improve performance.

Methods to Improve Foam’s High Frequency Performance

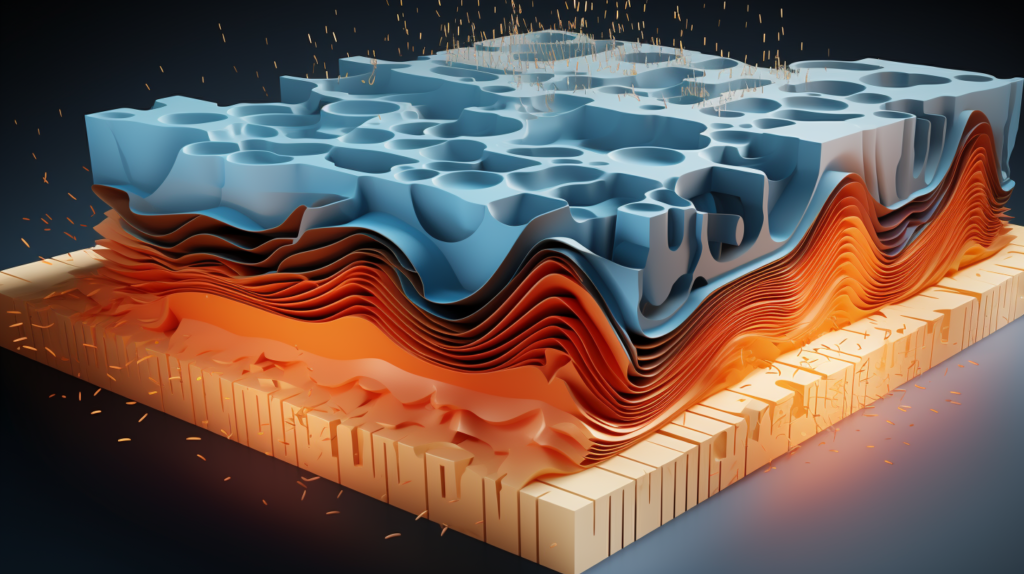

Layering multiple acoustic foam panels together increases the overall thickness and density which improves high frequency sound absorption.

Combining foam with bass traps or other broadband acoustic treatments can help cover both high and low frequency ranges.

Fire rated foam should be used in public spaces for safety.

And adhering the panels directly to walls and ceilings rather than just pinning them ensures the foam makes maximum contact for absorbing high pitch sound waves.

Layering foam panels boosts absorption by increasing the depth of material sound must travel into, allowing more even dissipation.

Some people also angle or stagger the layered panels to diffuse reflections. Mixing different foam densities, wedge types, and depths can help widen the absorption range.

Portable baffles covered in foam are great for temporary setups or rentals.

To make the foam adhere properly, specialized mounting adhesive made for polyurethane foams should be used rather than typical construction adhesives.

The adhesive should be applied in vertical stripes spaced a few inches apart to allow the material to breathe. Proper installation ensures the foam makes tight contact for maximum sound absorption.

Fire rated acoustic foam meeting certain codes and regulations must be used in public spaces.

Untreated foam can be flammable so fire retardant polyurethane or polyethylene options treated to meet local ordinance are safer options for studios, theaters and offices.

Low Frequency Limitations of Acoustic Foam

While acoustic foam panels are great for absorbing high frequency reflections, they do have some limitations when it comes to lower frequencies and bass sounds. The small foam pores cannot effectively trap longer low frequency waves.

Why Foam Doesn’t Work Well for Lower Frequencies

While acoustic foam panels work well for absorbing and reducing high frequency reflections, they do have some limitations when it comes to lower frequencies and soundproofing.

The small foam cells cannot properly absorb lower frequency bass sounds, allowing them to continue reverberating around the room.

The foam also does not block or decouple sound transmission between rooms or insulate against external noise intrusion.

Some find the eclectic look of foam panels visually unappealing. And plain foam without a fire retardant treatment can be flammable if it is not properly fire rated.

The typical open cell size of acoustic foam panels ranges from 0.1 inches to 1 inch in diameter.

This is optimized to absorb mid to high frequency sounds above 500 Hz.

Lower frequencies and bass have much longer sound waves of 10 ft or more, which are too large to be properly broken up and dissipated by the foam material.

So the low end continues bouncing around unchecked. Combining foam with traditional fiberglass insulation or bass traps can help absorb fuller frequency ranges.

In addition, acoustic foam does nothing to block or prevent sound transmission. The soft, porous foam cannot impede sound waves from passing through walls or windows.

Loud music, voices, traffic noise, etc can intrude right through the foam.

Effective sound blocking requires much denser materials like mass loaded vinyl, plywood, insulation and drywall. So foam alone cannot soundproof rooms or prevent noise transfer.

Is Acoustic Foam Effective for Soundproofing?

Soundproofing requires both controlling reflections and absorbing sound as well as blocking transmission of noise from other spaces. Acoustic foam helps with absorption but not isolation.

Foam Primarily Treats High Frequencies, Not Lows

Acoustic foam panels primarily absorb high frequency echoes and reverberation. They do not effectively block lower frequency noise transmission or fully soundproof rooms.

Strategic placement can help reduce high pitch reflections but additional soundproofing is needed for lows.

While useful for controlling high frequency reflections and echo, acoustic foam panels alone do not provide effective soundproofing for a room.

The foam does not block or prevent sound waves from transmitting through walls or insulate a space from external noise.

True soundproofing requires denser mass loaded materials like MLV, insulation, drywall or specialized wall panels to decouple rooms and add mass.

So while foam panels can improve sound quality by absorbing high frequency reflections, additional sound blocking treatments are required for proper sound isolation from lower frequencies and exterior noise.

To properly soundproof a room, both absorption like foam and transmission blocking techniques need to be incorporated.

Mass loaded vinyl sheets or soundproof drywall can be layered on top of existing walls to improve transmission loss.

Green glue adhesive between layers also helps decouple surfaces. Sealants around outlets and joints prevent flanking noise.

Combined together, these treatments address the full frequency spectrum for noise control.

So foam panels serve an important role in taming reflections and reverb, while heavy mass and sealed rooms prevent sound intruding from other noisy spaces.

Conclusion

In summary, acoustic foam panels are an effective and affordable way to treat issues with high frequency noise pollution, echo, and excessive reverberation in a room.

The porous foam material absorbs and dissipates high pitch sounds through friction, preventing continued reflections.

Strategic placement at first reflection points and other key areas allows the foam to control flutter echo and reverb.

While useful for treating highs, acoustic foam does have limitations when it comes to low frequencies and true soundproofing.

To properly block noise transmission and isolate spaces, additional dense mass loaded materials must be incorporated.

But for the important task of taming high frequency reflections and improving room acoustics, acoustic foam panels provide an accessible and customizable solution.

Used properly, foam treatment can greatly enhance sound quality and listening environments.