Is your loud aspirator driving your family crazy or ruining your recordings?

Soundproofing your aspirator is straightforward when you target the main noise sources.

Let’s dive into the common sounds to isolate and how to contain them effectively.

Why Soundproof Your Aspirator?

An aspirator can generate a considerable amount of noise that may disrupt your daily life or work. The main noise sources include the motor, fan, vibrating hoses, and contact with walls and floors.

Soundproofing your aspirator can provide several benefits that make it worth the effort and cost.

Reducing the noise from the aspirator decreases noise pollution for other people around you.

The high-pitched whirring sound that the aspirator creates can be irritating or make it difficult to concentrate when you are trying to work, read, watch television, or engage in conversation.

This sound can propagate through walls and closed doors, penetrating throughout the home, office, or studio space.

Soundproofing contains the noise so it doesn’t travel and bother your family members, roommates, colleagues, clients, or others around you.

This creates a much more pleasant and peaceful environment for everyone.

Soundproofing also allows you to use the aspirator anytime without worrying about disturbing others.

You can vacuum at early hours of the morning or late at night while people are sleeping without causing a ruckus.

This increased flexibility in when you can utilize the aspirator without noise constraints can improve your productivity and efficiency.

You can clean at off-hours when traffic in the space is minimized without having to work around others’ schedules and noise sensitivities.

For voice-over artists, singers, musicians, podcasters, or other recording professionals, soundproofing enables you to better hear yourself while recording.

It eliminates the background noise interference from the aspirator so your vocal, instrumental, or conversational tracks are cleaner.

This results in higher quality recordings with minimal distracting noise artifacts. Your mixes will sound more crisp and professional without the whirring sound competing in the background.

Overall, soundproofing your aspirator enhances conditions for yourself as well as those around you. The ability to use it freely without noise disruptions improves quality of life and work.

Being able to clean at odd hours or record audio without the noise bothering anyone outweighs the small hassle and cost required for the soundproofing efforts.

Achieving these benefits for yourself and others around you makes soundproofing a worthwhile investment.

Materials Needed

To properly soundproof an aspirator, you will need to acquire or purchase the following materials:

Acoustic foam panels or insulation provide absorption of noise. The open cell foam structure traps sound waves rather than reflecting them.

The pores in the foam scatter and dissipate the sound energy. Fiberglass, rockwool, or other insulative materials also work well for absorption due to their density and porosity.

These sound dampening materials are used to line any enclosures around the aspirator as well as the room it is used in.

Mass loaded vinyl (MLV) is a heavy, limp vinyl material used to add mass. The weight and density acts as a sound barrier, blocking the transmission of noise through the material.

The limpness allows it to be tightly wrapped around hoses, motors, or other equipment. MLV can also be used in multiple layers to improve effectiveness. Adding mass is key to isolating vibrational noise.

Green glue is a sealant containing damping compounds. It converts vibrational energy into heat when sandwiched between layers of rigid materials.

This constrains and quiets resonance from panels or barriers. Green glue is especially effective at damping and deconstructing vibration noises from fans, motors or contact points.

It reduces the transmission of noise through walls, floors, and panels.

Sealant or caulk is used to seal any air gaps, cracks, or holes in enclosures and barriers. This prevents noise leaks from openings that would allow sound to radiate out.

Acoustic caulk remains flexible after drying to allow absorption of any vibration. Make sure to seal the perimeter of any enclosures completely.

Screws and construction adhesive are needed to assemble any custom enclosures or mounting panels during the soundproofing process.

Ideally the screws would have grommets or rubber washers to prevent transfer of vibrations through the screw holes into the walls.

Having these materials prepared in advance will make the soundproofing process much easier. You can then focus on properly installing them rather than searching for supplies.

