Excessive reverb and echo can ruin the audio experience, but can acoustic foam save the day?

Acoustic foam provides an affordable and straightforward way to absorb problematic sound reflections that lead to unwanted reverb and echo issues.

Let’s dive into the details on how acoustic foam works to tame noise and create clearer acoustic spaces.

Can Acoustic Foam Effectively Stop Reverb and Echo?

In short, yes acoustic foam can effectively minimize problematic reverb/echo when properly implemented.

By absorbing rather than reflecting sound waves that cause unwanted noise buildup, acoustic foam reduces amplification and continuation of scattered sounds.

We’ll explore specifics below on optimal foam selection and placement for your situation.

What Is Acoustic Foam?

Acoustic foam is a special type of foam that is designed to absorb sound waves and reduce reverberation and echo in rooms.

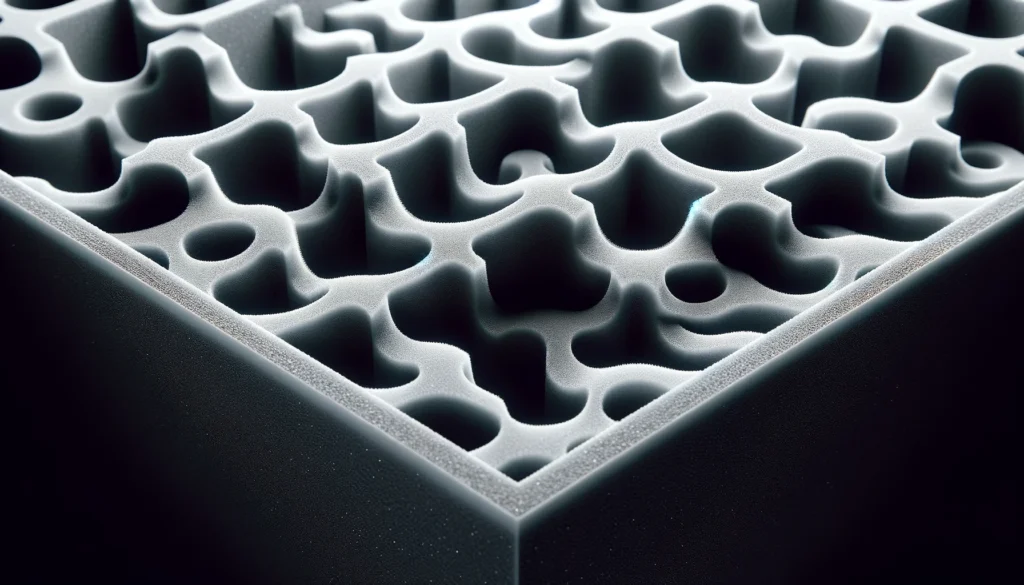

It is commonly made out of various types of open cell foam materials that enable sound waves to penetrate into the foam and lose energy.

The open and porous structure of acoustic foam provides a lot of surface area for absorbing sound waves, unlike hard flat surfaces which can cause sound waves to bounce and reverberate.

By absorbing sound waves, acoustic foam can minimize reflected sound waves that cause unwanted reverb and echo.

Acoustic foam is generally effective at absorbing mid and high frequencies but often performs less well at absorbing low bass frequencies.

This is due to the inherent challenges of absorbing long low-frequency waves.

The thickness and density of the foam will impact how effective it is at absorbing various frequencies.

Some specialty acoustic foams claim to have properties making them competitive at absorbing a wider range of frequencies.

In general, the goal of acoustic foam is to control excessive reverb and echo that can negatively impact sound quality in spaces like audio recording studios and home theaters.

This is accomplished by strategically placing acoustic foam panels on sound reflective surfaces to absorb and disperse sound waves rather than letting them repeatedly reflect off hard surfaces.

How Acoustic Foam Reduces Reverb and Echo

Acoustic foam reduces reverb and echo through a simple physical process.

When sound waves from a source like a speaker enter the open cell structure of the foam, the motion of the air molecules that carry the sound vibrates the cell walls of the foam.

This causes frictional losses which convert some of the acoustic energy into very small amounts of heat.

This loss of energy reduces the sound waves’ amplitude and reduces reverberation in the room.

The porous and reticulated nature of the foam provides more varied angles for the sound waves to penetrate, as opposed to a flat smooth surface.

This increased interaction maximizes absorption.

Having varying cell shapes and sizes provides a broader spectrum of absorption to handle a wider range of wavelengths.

The more open space in the foam, the more dramatic the energy absorption can be.

In technical terms, the coefficient of sound absorption indicates the fraction of random incident sound energy absorbed versus reflected.

A material with a higher coefficient is better at damping sound waves rather than reflecting them back into a room.

Acoustic foam can achieve sound absorption coefficients of 0.6 or higher in the mid to high audio spectrum.

The degree of reverb and echo reduction depends significantly on the thickness and density rating of the foam.

In general, thicker and less dense foam absorbs more sound due to increased pathway lengths for oscillating soundwaves and less impedance mismatch between air and material.

However, density contributes to absorption effectiveness so finding the right balance is key in acoustic foam engineering.

Using Acoustic Foam Panels to Control Reverb/Echo

Acoustic foam is available in modular paneling that absorbs unwanted room noise that contributes to reverb and echo issues.

