As urbanization accelerates, modern life is characterized by a never-ending drone of machinery, traffic, construction, and countless other noises permeating our lived experience.

Achieving peace and quiet has become an uphill battle.

Effective soundproofing allows us to regain control over our acoustic environments—to mute the cacophony of the outside world and amplify the tranquil sounds we prefer.

When executed strategically through the careful selection and application of appropriate materials and techniques, soundproofing has the power to transform dissonant spaces into personalized havens of respite.

However, misconceptions abound regarding ideal soundproofing solutions, with many believing common thermal insulators like Styrofoam will suffice.

As we will explore, materials effective for insulation do not necessarily excel at containing sound.

To craft truly silent spaces, we must delve deeper into the science of acoustics and leverage materials engineered specifically to conquer noise.

Understanding Soundproofing

In an age where urbanization is accelerating, and the hum of modern life is pervasive, the importance of soundproofing becomes paramount.

The very essence of soundproofing transcends the mere act of blocking noise.

It is about crafting an auditory environment, a haven of sorts, where the sounds we wish to hear are crisp and clear, and the ones we don’t are muted or entirely absent.

Soundproofing is an intricate dance of physics and materials science.

At its most basic, it’s the manipulation of sound waves, either by blocking, reflecting, absorbing, or diffusing them.

These sound waves, borne from vibrations in the air, are energy in motion, and they can be both a boon and a bane.

A melodious tune or a loved one’s laughter is as much a product of sound waves as the jarring honk of a car or the incessant drone of construction machinery.

To navigate the world of soundproofing effectively, one must first grapple with its two primary facets: sound absorption and sound insulation.

Sound absorption concerns the quality of sound within a space. For instance, in a large empty hall, a spoken word might echo multiple times, creating a reverberation that muddies the original sound.

Absorptive materials work to mitigate this effect, soaking up the sound waves and preventing multiple reflections. They essentially ‘clean up’ the sound within a space.

On the flip side, sound insulation is about containment.

It’s about ensuring that the cacophony of the outer world doesn’t invade our personal spaces and that our activities don’t unduly disturb others.

It’s a barrier, a shield that stands between spaces, allowing them to maintain their auditory independence.

Both these facets, while interconnected, require distinct approaches. The materials, techniques, and considerations for one might not necessarily apply to the other.

Hence, embarking on a soundproofing endeavor requires a clear understanding of the end goal: is it to improve internal acoustics, keep external noise at bay, or both?

What Is Styrofoam?

In the pantheon of modern materials, styrofoam occupies a unique position. It’s both ubiquitous and somewhat misunderstood.

At its core, styrofoam is a type of plastic, expanded polystyrene foam to be precise.

The name ‘styrofoam’ is so popular that it’s often used generically, much like ‘kleenex’ for tissues, but it’s actually a brand name owned by Dow Chemical Company.

Styrofoam’s primary claim to fame is its incredible insulating properties against temperature.

Its structure, comprising millions of tiny closed cells filled with air, makes it a poor conductor of heat.

This means that it’s excellent at keeping heat out (or in) and is why it’s often used in building insulation and even coffee cups.

However, when we shift our focus from thermal properties to acoustic ones, the efficacy of styrofoam becomes a topic of debate.

While it’s undeniable that a material that can block heat transfer might have some impact on sound transfer, the mechanisms by which heat and sound travel and interact with materials are distinct.

Common Misconceptions About Styrofoam And Soundproofing

The world of building materials is vast and varied. However, few materials have garnered as many misconceptions as styrofoam, especially in the realm of soundproofing.

A significant reason for this is its stellar performance in thermal insulation. It’s easy to assume that a material that’s so effective against heat might be equally formidable against sound.

