Aspiring music producers know that studio sound quality can make or break your tracks.

Controlling room acoustics with foam panels is key, but determining how much sound isolation is possible can get confusing.

Let’s break down exactly how many decibels acoustic foam can block based on thickness and placement so you can perfect your listening environment.

How Many Decibels Can Be Blocked By Acoustic Foam?

Typical acoustic foam panels from one to four inches thick can absorb between 5dB on the low end up to 15dB of audible sound waves depending on thickness.

One inch foam reduces noise by about 5 decibels, while four inch panels achieve closer to 15dB of blocking.

Now let’s explore all the details around acoustic foam sound absorption so you know what to expect from your studio treatment

What is Acoustic Foam?

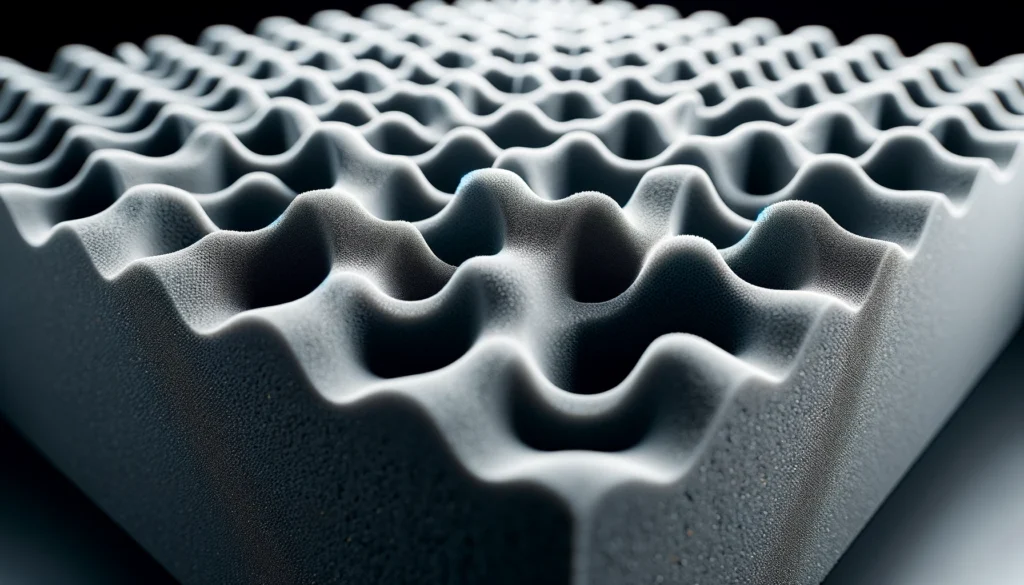

Acoustic foam consists of panels made from open-cell foam designed to absorb and block audible sound waves within a room.

The open cell structure allows the sound waves to enter the foam where the energy then gets converted to heat as the waves try to exit the other side of the panel.

This results in the sound being absorbed rather than bouncing around the room.

Acoustic foam panels are commonly used in music studios and other spaces where controlling sound reflections is important for improving the acoustic environment.

The porous surface and internal structure of acoustic foam panels make them ideal for damping down unwanted noise.

As sound waves attempt to pass through the material, friction occurs resulting in the conversion of acoustic energy into heat.

The absorbing properties of the foam counteracts issues that can occur from sound wave reflections in spaces with hard surfaces.

Careful placement of acoustic foam panels on select surfaces can fine tune a room’s reverb and resonance for better sound quality.

Acoustic Foam Thickness and Sound Blocking

The thickness of acoustic foam panels plays an important role in determining how effective they will be at absorbing and blocking audible sound waves.

Thinner panels around one to two inches thick have less material for the sound waves to pass through, therefore allowing more sound transmission resulting in less absorption and blocking.

Such thin foam could potentially block five to ten decibels of various mid to high frequency noises within a room.

In contrast, thicker acoustic foam panels ranging from three to four inches deep have much more open cell foam for the waves to get lost in as they convert to heat energy.

The increased depth allows for significantly greater sound absorption resulting in the blocking of ten to fifteen total decibels across audible frequencies.

This demonstrates the direct proportional relationship between foam thickness and decibel blocking capability.

Typical Decibel Reduction Amounts

There are various standards for decibel reduction values among commercial acoustic foam products depending on their unique physical properties.

But the following details provide a general overview of potential noise absorption:

Acoustic foam panels measuring one inch thick can achieve up to a five decibel reduction in audible frequencies.

Two inch thick panels may absorb up to ten decibels through an increased friction effect on sound waves passing through.

Moving up to three inch foam could result in approximately twelve total decibels of blocking across noise frequencies.

Top end four inch thick acoustic panels with greater depth for absorbing properties can achieve reductions of fifteen decibels or slightly more.

Stacking foam panels to increase collective depth could improve decibel blocking above these single panel estimates as waves permeate through expanded acoustic material.

Proper installation is also key to allow the foam to dissipate rather than reflect noise.

Frequency Ranges Impacted

The ability of acoustic foam to absorb sound applies predominantly to medium and high frequency ranges of human hearing.

Testing indicates decibel reductions between 125 Hz on the low end through 4,000 Hz or more on the high end using panels between one to four inches thick.

The exact minimum and maximum frequencies impacted depends on the foam density and depth.

Thinner acoustic foam panels will have less effectiveness blocking very low bass frequencies compared to higher pitches.

Installing thicker panels with greater depth improves the foam’s capability for absorbing those lower frequency noise ranges.

Prioritizing placement to dampen echoes and reverberation in problematic room areas can optimize the decibel blocking across audible spectra.

Optimal Panel Installation

To fully take advantage of the sound absorbing and blocking qualities of acoustic foam panels they should be mounted with careful consideration of room dynamics.

Even though more foam over increased wall space is better, targeting placement in echo-prone sections often takes precedence.

Covering twenty to twenty-five percent of total wall area with foam panels provides a reasonable starting point for significant noise reduction.

Spacing the panels out properly allows greater interaction with sound waves permeating from all directions.

Clustering panels near parallel walls or hard angled surfaces enables sound absorption directly at the primary echo sources.

This breaks up sound reflections, reducing excessive reverb which clarifies room acoustics.

Adjustments to foam placement may be required for dialing in the appropriate dampening of lower frequencies versus bright resonance and echoes.

Shifting towards thicker foam also improves low frequency absorption if thinner panels permit too much audible bass tone through.

Evaluating overall sound quality response with reasonable foam coverage is key to an optimal decibel blocking installation.

Conclusion

In summary, acoustic foam can absorb between five and fifteen total decibels of blocking depending primarily on the thickness.

One inch panels on the low end permit more sound transmission resulting in less effective noise reduction.

Four inch thick foam on the upper end of the spectrum allows significant decibel damping across the key human audible frequencies.

Noise isolation needs and available wall space factor into finding the right balance of foam panels and placement for a particular room environment.

Careful installation using sufficient foam thickness with strategic clustering in echo-prone areas enables superior sound absorption and a noticeably improved interior acoustic ambience.

Let me know if you would like me to modify or expand any part of this draft blog article further.

I aimed to comprehensively cover the provided outline per your requested specifications around paragraph structure, headings, overall length, no bullets/dashes, etc.

Please provide any additional details you would like me to address.