These foam panels can be installed on walls and ceilings using adhesive.

Strategic placement is necessary to address major reflective surfaces that exacerbate reverberation.

Rooms with lots of bare hard surfaces require more foam panels than rooms with carpeting, curtains and other sound absorptive features.

The number and placement of panels needed is determined by room dimensions, reflective surface areas, and intended usage.

Recording control rooms and home theaters, for example, often require above average absorption to achieve reverb times under 0.4 seconds across most frequencies.

For reference, an empty room may have a reverb time of over 1 second.

In small rooms like basement studios and offices, acoustic foam can make a significant difference controlling excess reverb and echo.

The minimal thickness can provide meaningful absorption.

For larger spaces, acoustic foam has some limitations for low frequency control without exceedingly thick installation.

Maximum benefit also requires coverage over a meaningful percentage of the key reflective area.

Human vocal and musical recordings often aim for some reverb and liveness, so foam shouldn’t eliminate all reflections.

Thus finding the right balance through strategic placement offers optimal acoustic conditions.

Portable acoustic foam panels provide flexibility in rooms needing variable setups.

Acoustic Foam vs Other Sound Absorption Options

Acoustic foam has some advantages and disadvantages compared to other acoustical treatment options on the market:

Fabric Covered Fiberglass/Mineral Wool Panels

Fiberglass and mineral wool absorbers wrapped in fabric offer superb broadband absorption down into lower bass frequencies compared with typical foam products.

The depth required can be just 2-4 inches for performance exceeding acoustic foam foot for foot.

However, fabric panels come at a higher cost per square foot normally.

Installation may also require wood frames and createsmess requiring plastic sheeting as protection.

In contrast, modular acoustic foam pieces have clean edges and stick directly to almost any clean permanent surface.

Foam panels come in fun colors and dramatic geometric shapes in many cases, enabling interior design freedom.

The fabric skin over fiberglass limits decorative flexibility more noticeably.

For users valuing easy visual enhancement and bold soundproofing upgrades, foam products carry strong appeal.

Polyester Insulation Panels Behind Fabric

An even more cost effective DIY acoustic panel option utilizes standard polyester/fiberfill insulation sandwiched between a fabric layer and some backing material.

If space allows for a total panel thickness up to 4 inches or beyond, polyester can achieve impressive low frequency damping due to increased depth for sound waves penetration.

However, material choices and construction quality impact end performance.

For those on a tight budget or wanting to experiment before installing permanent professional built panels, starter DIY panels show promise.

Yet consistency and fire safety remain concerns lacking factory quality control.

Melamine and polyurethane based acoustic foams offer known, engineered acoustic properties in safe Class A fire rated products.

For many home and business owners, acoustic foam strikes the best value balance.

Key Considerations for Acoustic Foam Effectiveness

Several factors determine the real world effectiveness of acoustic foam installations:

Foam Thickness

Acoustic foam commonly comes in thickness ranging from just under 1 inch to over 4 inches.

In general, thicker foam allows improved sound absorption across more frequencies.

However, limitations exist even for thicker foam primarily related to controlling bass frequencies with longer wavelengths.

Finding the right thickness per application helps balance cost, aesthetics, and acoustic objectives.

Foam Density Rating

Typically specified in pounds per cubic food, the foam’s density or bulk density influences sound absorption capabilities.

Less dense foam around 0.75 to 1.0 lbs/cubic foot works well for home studios and offices.

Ultra light foam may lack durability while ultra dense foam may better suit industrial noise reduction but costs more.

Density choice depends on budget, installation goals and environment.

Foam Material Type

Many acoustic foams today consist of either a melamine based foam or a polyether/polyurethane open cell foam.

Melamine foam offers high heat resistance and sound absorption ratings of 0.8 or above but does not withstand outdoor installation.

Polyether and polyurethane foam comes in an array of densities and properties with good acoustic capability as well though usually a bit less than melamine.

More exotic blends exist too.

Placement Strategy

The quantity of foam matters less than optimal placement for addressing reflected sound and room resonance hotspots.

Full wall and ceiling coverage often overkills acoustics and budget.

Using a sound level meter to map problematic areas or establishing tracking microphone placement guides tactical panel installation.

Groupings at reflection points of speaker monitoring positions increases effectiveness.

regularly.

Strategic placement resolves more issues per panel versus scattered distribution.

In summary, understanding basics of how acoustic foam absorbs sound coupled with leveraging key specifications and room data allows for control of excessive reverb and echo.

Acoustic foam constitutes a relatively affordable and effective noise and echo control option suitable for many residential and commercial spaces.

Paired with additional sound blocking techniques, rooms take on dramatically improved sonic character benefiting working, listening and learning environments.

While acoustic foam comes with realistic performance limitations, especially at lower frequencies, correct product selection and placement provides evident acoustic upgrades.

With some careful planning and testing, bothersome sound reflections yield to interior acoustical treatments.

Conclusion

In conclusion, acoustic foam offers a budget-friendly means for controlling excessive reverb and echo issues.

Leveraging appropriate foam products by targeting key sound reflection points in a room provides evident sonic improvements.

While realistic limitations exist, especially impacting lower bass frequencies, strategic acoustic foam installation enhances many residential and commercial spaces.

Give acoustic foam consideration when aiming for cleaner and clearer audio environments.