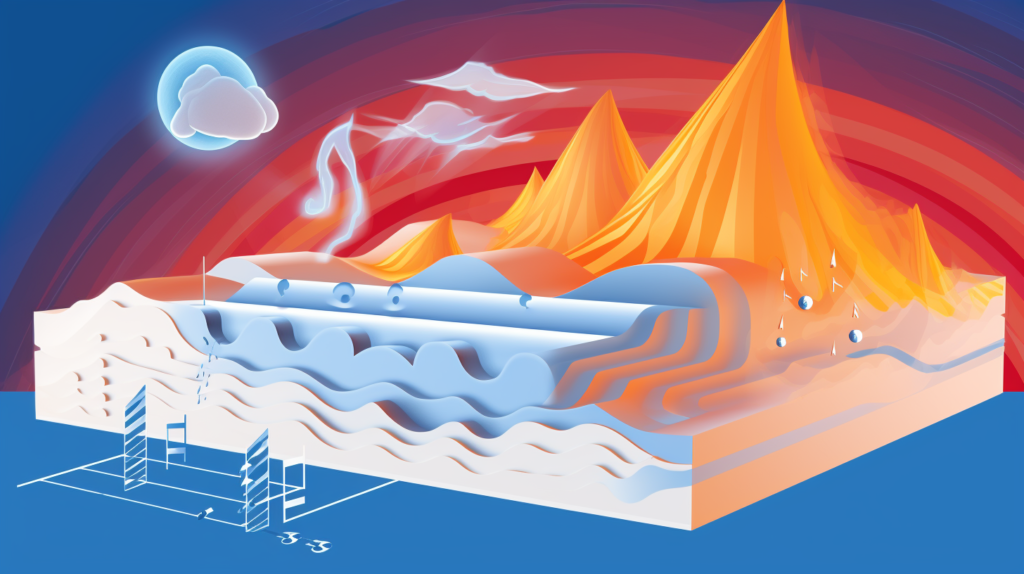

However, this assumption misses a fundamental point: heat and sound, while both forms of energy, don’t behave the same way.

Heat transfer, especially in solids like walls, occurs primarily through conduction. The trapped air in styrofoam makes it a poor conductor, thereby making it an excellent insulator.

Sound, on the other hand, travels through vibrations in a medium, be it solid, liquid, or gas. The way materials interact with these vibrations determines their soundproofing efficacy.

Another misconception is that any form of barrier will automatically soundproof a space.

This notion can lead to disappointment when one realizes that merely adding a layer of styrofoam to a wall or ceiling doesn’t provide the desired quiet.

The Inefficiencies Of Styrofoam In Soundproofing

When we delve deep into the world of acoustics, certain truths become evident. One of these truths is the principle that mass stops sound.

Sound waves, when they encounter a barrier, exert force on it. A heavier, denser barrier is harder to move, making it more resistant to sound transmission.

Styrofoam, for all its merits, is lightweight. It lacks the heft required to effectively combat sound waves, especially those at lower frequencies.

While its cellular structure can diffuse some sound, diffusion isn’t a robust soundproofing mechanism.

Diffusion scatters sound waves, reducing the direct force of the sound, but it doesn’t prevent the sound from passing through.

For a more analytical perspective, one can turn to the Sound Transmission Class (STC) ratings.

In simple terms, the STC rating gives us a measure of how well a material can reduce sound transmission.

The nuances of this rating are profound, with different materials showing varied efficacy at different frequencies.

When subjected to this analysis, styrofoam’s limitations in soundproofing become evident. Its STC ratings, especially when compared to dedicated soundproofing materials, are on the lower side.

Alternatives To Styrofoam For Soundproofing

In the quest to find effective soundproofing solutions, styrofoam’s limitations prompt a deeper exploration of alternatives.

The contemporary market is abundant with materials meticulously engineered to mitigate the multifaceted challenges presented by sound.

Burton Acoustix Soundproofing Panels are a testament to innovation in the acoustic world.

Crafted from Nitrile Butadiene Rubber and felt, these panels are not only effective but also environmentally friendly.

Their unique composition offers robust soundproofing capabilities, making them ideal for spaces where sound containment is a priority yet tearing off walls are not a choice.

Whether it’s a home theater, office space, or a studio, these panels ensure that sound stays where it’s meant to be.

Fiberglass Insulation, commonly associated with construction, has commendable soundproofing credentials.

The fibrous nature of this insulation excels at ensnaring sound waves.

These waves, as they journey through the maze-like structure of the fibers, get progressively drained of their energy, leading to absorption and dampening.

Additionally, fiberglass insulation pulls double duty by also providing thermal insulation, making it an invaluable dual-purpose solution.

Rockwool Insulation bears similarities to fiberglass but originates from molten rock that’s spun into delicate fibers.

Its intrinsic density surpasses that of fiberglass, granting it a slight edge in soundproofing capabilities.

Parallel to fiberglass, Rockwool also offers thermal insulation. Its resistance to fire further elevates its stature, making it a preferred material in various construction endeavors.

Mass Loaded Vinyl (MLV) has carved a niche for itself in soundproofing. As the name suggests, it’s essentially vinyl, a type of plastic, that’s been endowed with additional mass, typically via metal particles.

This augmented mass transforms MLV into a formidable barrier against sound. Its inherent flexibility broadens its applications, making it a go-to choice for walls, floors, ceilings, and even encasing pipes.

