Is your noisy room driving you crazy but you don’t want the mess of tearing down walls?

Nitrile butadiene rubber (NBR) panels allow you to soundproof without wall damage.

Let’s dive in to see how NBR gives you studio-quality acoustics minus the destruction…

Why Soundproof Your Room?

There are many reasons why you may want to soundproof a room in your home without tearing down drywall or otherwise damaging the existing walls. The most common motivations people have for wanting to soundproof without wall damage include:

Improving Privacy

Soundproofing is often desired in order to keep conversations, phone calls, media noise like music or TV, or other sounds from easily travelling out of a room and being overheard throughout the home. It allows you to prevent noises that you want contained in one room from penetrating through walls, under doors, or through ventilation gaps where they can disturb others and lead to a loss of privacy. Soundproofing techniques can dramatically reduce sound leakage, keeping noises in their intended space.

Blocking External Noise

Another driver for pursuing non-invasive soundproofing is reducing the amount of noise that comes into a room from outside sources. These can include traffic noise from nearby roads, construction projects, the sounds of neighbors in attached buildings, barking dogs, maintenance activities like lawn care, and other random loud disruptions. Soundproofing using panels can decrease the penetration of these unwanted external noises that would otherwise make it hard to relax, focus, or sleep. A well soundproofed room provides a peaceful oasis from the intrusion of the outside world.

Lowering Volume

When certain noisy activities are necessary, like playing musical instruments, listening to music or movies at high volumes, gaming with booming audio effects, operating noisy equipment like treadmills, or engaging in projects that produce noise, soundproofing contains and reduces the transmission of these loud sounds throughout the rest of the home where they might disturb other members of a household or even next door neighbors if in close proximity. Panels prevent noise “leakage” from loud volumes so others don’t hear it as easily. This allows one to enjoy media and activities at the desired levels without negatively affecting those nearby.

Converting Space

When transforming a room into a specialized use case that relies on controlling noise, such as building a home music studio, setting up a home theater, creating a video recording studio, or converting a garage or shed into a workshop, the amount of soundproofing becomes critical for proper function. The room must have acoustic isolation and noise control far beyond what standard household construction provides. In many cases extensive soundproofing upgrades would require demolishing and rebuilding walls. Panel solutions avoid this destruction and preserve the integrity of the existing structure.

Protecting Walls

Tearing down sections of drywall and rebuilding internal wall assemblies is inherently destructive. It creates dust and debris requiring cleanup and disposal. New framing and drywall finishing is also an intensive process requiring skilled labor for a polished look, as opposed to a clearly DIY amateur aesthetic. Using externally mounted soundproofing panels prevents damage to existing walls, maintaining architectural integrity, avoiding mess, keeping costs down, and still achieving significant noise isolation. This non-invasive approach is preferable when feasible.

Enhancing Function

There are some scenarios where a room simply will not function properly for the intended use without sizable reductions in noise coming in and out of the space. For example, setting up a home office in a spare bedroom that’s exposed to significant external noise as well as sounds from the rest of the home makes it difficult to take calls, record podcasts, or video conference. Likewise, a TV room won’t provide an immersive viewing experience if noise constantly filters in. Upgrading the soundproofing using non-damaging methods enhances functionality.

As you can see, there are a wide variety of motivations that lead homeowners, renters, and building occupants to seek out ways to effectively soundproof rooms without tearing down existing drywall or otherwise harming walls. The common thread is a desire to control noise transfer for privacy, external noise blocking, volume containment, specialized use cases, preservation of building materials, and optimizing functionality.

Challenges of Non-Invasive Soundproofing

While the benefits of room soundproofing are clear, there are notable challenges involved with achieving meaningful noise control using non-invasive techniques and materials that avoid alteration of walls.

The most significant obstacle is finding products capable of adequately absorbing and blocking sound waves and vibrations without requiring major modifications like removing wall layers or building secondary interior walls. There are a few common options frequently used in surface level soundproofing with limited success:

Mass Loaded Vinyl (MLV)

MLV is a thin yet dense vinyl material containing fillers that increase its weight. This added mass enhances noise blocking capabilities when installed on walls. However, MLV lacks flexibility and requires additional supportive layers. It also does little to address lower frequency noise and has minimal absorption properties.

Cork

Cork panels made from compressed cork flakes provide some sound dampening thanks to the elasticity of the material that dissipates vibrations. However, cork lacks sufficient mass to block mid and low frequency sounds. It reduces rather than eliminates noise transfer. Large cork panels can also be difficult to securely mount on walls without an air gap.

Foam Panels

Polyurethane or polystyrene foam panels work to absorb and dissipate higher frequency sounds thanks to their porous, open-cell structure. But foam lacks the mass and isolation necessary for blocking lower frequency sounds. Foam panels alone leave considerable noise leakage making their soundproofing contribution moderate at best.

