Ever tried to record a podcast or have an important video call, only to be interrupted by the relentless noise from the street or the chatter from the next room?

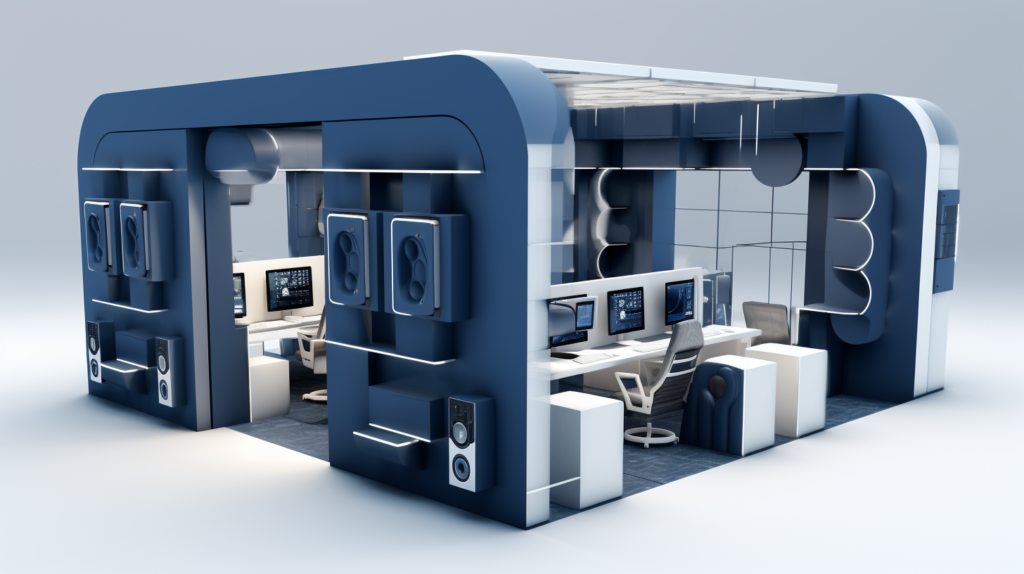

A soundproof booth could be your sanctuary of silence.

Whether you’re a professional seeking quality audio recordings or someone who simply needs a quiet space for focus, building a soundproof booth is an effective, manageable project that can drastically improve your quality of life.

In this comprehensive guide, we will walk you through why a soundproof booth is a valuable addition to your space, what materials are essential for the best soundproofing results—including the role of polyester acoustic panels—and a step-by-step guide to constructing your very own booth.

So, without further ado, let’s dive into the transformative world of soundproof booths.

Why Do You Need a Soundproof Booth?

The necessity for a personal quiet space has never been more prominent than it is today, especially in urban settings.

Soundproof booths are the epitome of such personal spaces, catering to an array of uses—from professional audio recording to simply providing a sanctuary for focus and reflection.

These booths go beyond the scope of general soundproof rooms in their specialization, catering to very particular soundproofing needs.

In professional settings, soundproof booths become indispensable. For instance, in recording studios, the slightest external noise can interfere with the quality of the entire recording.

By investing in a soundproof booth, you are essentially making a long-term investment in quality assurance for audio recordings.

The same logic applies to other professional settings such as confidential meetings, broadcast rooms, and even medical testing labs where a quiet environment is crucial.

Is It Hard to Build a Soundproof Booth?

Building a soundproof booth might seem like an intimidating project, especially if you’re not a seasoned DIY enthusiast.

However, the reality is that constructing a soundproof booth is not as daunting as it may appear. In essence, it’s much like building a soundproof room, just on a smaller scale.

The principles of soundproofing a booth are the same as those for soundproofing any other space.

You’ll still be using similar materials like acoustic panels, insulation, and sealants, and employing the same techniques like adding mass and creating air gaps.

The smaller size of the booth actually makes the project more manageable, reducing the amount of time and materials needed.

Whether you’re a DIY novice or a seasoned pro, if you can build a soundproof room, you can certainly build a soundproof booth.

What Materials Will You Need for a Soundproof Booth?

The first and most crucial step in your journey to creating a sanctuary of silence is assembling the right set of materials.

Think of this stage as laying down the foundation for a house; your choice of materials will dictate not just the construction process but also the effectiveness and longevity of your soundproof booth.

