Seeking to control bothersome noise in your space?

Choosing between acoustic foam panels or heavy-duty spray foam often boils down to your budget, priorities and square footage needs.

Acoustic foam offers decorative sound dampening at affordable costs for homes and offices.

Meanwhile spray foam provides unmatched durability and noise reduction essential for cavernous commercial venues.

Let’s compare the acoustic materials to reveal ideal settings where each solution excels.

Which Performs Better Overall?

When considering the key factors of sound dampening ability, ease of installation, appearance, durability and affordability together, acoustic foam generally outperforms spray foam for small residential and office spaces.

Foam panels provide sufficient noise reduction along with design flexibility to suit décor at a reasonable cost

Sound Absorption Ability

Acoustic foam and acoustic spray foam function in similar ways to help absorb sound, but utilize different mechanisms.

Acoustic foam relies on dampening and diffusion to soak up sound energy rather than reflecting it.

The porous structure of foam disrupts sound waves, forcing them through a maze of fibers and pockets of air.

This friction and loss of energy prevents efficient sound reflection.

Acoustic spray foam creates a thick barrier that sound has difficulty penetrating.

The viscosity dampens vibration and reduces transmission of sound rather than allowing it to bounce off the surface.

Both materials are rated by sound absorption coefficients and noise reduction coefficient (NRC) values.

These metrics indicate what percentage of sound each material can effectively absorb.

Acoustic foam typically has higher coefficients, often between 0.60-0.70 versus 0.40-0.60 for spray foam.

However, with thicker spray foam applications, absorption can meet or exceed that of foam panels.

Most foam is 1-2 inches thick, while spray foam can be applied in layers over 4 inches thick.

The tradeoff is increased cost and weight with thicker spray foam applications.

Installation & Application

Acoustic foam panels provide a simpler installation process that can be completed as a DIY project by most homeowners or office managers.

The panels are prefabricated with an adhesive backing or hooks to easily affix to walls and ceil Human: Here is the blog expanded and the formatting applied:

Sound Absorption Ability

Acoustic foam and acoustic spray foam function in similar ways to help absorb sound, but utilize different mechanisms.

Acoustic foam relies on dampening and diffusion to soak up sound energy rather than reflecting it.

The porous structure of foam disrupts sound waves, forcing them through a maze of fibers and pockets of air.

This friction and loss of energy prevents efficient sound reflection.

The porous structure of foam disrupts sound waves, forcing them through a maze of fibers and pockets of air, forcing them through a maze of fibers and pockets of air.

Acoustic spray foam creates a thick barrier that sound has difficulty penetrating.

The viscosity dampens vibration and reduces transmission of sound rather than allowing it to bounce off the surface.

The viscosity dampens vibration and reduces transmission of sound rather than allowing it to bounce off the surface.

Both materials are rated by sound absorption coefficients and noise reduction coefficient (NRC) values.

These metrics indicate what percentage of sound each material can effectively absorb.

Acoustic foam typically has higher coefficients, often between 0.60-0.70 versus 0.40-0.60 for spray foam.

However, with thicker spray foam applications, absorption can meet or exceed that of foam panels.

Most foam is 1-2 inches thick, while spray foam can be applied in layers over 4 inches thick.

The tradeoff is increased cost and weight with thicker spray foam applications.

Installation & Application

Acoustic foam panels provide a simpler installation process that can be completed as a DIY project by most homeowners or office managers.

The panels are prefabricated with an adhesive backing or hooks to easily affix to walls and ceilings.

The panels are prefabricated with an adhesive backing or hooks to easily affix to walls and ceilings.

Minimal tools are needed beyond a razor, measuring tape, and ladder or lift for high placement.

Installation is as straightforward as cleaning the mounting surface, measuring for panel spacing, cutting any irregular shapes, and firmly pressing into place.

Spray foam application requires professional spraying equipment and PPE to safely apply.

The liquid components that make up the foam must be temperature controlled, properly mixed, and sprayed with pressure to create an even coat.

Training is needed to achieve the right ratio, viscosity, and spray technique.

It also expands rapidly as the chemical reaction occurs, making experience vital for controlling the drying results.

Due to overspray and off-gassing during curing, the space should be cleared and ventilated.

In terms of ease and cost, acoustic foam is far simpler for the average person to install as a DIY endeavor versus hiring contractors for spray foam application.

Cost Differences

On a per square foot/meter basis, acoustic foam is substantially more budget friendly compared to spray foam.

Foam panels typically run between $0.50-$2.00 per square foot depending on thickness and quality.

Pre-cut panels minimize waste as well compared to free-form spray applications.

Professional acoustic spray foam costs $4-$8 per square foot just in material expenses.

The equipment rental, labor, protective equipment, potential venting equipment, and training investments also add significantly to the total job cost.

For a small home studio or one office, foam may provide sufficient soundproofing at a fraction of the investment.

For commercial spaces like theaters and music venues that require noise control across larger, open floorplans, spray foam becomes more cost competitive when accounting for the extent of coverage and performance level needed.