Its versatility and effectiveness make MLV a stalwart in soundproofing solutions.

Resilient Channels and Decoupling Techniques, though seemingly intricate, are foundational in professional-grade soundproofing.

The underlying principle is elegantly simple: by instigating a gap or ‘decoupling’ a wall or ceiling from its finishing layer, sound waves face a challenge.

As they endeavor to traverse this gap, they’re deprived of energy. Drawing an analogy, it’s akin to intermittently pushing a swing; the swing never reaches its full potential.

Resilient channels, fashioned from metal, facilitate the creation of this decoupled space, ensuring an indirect, energy-depleting path for sound, thereby minimizing its transmission.

Practical Tips For Those Considering Serious Soundproofing

Soundproofing, while rooted in science, isn’t a rigid discipline. Different spaces have unique challenges, and what works in one situation might not in another.

As such, a strategic approach, underpinned by research and planning, is vital.

Firstly, Assess The Noise Source. Is it traffic noise, loud neighbors, or maybe airborne noise from an adjacent apartment?

Identifying the primary noise sources will guide the choice of materials and techniques.

For instance, if low-frequency noise from trucks or heavy machinery is the issue, then materials and methods effective against these frequencies should be prioritized.

Secondly, Understand The Space. A basement has different soundproofing challenges compared to an attic.

Factors like ventilation, existing insulation, and even the materials used in construction play a role in how sound travels and can be managed.

Don’t Overlook The Details. Sound, much like water, will find the path of least resistance. Even the smallest gaps, like those around doors, windows, or outlets, can undermine the most robust soundproofing measures.

Sealants, weather stripping, and even simple draft stoppers can be invaluable in these scenarios.

Combine Materials And Techniques. Relying on a single solution is seldom the best approach.

A combination, like MLV coupled with resilient channels and topped with acoustic foam, can address a broader range of frequencies and offer comprehensive soundproofing.

Lastly, Seek Expertise. The world of acoustics is vast and nuanced. While DIY solutions can be effective, professional guidance can ensure that efforts are targeted and resources are used optimally.

Whether it’s a consultation or a full-fledged soundproofing project, expert insights can be the difference between success and mediocrity.

Advanced Soundproofing Techniques Simplified

Soundproofing might seem intricate, but at its core, the techniques are straightforward. Here’s a distilled guide to the primary methods:

1. Add Mass: The fundamental principle in soundproofing is that more mass equates to better sound blocking. By adding additional layers or denser materials to walls, ceilings, or floors, you create a formidable barrier against noise. This is the domain where materials like Mass Loaded Vinyl truly come into their own, offering significant weight without excessive thickness.

2. Decouple: Think of this as creating an air gap. By separating two sides of a structure, like a wall, you’re forcing the sound to traverse an air gap, which weakens it. This technique is effective in preventing the direct transfer of sound from one side of the structure to the other.

3. Drywall Layering: Once you’ve added mass and created a decoupled structure, covering it up with drywall provides an additional layer of defense. Drywall, especially when used in multiple layers, further impedes the path of sound, enhancing the overall soundproofing.

4. Use Green Glue: As you layer materials, an adhesive is required. Green Glue isn’t just any adhesive; it’s specifically designed for soundproofing. It not only bonds materials but also acts as a damping compound, converting some of the sound energy into heat, especially effective against those pesky low-frequency noises.

5. Seal with Acoustic Sealant: After all the layers are in place, the final step is to ensure there are no gaps or leaks. Sound can exploit even the tiniest of openings. An acoustic sealant is tailored to seal these gaps, ensuring a fully soundproofed space.

By following this simple sequence, one can achieve a robust soundproofing solution, ensuring peace and quiet in any environment.

Conclusion

In the crescendo of modern life, where every moment is underscored by a myriad of sounds, the ability to orchestrate silence becomes an art form.

Soundproofing is not merely about erecting barriers; it’s about curating our auditory landscapes, painting a canvas where the notes of tranquility shine through and the cacophonies fade into obscurity.

From understanding the very nature of sound to unraveling the intricacies of materials and techniques, our journey through soundproofing is a testament to human ingenuity.

The drive to create sanctuaries of serenity amidst the clamor showcases our innate desire for harmony.

With the right tools, knowledge, and a sprinkle of determination, we can transform our spaces into bastions of peace, where every sound is a choice, not an imposition.

As we step into a future where urban sprawls expand and spaces intertwine, the symphony of silence that soundproofing offers will be the melody many will seek.

So, armed with the knowledge and insights shared, may you be the maestro of your own quietude, crafting spaces that resonate with calm, clarity, and comfort.