Fiberglass

Fiberglass insulation when enclosed in cavities can enhance soundproofing through its high absorption and friction damping. But fiberglass does not create a sturdy sound barrier and requires additional containment layers. Used alone on open walls it performs poorly and lacks noise blocking depth.

These common surface solutions for DIY soundproofing all provide measurable improvements under optimal conditions. However, they share inherent physical limitations that prevent them from truly minimizing noise transfer on their own without invasive structural modifications. There are also challenges with difficult installation and inferior acoustic performance across the full frequency spectrum.

Advanced soundproofing materials are required to appropriately address these deficiencies and meet the performance levels desired for noticeably quieter, isolated residential and commercial rooms. This brings us to the category of materials known as limp mass dampers, with nitrile butadiene rubber being the ideal choice.

What Are Nitrile Butadiene Rubber Soundproofing Panels?

Nitrile butadiene rubber (NBR) is a synthetic co-polymer that has gained considerable popularity and use in industrial applications as well as consumer goods due to its advantageous properties, including significant noise dampening capabilities. NBR acoustic panels utilize this unique material in layers to create an effective sound barrier that outperforms other options.

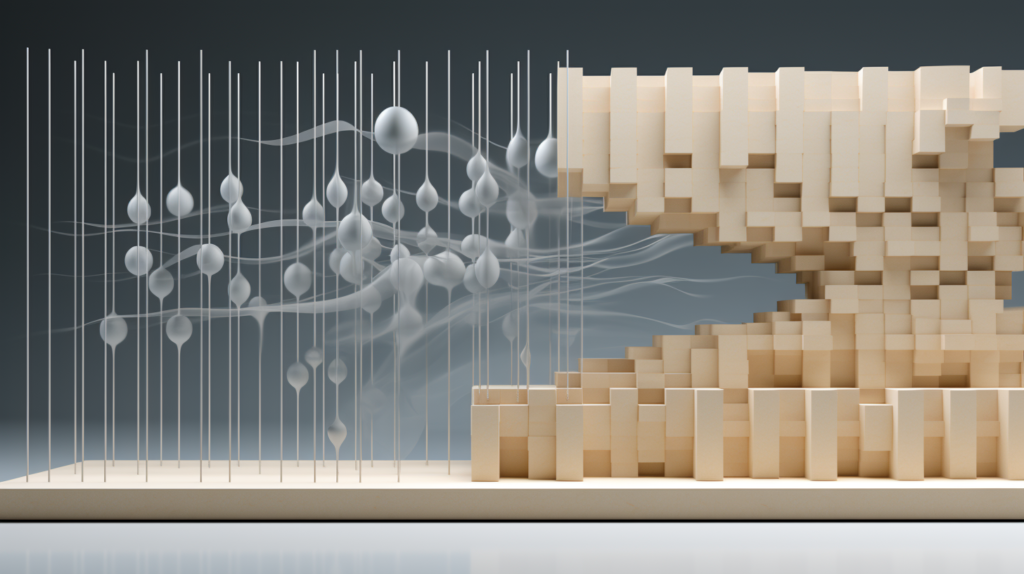

On a molecular level, NBR contains both nitrile and butadiene components. The nitrile contributes rigidity and resistance to oils and abrasion. The butadiene provides elasticity and flexibility. This molecular structure gives NBR panels the ideal traits for soundproofing performance.

The panels contain configurations of dense NBR formulated to balance mass, or limpness, with damping. This allows the material to excellently dissipate kinetic sound energy and attenuate both airborne and structure-borne noise. The flexibility prevents the brittle rigidity of something like MLV that requires additional supports.

Unlike more porous absorbents like fiberglass insulation or acoustic foam, NBR acts through blocking noise via its mass and vibration damping traits rather than just sound energy absorption. This gives it vastly superior performance across the full spectrum of audible sound frequencies – from bass and mid-range to high frequencies.

In contrast to decoupling methods like room-in-room assemblies, NBR panels create a unitary noise barrier on the actual existing walls. The panel mass literally blocks sound waves and prevents them from transferring through the wall assembly. This occurs through the process of reducing sound wave amplitude as the waves pass from lower acoustic resistance air into the higher acoustic resistance of the limp yet dense NBR material.

Additionally, NBR’s elastic properties convert the kinetic energy of sound and vibrations into thermal energy which is dissipated as low levels of heat. This transformation again prevents sound energy from being transmitted through the material.

The combination of these acoustic phenomena gives NBR unmatched noise control capabilities compared to common soundproofing products. NBR also contains anti-microbial properties for added defense against mold, mildew, and bacterial growth. And most NBR panels feature a protective coating or exterior film which protects the inner soundproofing layers from damage.