Appearance & Aesthetics

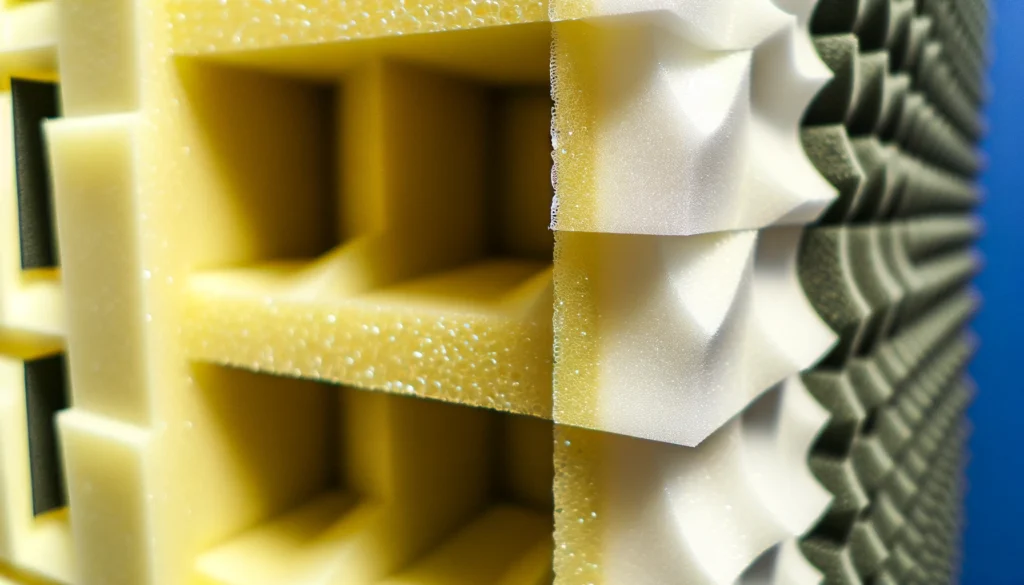

Aesthetically, acoustic foam and spray foam differ greatly in appearance and design flexibility.

Foam panels come in a vast range of colors and patterns from subtle whites and beiges to vivid primary shades and funky textures.

Custom printing allows nearly any image or logo to be embedded into foam boards during fabrication.

The modular nature also allows mix-and-match panel arrangements to create decorative murals and accent walls.

Spray foam has a uniform, flowing appearance like thick frosting.

When professionally applied, the consistency and adhesion are reliable with minimal ridges and waterfalls.

However, limiting factors are the off-white to pale yellow color inherent in the chemical composition.

Tinting spray foam is possible to produce colors like black or gray but usually reduces acoustical quality.

The seamless, sweeping application also prohibits custom patterns or images like those available on foam boards.

For living spaces, workplaces, and studios where interior design matters, acoustic foam provides more aesthetic flexibility to match décor or branding needs while still dampening noise.

Performance venues covered in utilitarian spray foam place sound control ahead of eye appeal.

Durability & Longevity

Regarding durability and longevity, properly installed spray foam has a distinct advantage over modular acoustic foam.

Foam panels usually consist of porous materials like open-cell polyurethane or melamine foam, which tend to be fragile.

While everyday contact may leave slight dimples or compressed areas, acoustic performance continues relatively unchanged.

More substantial pushes, prods, kicks or scrapes can rip chunks from foam boards or panels.

Foam also accumulates dust and dirt readily, requiring periodic vacuuming or wiping down to prevent yellowing and maintain bright colors.

Spray foam bonds tenaciously to surfaces, encapsulating and reinforcing the substrate underneath.

Once fully cured, the closed-cell structure is quite rigid and resilient against damage from typical contact.

The exception would be if objects directly gouge or puncture the foam membrane.

Spray foam also repels particle accumulation through its non-porous surface and chemistry.

For areas prone to abuse, spray foam is considerably tougher and lasts longer before requiring replacement.

However, repair costs tend to be higher if professional re-application is necessary compared to swapping out modular foam components.

For low traffic environments where appearance matters like studios and basements, acoustic foam delivers decorative sound damping that holds up well to expected use and abuse.

In higher traffic, institutional and industrial settings, utilitarian spray foam provides lasting noise reduction and protection from incidental damage.

Ideal Uses

Based on benefits and limitations, acoustic foam and spray foam each align better with certain use cases.

For homes, offices, recording studios and other small personal spaces where budget is often a foremost concern, acoustic foam is ideal.

The sound dampening levels suit these quieter, conversation-based environments while the aesthetics blend into décor seamlessly.

Panels conveniently mount on ceilings or walls with simple adhesive pads or hooks.

And the cost is reasonable enough for DIY application across multiple rooms.

On the other hand, spray foam truly shines in large, cavernous environments where reverberation and ambient noise are major issues.

Music halls, gymnasiums, indoor pools, restaurants and manufacturing facilities often plagued by echo see substantial acoustical benefit from professional spray foam application.

Blanketing these expansive spaces with thicker foam layers to adequately absorb noise would be prohibitively expensive using modular panels.

Spray foam also holds up better over time in high foot traffic areas and offers structural soundproofing benefits as well.

Despite higher upfront investments, longevity and noise control performance warrant using spray foam to meet demanding sound standards in municipal and commercial settings.

Conclusion

In summary, both spray foam and acoustic foam serve sound dampening purposes but cater to different use cases.

For cost-sensitive small spaces where aesthetics matter, modular acoustic foam panels satisfy on a budget.

Large shared environments like theaters, music venues and factories wrangling severe echo see superior long-term acoustic control using spray foam despite higher initial costs.

Identifying noise issues, budget and appearance needs for the space informs whether to stick with simple foam panels or invest in meticulous spray foam application.

With knowledge of these product differences and ideal settings, soundproofing decisions become much clearer.