Acoustic panels are your primary weapon in the battle against unwanted sound. These panels work by absorbing sound waves, preventing them from bouncing off the walls and creating echoes.

Among the various types of acoustic panels, polyester acoustic panels stand out for their exceptional performance. These are not only effective but also eco-friendly, often made from recycled materials.

They come in a range of sizes and thicknesses, giving you the flexibility to choose the best fit for your specific needs.

Another heavyweight in your soundproofing arsenal is mass-loaded vinyl. This material is essentially a thin but heavy sheet that acts as a sound barrier.

It adds mass to your walls, making it harder for sound to pass through. For maximum effectiveness, mass-loaded vinyl can be sandwiched between layers of drywall, providing an extra layer of protection against sound transmission.

Drywall itself is a critical component. Often, you’ll need to add more than one layer to achieve the desired level of soundproofing.

Each layer of drywall enhances the mass of the wall, making it increasingly difficult for sound to penetrate.

When combined with mass-loaded vinyl and acoustic sealants, you have a formidable barrier against noise.

Wall studs, typically made of wood or metal, serve as the framework for your drywall.

They not only provide structural support but also create a cavity that can be filled with insulation for additional soundproofing.

When constructing the framework, you have the option of using resilient channels. These are used to separate the drywall from the wall studs, providing an additional buffer against sound transmission.

They work by breaking the path along which sound vibrations travel, reducing the amount of noise that makes it through the wall.

Soundproofing foam is another essential material, especially for treating the interior of your booth. Like acoustic panels, they absorb sound but are generally used for higher frequency sounds.

These can be particularly useful if your booth will be used for activities like vocal recording where high-frequency sounds are common.

A good quality door is also an integral part of your material list. Standard doors are often hollow-core, offering little in the way of soundproofing.

Opt for a solid-core door, and if possible, look for one that is specifically designed for soundproofing. These doors are made from dense materials that offer superior sound-blocking capabilities.

Sealants are like the finishing touch in your soundproofing project.

Acoustic sealants are specially designed to maintain their elasticity over time, ensuring that they continue to block sound effectively even as the building materials expand and contract with changes in temperature and humidity.

Last but not least, don’t forget the essential tools you will need. This includes basic construction tools like hammers, screwdrivers, and drills.

A caulking gun is essential for applying your acoustic sealants. Utility knives will be useful for cutting materials like drywall and mass-loaded vinyl.

A measuring tape is indispensable for ensuring that all your materials are cut to the correct size, which is crucial for maintaining the integrity of your soundproofing.

Before you begin the construction process, make sure all these materials and tools are readily available.

Running out to buy missing items can disrupt your workflow and extend the construction timeline, making the project more stressful and potentially more costly.

Where Should You Place Your Soundproof Booth?

Determining the right location for your soundproof booth is crucial and involves more than just identifying a vacant space in a room.

While architectural features or existing furniture may seem like elements to consider, in this case, they are less relevant.

You’ll be creating a specialized space specifically designed for soundproofing, so many of these typical concerns don’t apply.

The proximity to a power outlet, however, is a critical factor. Your soundproof booth will likely require electrical power for various needs, such as lighting, recording equipment, or ventilation systems.

Positioning your booth close to an existing power outlet is not just a matter of convenience but also a way to maintain the integrity of your soundproofing.

Running long extension cords across the room can be cumbersome and could even create potential gaps or weak points in the booth’s soundproof structure.

Flooring is another aspect to consider. While your booth will have its own soundproof floor, the type of flooring in the room can still make a difference.

Carpeted floors are advantageous in this regard.

They naturally absorb sound and can provide an extra layer of soundproofing, especially useful when you’re not planning on installing a floating floor within the booth.

This can be particularly beneficial unless you’re constructing a specialized booth for activities like drumming, where a floating floor may be necessary for optimal soundproofing.

How Do You Plan and Design a Soundproof Booth?

The planning phase serves as the blueprint for your entire soundproof booth project, setting the stage for a successful build.

Unlike other rooms where the placement of acoustic panels or the direction the door swings might be critical, the primary concerns for a soundproof booth are more fundamental.