NBR acoustic panels come in thicknesses ranging from 1 inch to 4 inches, with 2 inch being the most popular depth for general use residential and commercial soundproofing needs. Custom sizing and modular configurations are available for retrofitting on any wall dimensions.

Next we will cover proper installation practices to achieve maximum non-invasive noise reduction utilizing NBR panels. But in summary, NBR provides unparalleled performance and ease of use forUpgrade soundproofing walls without reconstruct

How To Install NBR Panels

Proper installation of NBR panels is crucial for enabling them to deliver their full noise blocking potential without requiring major wall alterations or damage. Here are some best practices to follow:

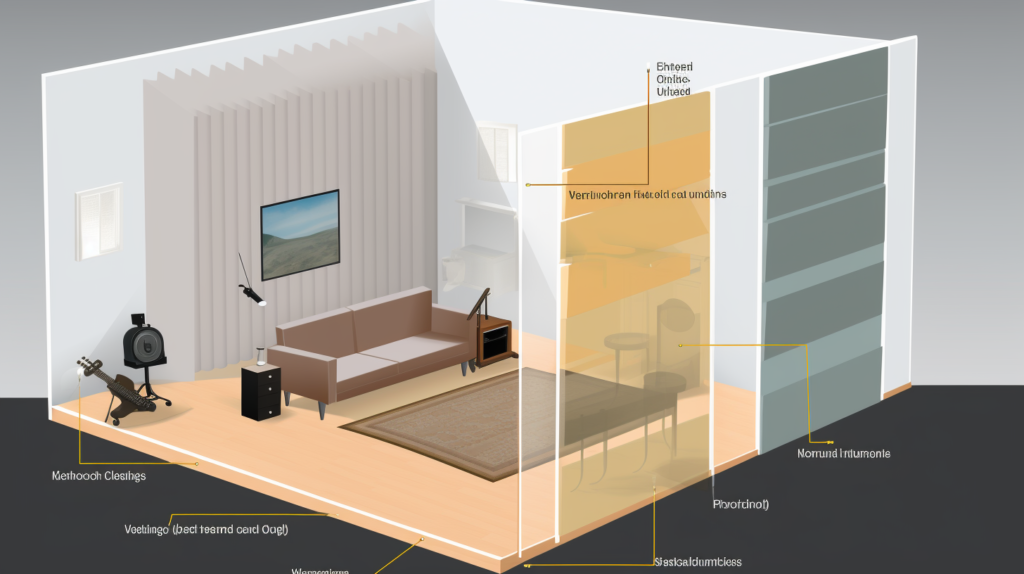

Edge-To-Edge Coverage – It is vital that panels get mounted flush against one another along the perimeter of walls, floor to ceiling and wall to wall. Even small gaps where panels meet or at edges effectively compromise performance by allowing noise to flank around the material. Continuous coverage is key.

Secure Mounting – NBR panels should be firmly fixed to existing walls using either a very high bond adhesive backing, or mechanical fasteners like screws or toggles combined with adhesive caulking at seams. This prevents any vibration or sound leakage between the panels and walls that could transmit noise.

Outlet Treatment – When covering over existing electrical boxes or switches, the panels must be carefully cut to surround them neatly. Any remaining gaps should then be sealed with acoustic caulk which blocks sound flanking through these openings. Low expanding foam can also assist with air tight seals.

Additional Layers – Doubling up panels by adding a second layer effectively doubles the limp mass sound barrier. This can significantly enhance performance, especially for blocking lower frequency noise like heavy bass. Use high strength bonding adhesive or furring strips between layers for optimal density and wave blocking.

Ceilings and Floors – For truly isolated rooms it is ideal to install panels not just on walls but also across ceilings below, and floors if possible. This eliminates any flanking path for noise transmission, containing sound in a cocoon of NBR panels. Use adhesive and seal edges with acoustic caulk or trim.

Room-In-Room Assemblies – The ultimate in soundproofing utilizes a room-within-a-room concept where floating walls are built an inch or two inside the existing walls with the gap packed with insulation like rockwool or Roxul. NBR panels can line these floating walls and deliver studio levels of isolation.

By following these guidelines carefully you can achieve tremendous noise reduction from NBR panels without altering the existing room walls whatsoever. Just be diligent about full coverage without gaps, multi-point adhesive bonding, and very solid mounts. Done properly, NBR will excel at its sound blocking mission.