Soundproof the Motor and Fan

The motor and fan moving air are responsible for considerable noise that requires thoughtful soundproofing steps. Here are some methods to contain these sounds:

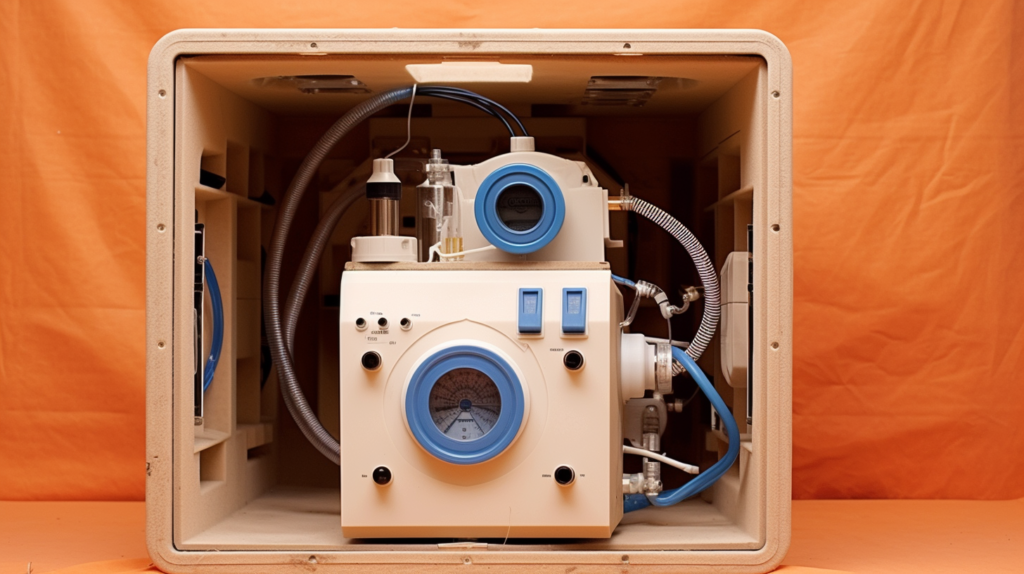

Enclose the motor in an acoustic enclosure or box lined with insulation. Construct walls around the motor compartment using medium density fiberboard, plywood or other rigid panels.

Line the interior cavity completely with 2-3 inches of acoustic insulation such as fiberglass or rockwool. The box contains and traps sound while the insulation absorbs any residual noise.

Add acoustic baffles around the fan opening or ducts leading to/from the fan chamber. These baffles are curved sound-blocking panels that redirect noise coming from the fan.

They can be constructed from rigid materials lined with insulation. Strategic placement around the fan pathways blocks and catches sound waves before they transmit further.

Use quieter replacement fans or place existing loud fans in an insulated box. Upgrading to fans designed for quiet operation reduces noise straightaway.

Alternatively, covering noisy fans in custom sound-absorbing enclosures and linings tames the sounds. This may require some additional motor ventilation considerations.

Lining the full inside of the aspirator canister with acoustic insulation may also help muffle motor and fan noise if space allows.

Just be sure to protect any insulation from moisture and allow proper airflow around the motor.

Fully containing the motor and isolated fan noise stops it radiating outward where it can disrupt people. It also prevents motor vibrations from transferring into the body of the aspirator.

Addressing these primary sources directly makes a significant reduction in the overall noise signature.

Soundproof the Hoses

The hoses connecting to the aspirator readily pick up and transmit noise and vibrations from the forced airflow. Here are effective ways to soundproof the tubes:

Wrap hoses in one or two layers of mass loaded vinyl and thoroughly seal the seams and edges. The MLV adds mass which blocks noise transmission through the hose walls.

It also dampens any vibrations in the hose material itself. Be sure to fully overlap and seal the edge seams to prevent air leaks that could transmit noise.

Use flexible cuffs or rubber grommets for hose connections rather than rigid fittings. Any place the hose connects to the aspirator body, accessories, or vacuum head should have vibration dampening.