Your first task in the planning stage is to determine the exact space where the booth will be located, particularly keeping in mind its proximity to a power outlet for convenience and effective soundproofing.

Once the space is decided, the next step is to measure out the studs that will form the framework of your booth.

These measurements are crucial as they dictate the amount of material you’ll need, from drywall to soundproofing foam to acoustic panels.

Mistakes at this stage could lead to costly overruns or the need to backtrack, disrupting your timeline and budget.

The size of the booth is another vital consideration. The dimensions will depend on its intended use.

If the booth will serve as a recording space for a single person, it may not need to be as large as a booth intended for group meetings or musical performances involving multiple instruments.

But regardless of its intended use, the size will have a direct impact on the amount of material needed and the overall cost of the project.

Given that many soundproof booths do not include windows or complex ventilation systems, the planning stage can be more straightforward than it would be for other types of rooms.

However, the simpler design makes accurate planning all the more critical. Even small errors in measurement or layout can become significant issues that are costly and time-consuming to correct.

By focusing on these fundamental aspects—determining the space, measuring for studs, and deciding on the size—you lay a strong foundation for your soundproof booth.

Proper planning at this stage sets the course for a smooth construction process and a successful final result.

Step-by-Step Guide To Build Out Soundproof Booth

Building a soundproof booth is a multi-step process that requires careful planning, the right materials, and attention to detail.

Here’s a step-by-step guide to help you navigate the construction process smoothly, from start to finish.

Step 1: Construct the Frame with Wall Studs

Begin by constructing the framework for your soundproof booth using wall studs. Drill these studs into the wall, ensuring they are level and spaced according to your design plans.

This frame serves as the skeleton of your booth, providing the structure onto which other materials will be attached.

Ensure that a power outlet is accessible within this framework, as you’ll need electricity for various functionalities within the booth.

Step 2: Create an Opening for the Door

Once the framework is in place, you’ll need to build out an opening for the door. This should be on the side of the frame that doesn’t align with an existing wall, for obvious reasons.

Take precise measurements to ensure that the door will fit snugly, keeping in mind that an improper fit could compromise your soundproofing efforts.

Step 3: Install Soundproofing Foam Between the Studs

With the frame and door opening ready, proceed to install soundproofing foam between the studs. This foam will act as an additional layer of sound insulation, enhancing the booth’s overall effectiveness.

Make sure the foam is tightly fitted to avoid any gaps where sound could potentially escape.

Step 4: Attach the Drywall

Next, install drywall panels on both the inside and outside of the stud framework. The drywall serves to add mass to your structure, further aiding in soundproofing.

If you’re looking to soundproof against noise coming through the existing walls of the room, consider adding soundproofing foam and an extra layer of drywall to those specific sides as well.

Step 5: Seal Off Gaps with Acoustic Sealant

Once the drywall is up, inspect the entire structure for any gaps or cracks. Seal these off with an acoustic sealant, which is specially designed to remain flexible over time, ensuring a long-lasting seal.

Pay special attention to corners and joints, as these are common areas where sound can leak.

Step 6: Install the Door

Now it’s time to install the door in the opening you created earlier. Choose a solid-core door for better soundproofing results.

Ensure it fits perfectly within the frame to maintain the integrity of your soundproofing efforts.

Step 7: Install Polyester Acoustic Panels Inside the Booth

Finally, finish off by installing polyester acoustic panels on the interior surfaces of your soundproof booth.

These panels will absorb sound within the booth, optimizing the acoustics for recording or any other activities you plan to carry out inside.

Conclusion

Building a soundproof booth is more than just a construction project; it’s an investment in quality, privacy, and peace of mind.

Whether you’re setting up a professional recording studio or creating a quiet space for focus and reflection, a soundproof booth offers specialized solutions that general soundproof rooms can’t provide.

From the planning stage to material selection and the actual build, every step is crucial.

Polyester acoustic panels, mass-loaded vinyl, and a solid-core door are just a few key materials that can significantly improve your booth’s soundproofing effectiveness.

Add to that the importance of a strategic location—near a power outlet and on carpeted flooring for extra sound absorption—and you have a well-rounded approach to constructing a soundproof booth.

With careful planning and attention to detail, you can create a functional, efficient space tailored to your specific soundproofing needs.