The Impact Of NBR Panels On Noise

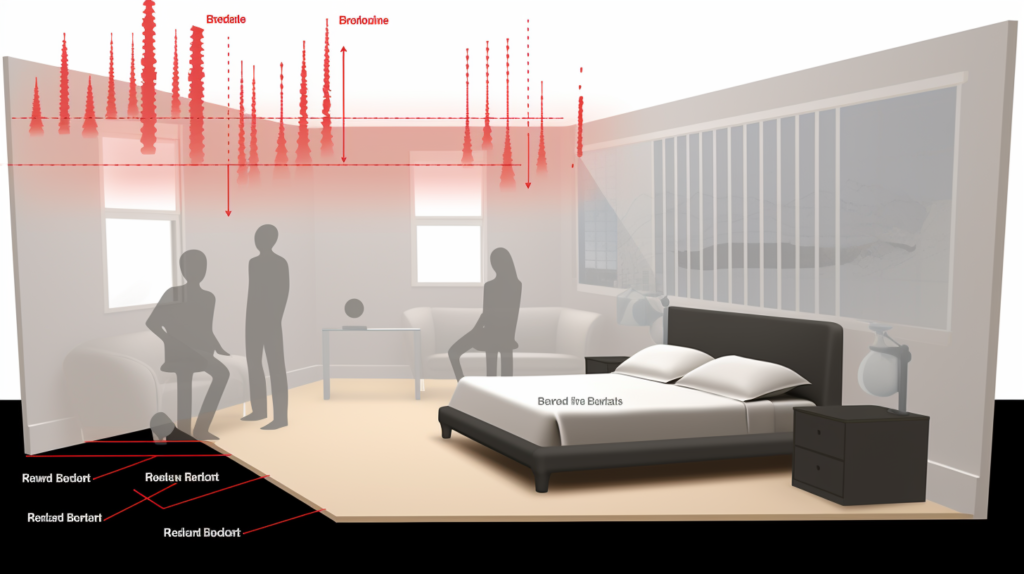

The exact amount of sound and noise reduction achieved by installing NBR acoustic panels depends on the specific product attributes like thickness, density, and installation coverage quality. However, in general using NBR panels properly can decrease noise transfer through walls by 50% to 80% or more.

As an example, a high grade 2 inch thick NBR panel from Stop Noise mounted edge-to-edge throughout a room’s surrounding wall surfaces will typically reduce airborne sound transmission by 20 to 30 decibels, and structure borne noises like footsteps and knocking by 30 to 40 decibels.

These noise decreases represent major improvements to interior acoustics and ambient volumes. Loud music or machinery that could be clearly heard through walls will become barely audible background muffles. Neighbor voices and traffic noise penetrating into the room decrease from distracting volumes to faint hums.

Doubling up panels by adding a second layer can further enhance performance, especially for blocking lower frequency noise like home theater bass. Room-within-room assemblies utilizing NBR panels often achieve nearly the same isolation performance as full studio construction builds.

As a useful guideline, a 10 decibel decrease cuts the human perception of loudness in half. Going from no soundproofing to properly mounting quality NBR panels results in approximately 90% less audible noise transmitting through the walls. The difference in acoustic privacy is night and day.

It’s important to note that these optimal results depend on careful installation with no gaps between panels and steps taken to also soundproof ceilings, doors, windows, and floors. Leaving any holes or cracks severely reduces NBR’s remarkable noise control capacities by allowing flanking paths. Use trim, caulk, insulation and other sealing tactics to close potential openings.

Additional Soundproofing Strategies

While NBR panels will carry the workload when it comes to blocking noise transmission through walls, you can complement their performance with these additional soundproofing techniques:

Thick Curtains – Adding heavy drapes or layered curtains over windows boosts sound isolation, especially helpful for blocking outside noise sources. Ensure full coverage from top to bottom with at least 6 inches of fabric overlap when closed.

Door Seals – Seal gaps under exterior doors with door sweeps and beneath interior doors with thresholds. Also use adhesive door seals and weatherstripping to prevent sound escape. Make the door perimeter airtight.

Thick Rugs – Large area rugs with thick underpadding help absorb errant reflections and airborne noise within rooms. This reduces echos and contains sounds.

Acoustic Insulation – Packing soundproofing insulation like rockwool into wall and ceiling cavities (and unused outlet boxes) cuts down on incidental noise flanking for improved isolation.

Eliminate Leaks – Be sure to fully seal any vents, pipes, conduits, wiring holes, etc that penetrate walls, ceilings, or floors. This prevents sound transmission through these pathways.

Combined properly with NBR panels, these additional steps complete the soundproofing process resulting in dramatically quieter interior rooms free of external distractions. Peaceful spaces for focused work and enjoyable entertainment sans noise.

Conclusion

Nitrile butadiene rubber (NBR) acoustic panels provide high performance, non-invasive soundproofing unmatched by common materials like MLV, cork, foam, and fiberglass. NBR’s unique physical properties excel at blocking both airborne noise and structure-borne vibrational sound transmission through walls and ceilings.

Full wall coverage and proper installation practices are vital for NBR panels to deliver their full potential noise blocking capabilities. But when applied correctly, they can reduce noise transfer by 50% to 80% or more compared to no treatment. This allows transforming loud and disruptive rooms into peaceful sanctuaries without any mess or damage from major demolition and wall reconstruction.