These rubberized couplers prevent transfer of vibrations through the connection points.

Further wrap or line hoses in additional absorptive insulation like acoustic foam. The insulation layers underneath the MLV shell capture any remaining noise vibrations and dissipate them.

This may be less necessary if the MLV wrapping provides full coverage.

Suspend or support long hose runs with anchors, braces or hangers to isolate contact with walls. Excess hose movement and contact increases noise generation.

Limiting contact points through elevation decreases this conductance for less opportunity to develop sound.

Sealing and insulating the hoses along their length blocks noise propagation through the tube walls. It also minimizes transfer of vibrations to the surrounding environment.

Keeping the hoses still and suspended further improves sound isolation. Fixing the hoses specifically cuts down ambient noise leakage dramatically.

Soundproof Vibrations

Even small vibrations of an aspirator against walls or floors can generate annoying secondary noise. Soundproofing the contact points helps block transfer of vibrations into surrounding structures. Here are some ways to address it:

Place the aspirator on vibration damping pads or feet. These rubbery mounts absorb vibrations rather than conducting them into the floor.

Neoprene, felt, or foam isolators prevent transfer of resonance through the contact zone. This reduces noise radiation into the environment.

Use rubberized grommets or washers when mounting or attaching the aspirator to walls. The rubber isolates the screws, preventing transfer of device vibrations through the mounting points into the walls.

Hard contact facilitates noise transfer.

Seal the perimeter of the aspirator with flexible caulk or sealant wherever it contacts surfaces. Filling small air channels in the contact zone keeps vibration transmission muted.

The pliable sealant also helps absorb any residual vibrations.

Add mass loading material to surfaces under the aspirator which can dampen transferred vibrations. For example, placing a slab of MLV material underneath or around the unit helps absorb the energy.

Vibrations dissipate in the dense mass rather than turning into noise.

Careful isolation and damping of contact points keeps incidental vibrations contained within the device. Eliminating secondary noise radiation improves the acoustic environment.

Focusing on isolating the aspirator prevents flanking transmission through walls, mounts or adjacent objects.

Alternative Noise Reduction Methods

If fully soundproofing the aspirator is not feasible due to time, cost, or complexity, there are still some alternative approaches to reducing the perceptible noise. Here are a few easier but less thorough options:

Place the aspirator inside a closet or soundproof box when in use to contain the noise. This additional physical barrier limits how far the sound propagates outward. Lining the box provides further damping.

Relocate usage of the aspirator as far away from people as possible. Moving it to a roomy basement, garage, or unused space puts critical distance between it and those you don’t want to disturb.

Only run the aspirator during activities or times that mask its noise. For example, combining use with singing practice, lawn mowing or while you are out of the house can drown out the sounds.

Drape a heavy sound dampening blanket or quilt over the aspirator while running to muffle noise. The mass and density absorbs some sound energy.

Ensure the cover is secure and allows for unobstructed air intake and ventilation.

Wear noise cancelling headphones when aspirating near others as a courteous shielding measure. This protects your own hearing while leaving those around unaffected.

Letting others know to wear protection is also considerate.

While these secondary options may not achieve the same level of soundproofing, they can still provide some helpful acoustic mitigation.

They reduce the need to listen to full strength noise until you can implement more robust sound insulation steps. Any degree of volume reduction typically improves the situation.

Conclusion

Effectively soundproofing an aspirator requires properly containing the major noise sources like the motor, fan, hoses, and contact vibrations.

Strategic use of insulation, isolation, and damping materials helps absorb or block noise transmission through these components.

With some diligent work, an obnoxiously loud aspirator can be transformed into a discreet machine. The resulting ability to use it without disturbing others makes the time and effort worthwhile.

Just be sure to thoroughly identify and remediate all the sound-emitting parts. Fully encapsulating and de-coupling the aspirator from its surroundings curtails the bothersome noise.

Your housemates will thank you for soundproofing it rather than shushing it.